Intermediate Frequency Furnace

The eddy current generated by the IF furnace also has some properties of the intermediate frequency current, that is, the free electrons of the metal itself flow in the metal body with resistance to generate heat. A three-phase bridge type fully-controlled rectifier circuit is used to rectify alternating current into direct current. For example, a metal cylinder is placed in an induction coil with alternating intermediate frequency current. The metal cylinder is not in direct contact with the induction coil, and the temperature of the energized coil itself is very high. Low, but the surface of the cylinder is heated to the point of redness and even melting, and the speed of this redness and melting can be achieved only by adjusting the frequency and the strength of the current. If the cylinder is placed in the center of the coil, the temperature around the cylinder will be the same, and the heating and melting of the cylinder will not produce harmful gases or pollute the environment with strong light.

Working principle:

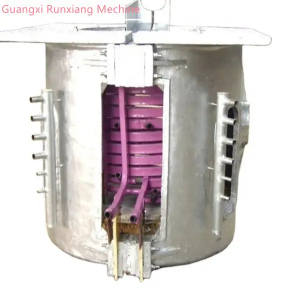

The intermediate frequency furnace is mainly composed of a power supply, an induction coil and a crucible made of refractory materials in the induction coil. The crucible is filled with metal charge, which is equivalent to the secondary winding of the transformer. When the induction coil is connected to the AC power supply, an alternating magnetic field is generated in the induction coil, and its magnetic lines of force cut the metal charge in the crucible, and an induced electromotive force is generated in the charge. Since the charge itself forms a closed loop, the secondary winding is characterized by only one turn and is closed. Therefore, an induced current is generated in the charge at the same time, and when the induced current passes through the charge, the charge is heated to promote its melting.

The intermediate frequency electric furnace uses the intermediate frequency power supply to establish an intermediate frequency magnetic field, so that the induced eddy current is generated inside the ferromagnetic material and generates heat, so as to achieve the purpose of heating the material. The intermediate frequency electric furnace adopts 200-2500Hz intermediate frequency power supply for induction heating, smelting and heat preservation. The intermediate frequency electric furnace is mainly used for smelting carbon steel, alloy steel, special steel, and can also be used for smelting and heating of non-ferrous metals such as copper and aluminum. The equipment is small in size and light in weight. Light, high efficiency, low power consumption, fast melting and heating, easy control of furnace temperature, and high production efficiency.