News

-

Revealing The Efficiency Of Runxiang Machinery Continuous Casting Equipment

Introduce: In this article, we will delve into the fascinating world of continuous casting equipment, its key role in the steel industry, and how Runxiang Machinery excels in providing first-class equipment and accessories for various industries. With our mechatronic-hydraulic expertise, we have ...Read more -

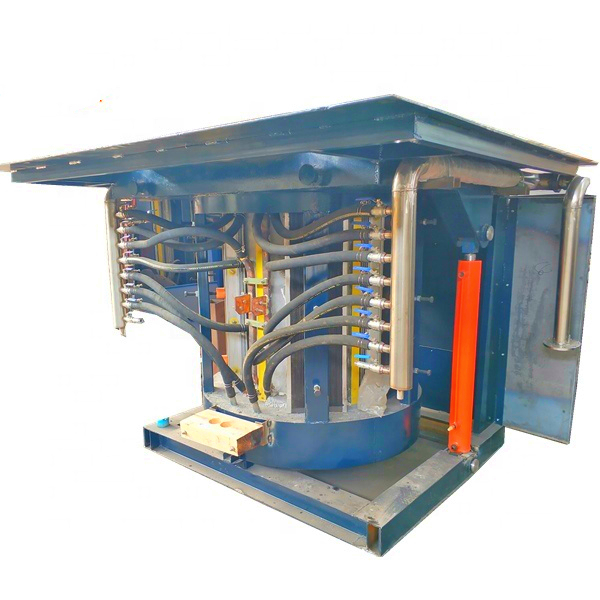

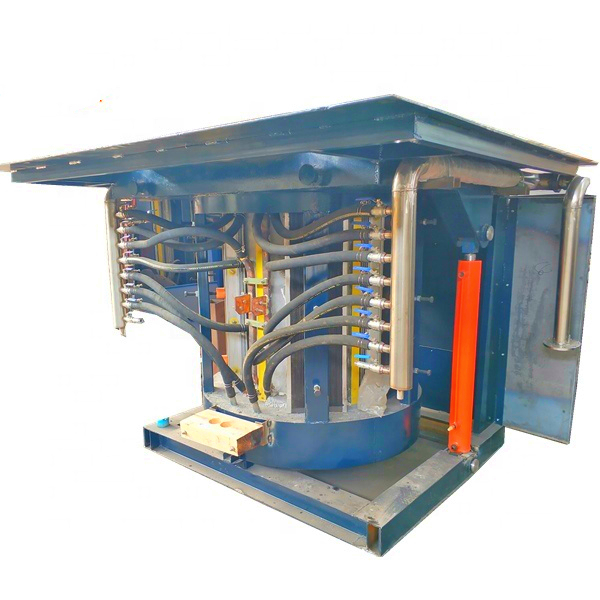

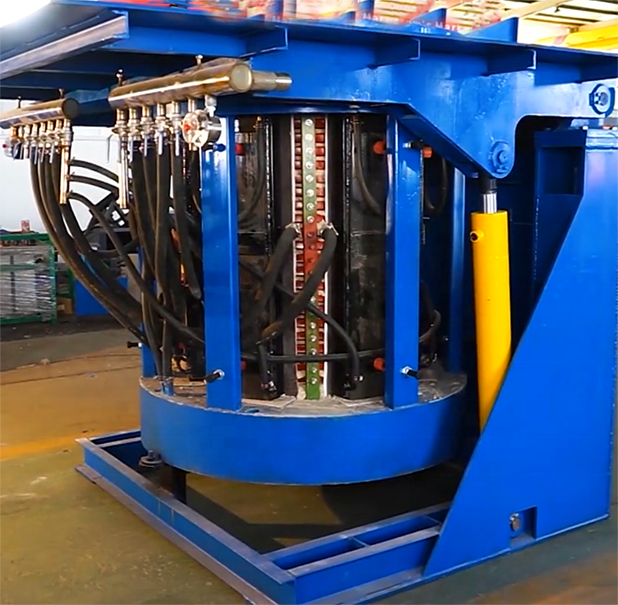

Using Intermediate Frequency Furnace to Improve Casting Efficiency

In the metal foundry industry, the efficiency and effectiveness of the melting process is critical to achieving high-quality castings. Industrial melting furnaces play a pivotal role in this process, and one of the furnaces that has gained popularity is the intermediate frequency furnace. At Runx...Read more -

Continuous Furnaces: A Versatile Solution for Heating Furnace

In today’s fast-growing metallurgical industry, achieving efficient and precise metal smelting and heat treatment processes is of paramount importance. As technology has advanced, heating furnaces have become an integral part of various industries, providing reliable and consistent heating ...Read more -

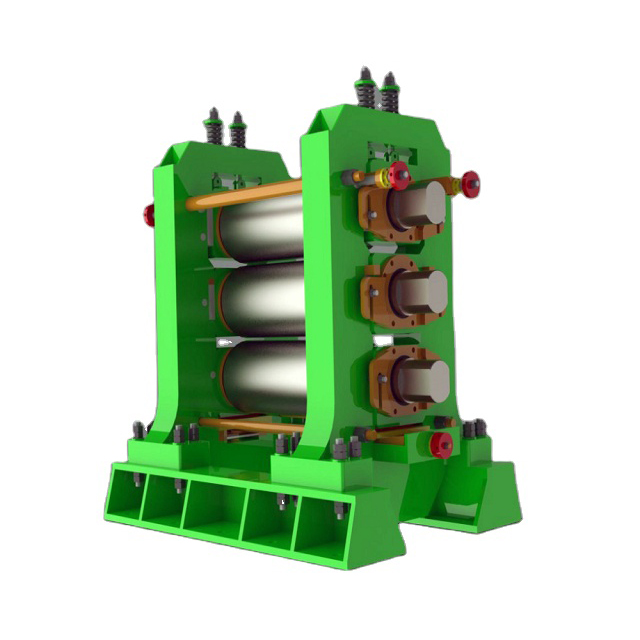

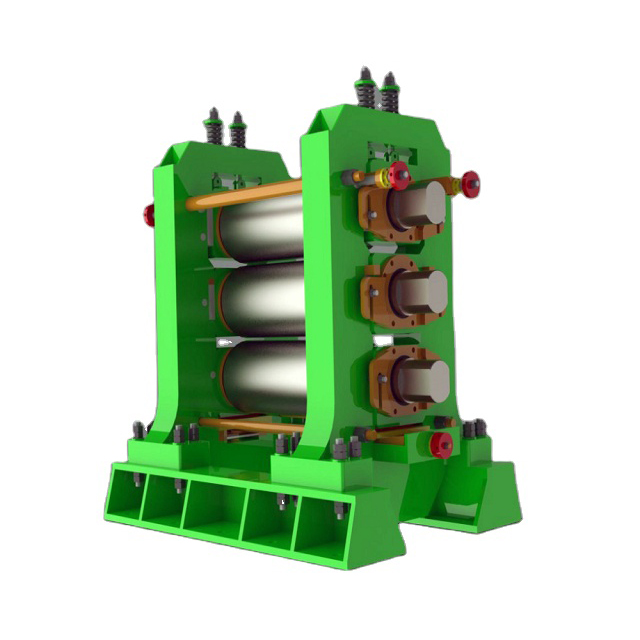

Guangxi Runxiang Machinery Mill Rolls Are Excellent

Welcome to our blog, where we explore the extraordinary world of mill rolls. Today, we delve into the fascinating field of roller mill manufacturing, highlighting the expertise of Guangxi Runxiang Machinery. Known for their high quality raw materials and precision engineering, their roller mills ...Read more -

Three High Rolling Mill: Revolutionizing the Steel Rolling Equipment Process

Rolling mills are the backbone of the metal production industry, processing raw materials into various shapes and sizes. One of the groundbreaking pieces of equipment was the three high rolling mill, renowned for its efficiency, versatility and precision in rolling steel. In this blog, we will de...Read more -

How Does A Continuous Casting Machine Work?

Continuous casting is a process that has revolutionized the production of high-quality steel products. The process is to continuously cast high-temperature molten steel into a slab with a certain cross-sectional shape and size. The equipment used to realize this production process is called conti...Read more -

Gas Furnace: The Backbone Of Metal Smelting Equipment

Runxiang Machinery is a leading manufacturer of metal smelting equipment, offering a wide range of options to customers looking for high-quality solutions for their metal processing needs. Among their products, gas producers stand out as a reliable and versatile option that can meet the needs of ...Read more -

The Importance Of Dust Collectors In Metal Smelting Equipment

When it comes to metal smelting equipment, dust collectors cannot be ignored. These industrial dust collectors play a vital role in maintaining a safe and efficient production process. Runxiang Machinery is well aware of the importance of providing complete sets of equipment and accessories for m...Read more -

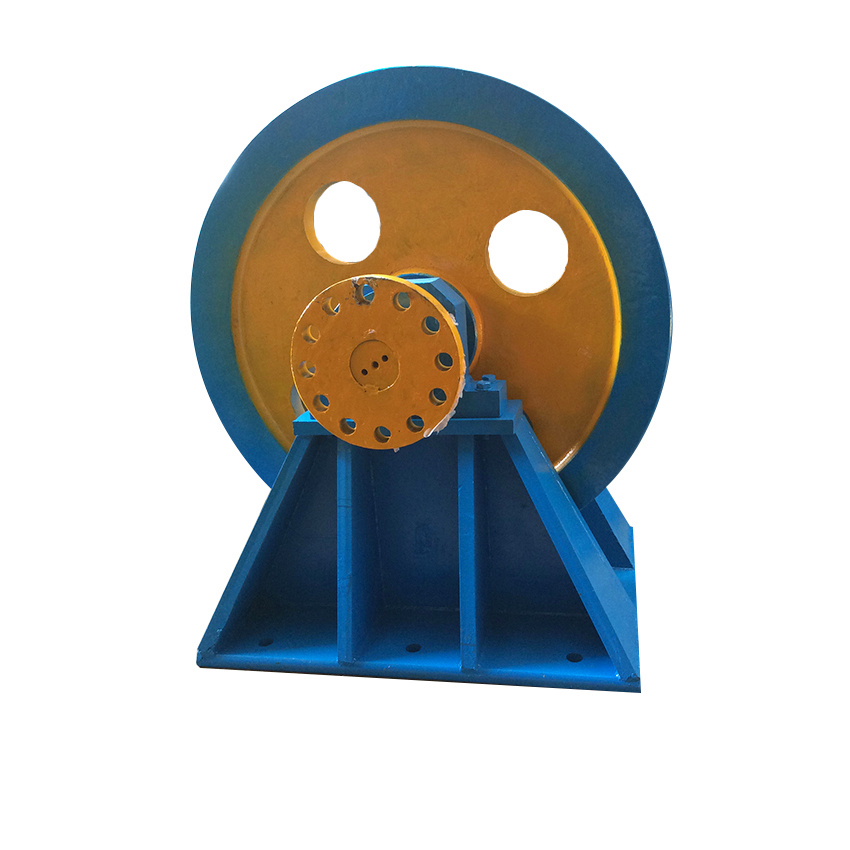

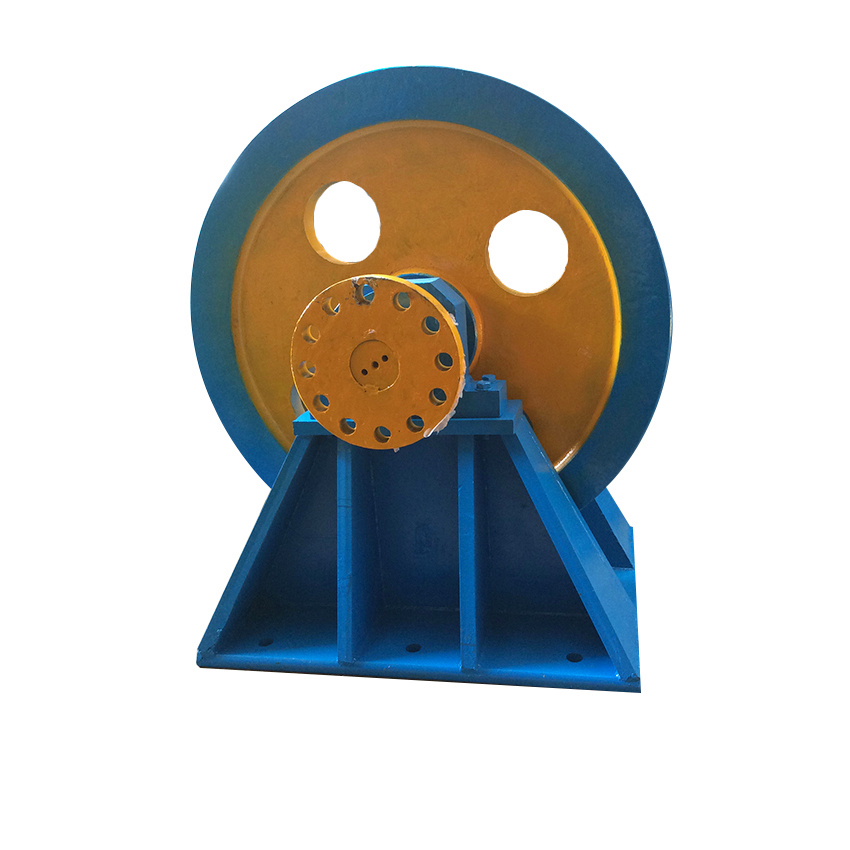

Fly Wheel: An Essential Component In Rolling Mill Equipment

In industrial manufacturing, rolling mills play a vital role in the production of high-quality steel bars. These factories require custom industrial equipment that can handle extreme pressure and heat to form metal into the desired shape and size. For these machines to run efficiently and effecti...Read more -

Back Up Roll Mills: Provide Maximum Support And Stability For Workpieces

Backup rolls are an important part of rolling mills used in the metallurgical and steel industries. Their main role is to provide support and stability to the workpiece during rolling, ensuring smooth and efficient operation. At Runxiang Machinery, we understand the critical role backup rolls pla...Read more -

The Importance Of High Speed Flying Shears

Flying shears are indispensable equipment in steel rolling equipment and play a vital role in the metal processing industry. In particular, high speed flying shears are highly sought after for their ability to quickly cut through iron plates, steel pipes and paper rolls. These shears are an indis...Read more -

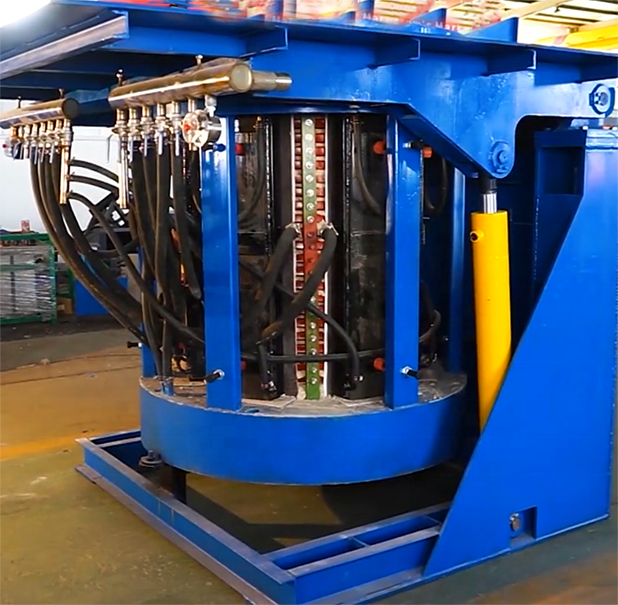

Why Steel Shell Furnace Is So Popular

Steel shell furnace, also known as intermediate frequency furnace, is an advanced metal smelting equipment, which is highly sought after by all walks of life for its excellent performance and performance. Guangxi Runxiang Machinery is a well-known manufacturer of these furnaces with extensive exp...Read more