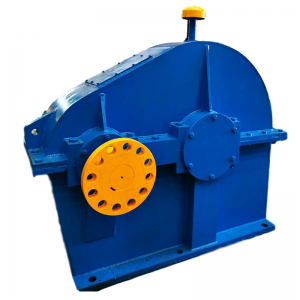

Industrial Gear Speed Reducer

| Product Name | Reducer | Material | Wear-resistant steel |

| Brand | Runxiang | Category | Gear reducer |

| Processing custom | Yes | Gear type | Cylindrical gear reducer |

| Drive | Electric | Installation form | Horizontal |

| Principle | Water-cooled | Layout | Coaxial type |

| Color | Green | Tooth surface hardness | Hard tooth surface |

| Paint | Environmental protection | Usage | Lifting, mining, oil and other industries |

The mill reducer is a reducer that should be placed horizontally and transmitted to the mill by a universal coupling.

The input shaft of the Industrial speed reducer is connected to the motor by a drum tooth coupling and is transmitted to the mill by a universal coupling through a reduction shunt respectively.

Advantage:

1. Stable output and long service life.

2. High load capacity, low noise operation.

Features:

1. Industrial speed reducer can be customized according to requirements.

2. Sufficient stock and quick delivery.

3. Factory supply, good quality and low price.

4. Use of high-quality materials, the housing upgrade thickening treatment, strong and sturdy, not easy to rust.

5. Copper core motor, fast speed and high efficiency. The overall performance is stable, high quality, low power consumption.

6. Smooth running, low noise, stronger load-bearing.

7. Can be applied to a variety of scenes, better experience.

Product details.

1. Short production cycle, fast delivery, to ensure about regular delivery.

2. Control the quality, using testing equipment for strict testing of products to ensure the quality of products.

3. Strength factory, excellent quality。

ZD reducer product features ZD reducer is a single-stage involute cylindrical gear reducer, ZDH is a single-stage circular circular cylindrical gear reducer, ZDSH is a single-stage double-circular cylindrical gear reducer.

The company covers an area of 20,000 square meters, the plant area of 10,000 square meters. There are more than 50 employees, including 5 core scientific researchers and 3 engineers. We can produce 1000 sets of various large, medium and small equipment annually. Based on international standards, the company builds special production service programs, from R&D and design, to product manufacturing, to subsequent installation and after-sales service, to provide customers with world-class products and supporting services.