Industrial Rolling Mill Machine Rack

| Product Name | Rolling Mill Rack | Application Field | Rebar Rolling Production Line |

| Brand | Runxiang | Origin | Guangxi, China |

| Purpose | Place And Install Roll Bearing Housings And Rolls, Etc. | Whether To Customize | Yes |

The rolling mill rack is an important part of the working frame, and the roll bearing housing and the mill roll adjustment device are all installed on the frame. The frame must have sufficient strength and rigidity to bear the rolling force.

According to the type and working requirements of the rolling mill, the rolling mill frame is divided into two types: closed type and open type.

1. The role of the rack

(1) Function: Use all the parts in the working stand such as uninstalled rolls, roll bearings, roll adjustment devices and guide devices, and bear the full rolling force.

(2) Status: The stand is the largest part in size and weight in the working stand of the rolling mill. The roll bearing and roll adjustment device are installed on the stand, and the stand bears the huge rolling force.

2. Type of rack

(1) Composition: The frame is mainly composed of the left and right arches, the connecting beam connecting the two arches, the slide plate located inside the window of the archway and other components. Since the archway is the main part of the frame, only the structure, parameters and strength of the archway are introduced.

(2) Classification of rolling mill archways

Closed archway and open archway

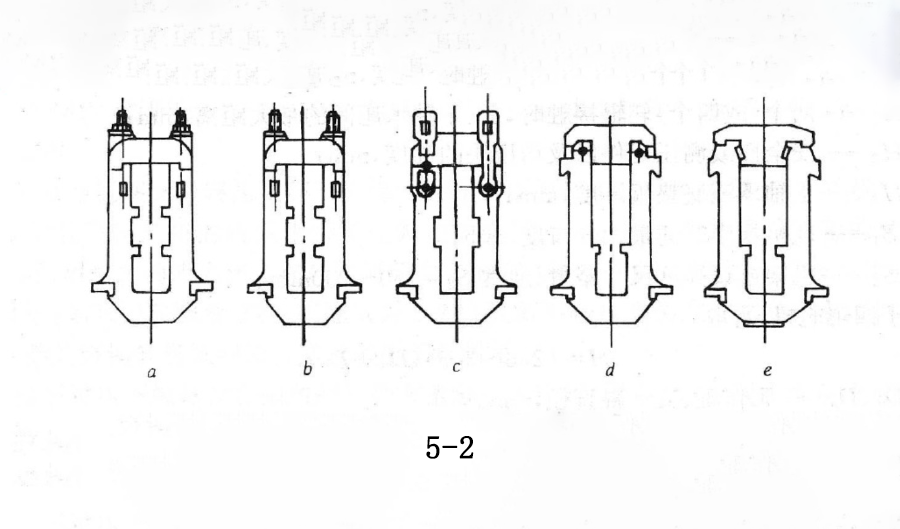

3. The archway of the closed rack

As shown in Figure 5-1, the closed frame is an integral frame with high strength and rigidity. Closed stands are mainly used for blooming mills, slab mills and strip mills with large rolling forces. For strip rolling mills, in order to improve rolling precision, higher frame stiffness is required. For some small and wire rod mills, closed frames with better rigidity are often used to obtain better quality of rolled products. The working frame of the closed frame is used. When changing the roll, the roll is drawn out or loaded from the window of the frame along its axis direction. This kind of rolling mill is generally equipped with a special roll changing device.

As shown in Figure 5-1, the closed frame is an integral frame with high strength and rigidity. Closed stands are mainly used for blooming mills, slab mills and strip mills with large rolling forces. For strip rolling mills, in order to improve rolling precision, higher frame stiffness is required. For some small and wire rod mills, closed frames with better rigidity are often used to obtain better quality of rolled products. The working frame of the closed frame is used. When changing the roll, the roll is drawn out or loaded from the window of the frame along its axis direction. This kind of rolling mill is generally equipped with a special roll changing device.

a. Most of them are integrally cast. When the size and weight of the archway are too large and limited by casting conditions or transportation conditions, electroslag welding is used to weld it.

b. It has high strength and rigidity.

c. It is mainly used on rolling mills with high rolling pressure or strict requirements on the size of rolled pieces, such as roughing mills and strip mills.

d. When changing the rolls of the closed archway, the rolls enter and exit from the window of the archway along the axial direction.

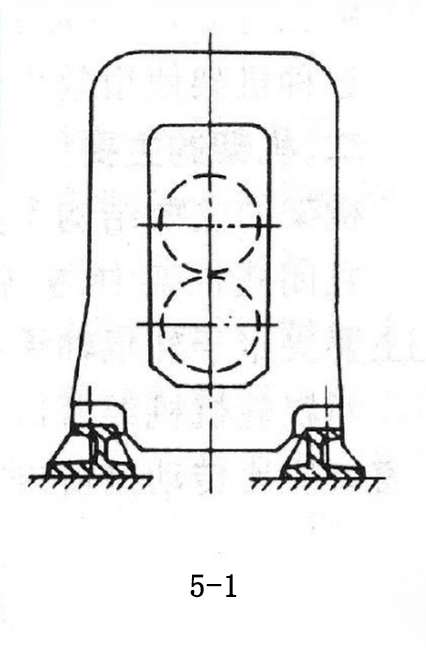

4. The archway of the open rack

The open frame is composed of the frame body and the upper cover (Fig. 5-2). It is mainly used in horizontal section steel rolling mills, and its main advantage is that it is convenient to change rolls. Because, if a closed stand is used on a horizontal section mill, it is very difficult to change the roll along the axis of the roll due to the obstruction of the adjacent stand and the coupling shaft. The open frame is adopted, and the roll can be easily lifted out or loaded as long as the upper cover is removed. The main disadvantage of open racks is less rigidity. The main key that affects the rigidity of the open frame and the speed of changing rolls is the connection method of the upper cover.