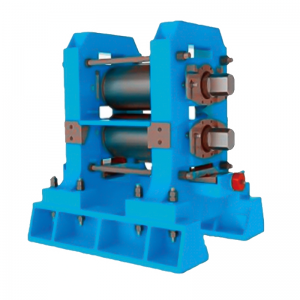

Industrial Aluminum Plate Rolling Mill

| Product Name | Aluminum Plate Rolling Mill | Rolling Form | Cross-Rolling |

| Type | Cold Rolling Mill | Rolling Shape | Strip |

| Brand | Runxiang | Processing Customization | Yes |

| Rolling Temperature | Cold Rolling | Place Of Origin | Guangxi, China |

Plate rolling mill: rolling single sheet extra thick plate, thick plate, medium plate and thin plate rolling mill.

Features.

1. Aluminum plate rolling mill is made of real material, high production and energy saving, easy to operate.

2. Sturdy and durable, stable operation, quality assurance and long service life.

3. A variety of specifications to choose from, can also be customized according to customer needs.

4. Reliable after-sales service, no worries.

Hot-rolled plate including thick plate, medium plate (coil), hot-rolled thin plate (coil), hot-rolled medium and wide band steel, hot-rolled narrow strip, etc.. Corresponding mills are thick plate mill, furnace coil mill, hot strip mill, strip mill, etc., which single or double-stand hot-rolled sheet mill is mostly used to roll thick specifications hot plate into thin specifications hot plate, the direct use of billet less, and does not increase the actual plate production, and therefore not counted in the hot rolling capacity. As a variety of hot-rolled sheet varieties of market each other there is a greater impact, and thus we will be a combination of various types of hot-rolled sheet products to see the overall capacity of China’s hot-rolled sheet situation.

Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd. was established in May 2021. It is a national high-tech enterprise specializing in R&D, manufacturing, sales and service of steel rolling production line equipment. At present, it has production supporting processes such as steelmaking, cast steel, heat treatment, mechanical processing, and surfacing welding, forming an integrated industrial chain of smelting, casting, metal heat treatment, and mechanical processing.

The company covers an area of 20,000 square meters, and the workshop covers an area of 10,000 square meters. There are more than 50 employees, including 5 core scientific researchers and 3 engineers. It can produce 1,000 sets of various large, medium and small equipment per year. The company builds a special production service plan based on international standards, starting from R&D and design, to product manufacturing, and subsequent installation and after-sales service, to provide customers with world-class products and supporting services.