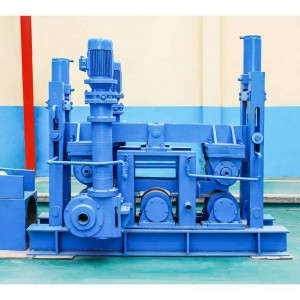

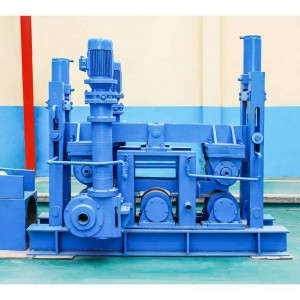

Continuous casting machine

-

Steel Billet Continuous Casting Machine

Packaging Details:Wooden case packing

Port:Tianjing

Lead time:

Quantity(sets) 1 – 1 >1 -

Continuous Casting Machine For Sale

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Steel Billet Continuous Casting Machine

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Continuous Caster In Steel Making

Rolling temperature:>950℃

Motor power:2.2KW-50KW

-

Industrial Continuous Caster

- Drawing speed:1.5m-4m/min

- Garden billet size:φ60~φ250

- Billet size:60×60~250×250

- Model:R3000~R8000

- Product description: Continuous casting machine production process. High temperature molten steel continuous casting to one or a set of water-cooled copper mold, steel along gradually solidified into a shell surrounding

-

Continuous Caster

- Drawing speed:1.5m-4m/min

- Garden billet size:60~250

- Billet size:60×60~250×250

- Model:R3000~R8000

- Product description: Continuous casting machine production process. High temperature molten steel continuous casting to one or a set of water-cooled copper mold, steel along gradually solidified into a shell surrounding

-

Continuous casting machine

Continuous casting machine production process. The high-temperature molten steel is continuously poured into one or a group of water-cooled copper crystallizers, and the molten steel is gradually solidified into a blank shell along the periphery of the crystallizer. After the steel liquid level rises to a certain height and the blank shell solidifies to a certain thickness, the tension leveler pulls out the blank, and the slab is cooled by water spraying in the secondary cooling area to compl... -

Continuous Casting Machine

- Drawing speed:1.5m-4m/min

- Garden billet size:φ60~φ250

- Billet size:60×60~250×250

- Model:R3000~R8000

- Product description: Continuous casting machine production process. High temperature molten steel continuous casting to one or a set of water-cooled copper mold, steel along gradually solidified into a shell surrounding

-

Wear parts of continuous casting machine

Main process flow is: from molten steel ladle outflow, first into the tundish, then into arc crystallizer, formed in crystallizer slab roller downward movement along the arc, arc movement by water spray cooling, until the complete or partial solidified, then casting to the horizontal tangent point into the machine, then use the flame cutting handlebar slab cutting length, from the horizontal loading.My company’s continuous casting machine production of billet mainly have, billet, garden...