Intermediate frequency furnace

-

Factory Customized 3T 5T 10T Smelting Electric Furnace

Packaging Details:Wooden case packing

Port:Tianjing

Picture Example:package-img

Lead time:Quantity(sets) 1 – 1 >1

Lead time (days):30 To be negotiated -

Medium Frequency Aluminum Shell Furnace

Smelting process:electromagnetic induction

Applicable site:Factory, plant, etc. -

Casting Intermediate Frequency Furnace

Foundry Intermediate Frequency Furnace is designed and manufactured for the foundry industry scrap metal melting and non-standard medium frequency heating equipment, the use of medium frequency electromagnetic heating principle to quickly melt scrap metal and metal scraps, belongs to the metal remelting category, add trace alloy composition to change the performance index of castings. A, Casting medium frequency furnace profile. 1、Melting metal material: steel, iron, alloy aluminum, alloy co... -

Medium Frequency Melting Electric Furnace

Medium frequency melting electric furnace is often used in the field of some metal material refining, this kind of medium frequency melting electric furnace is very easy to manipulate, the actual operation is very easy, safety, then by everyone and I master the whole process of medium frequency melting electric furnace and the advantages and disadvantages of the detailed introduction it. A, Melting electric furnace Electric furnace melting electromagnetic energy for the heat source of the m... -

Induction Melting Furnace Smelting Equipment

Induction melting furnace is a commonly used heating machine and equipment, the vast majority of smelting plant companies to use this type of melting furnace.

-

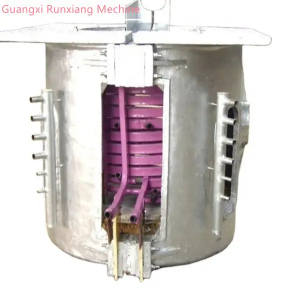

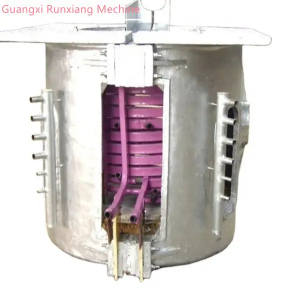

Aluminum Shell Furnace

Product Information: Place Of Origin Guangxi China Power (Kw) 400 Condition Brand New Selling Point Easy To Operate Type Induction Furnace Applicable Industries Manufacturing Plants,Energy And Mining Usage Melting Furnace Product Name Metal Furnace Brand Name Runxiang Application Melting Metal Voltage 380V Features Energy Saving Introduction to the composition of aluminum shell furnace: Aluminum shell intermediate frequency melting furnace is composed of intermediate freque... -

Steel Shell Furnace

The intermediate frequency steel shell furnace body is made of high-quality raw materials and good processing technology, which improves the system efficiency, has stable performance and saves energy. Now it is widely used in the smelting of ferrous metals such as stainless steel, carbon steel and alloy steel, as well as non-ferrous metals such as copper and aluminum, as well as in forging, heat treatment (quenching), welding, pipe bending, metal diathermy, rolling and other processing proces... -

Intermediate Frequency Furnace

The Intermediate frequency furnace is a power supply device that converts power frequency 50HZ alternating current into intermediate frequency (300HZ and above to 1000HZ), converts three-phase power frequency alternating current into direct current after rectification, and then converts direct current into adjustable intermediate frequency current, which is supplied by capacitors. The intermediate frequency alternating current flowing in the induction coil generates high-density magnetic lines of force in the induction coil, and cuts the metal material contained in the induction coil, generating a large eddy current in the metal material.

-

Gas Producer Furnace

A Gas Producer Furnace refers to a reactor used to produce gas, water gas and semi-water gas. The furnace body is cylindrical, the outer shell is made of steel plate or bricks, lined with refractory bricks, and equipped with feeding equipment, blast pipes and gas pipes. According to the structure, it can be divided into mechanical generator, step generator, generator with rotating shaft and two-stage generator. According to the process, it can be divided into fixed bed or fluidized bed gas generator.

-

Induction coil of medium frequency furnace

Induction furnace is an electric furnace that uses the induction electric heating effect of materials to heat or melt materials. The AC power supply used for the induction furnace includes power frequency (50 or 60 Hz), medium frequency (150 ~ 10000 Hz) and high frequency (higher than 10000 Hz). The main components of induction furnace include inductor, furnace body, power supply, capacitor and control system. Under the action of alternating electromagnetic field in the induction furnace, edd... -

Intermediate frequency furnace

Aluminum shell furnace: simple structure. The service life is 5 to 8 years. It is applicable to the capacity of less than 2 tons. There is no guide magnet, furnace lining ejection mechanism, fire-resistant mastic layer, and the safety performance is poor. For example, when a set of 5-ton medium frequency furnace is full of molten iron, the overall weight of the equipment reaches 8 to 10 tons. If the aluminum shell structure is selected and the reducer rotates the furnace body to 95 degrees, t... -

Intermediate frequency induction furnace

The melting power:700KW-8000KW

Smelting time:40 to 90 minutes

The melting temperature:1700

Furnace capacity: 1Ton-12 tons

Product description: A device for converting nonferrous metals into liquids