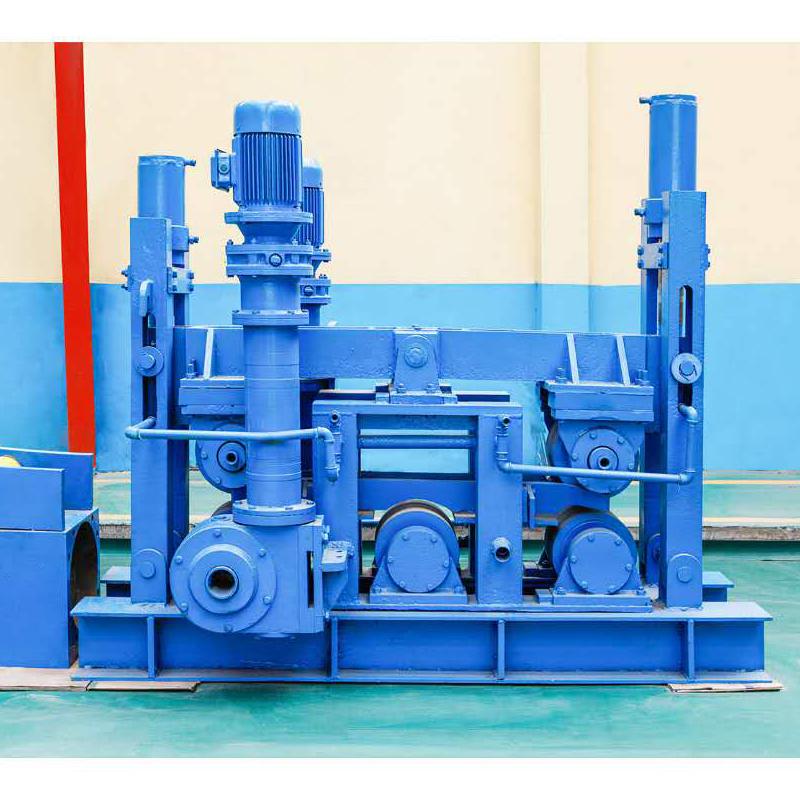

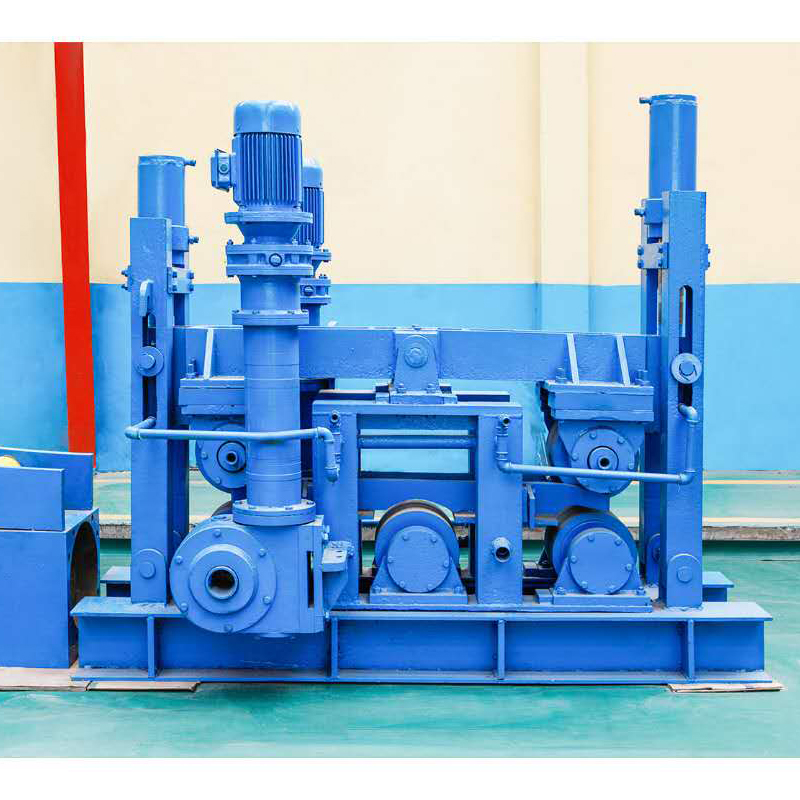

Industrial Continuous Caster

Continuous casting machine production process. The high-temperature molten steel is continuously poured into one or a group of water-cooled copper molds, and the molten steel gradually solidifies along the periphery of the mold into a billet shell. The billet is pulled out, and the billet is completely solidified by water spray cooling in the secondary cooling zone, and is cut to length by the cutting device according to the requirements of rolling. This process of directly pouring high-temperature molten steel into billets is called continuous casting. Its appearance has fundamentally changed the ingot-rolling process that has dominated for a century. Because it simplifies the production process, improves the production efficiency and metal yield, saves energy consumption, greatly reduces the production cost, and has the advantages of good billet quality and other advantages. In today’s steelmaking enterprises, whether it is long-process steelmaking or short-process steelmaking, the equipment of continuous casting machines is almost inevitable.

Feature:

1. Senior scientific research personnel design, R & D and production technology are guaranteed.

2. Sufficient inventory, can be mass-produced and shipped.

3. Various specifications, can be customized according to customer requirements.

4. After-sales service guarantee, to provide customers with first-class products and supporting services.

Application:

FAQ:

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.