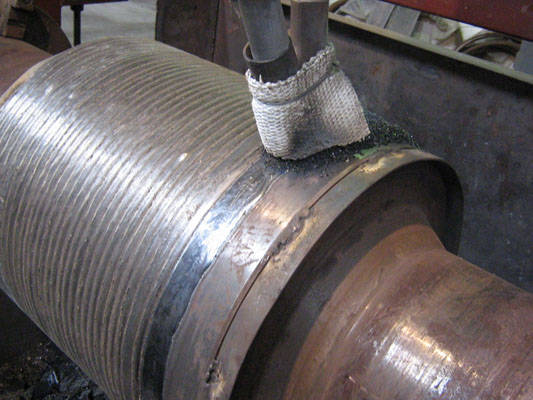

A welding method in which metal is melted by electric or gas welding and deposited on a tool or machine part. It is usually used to repair worn and chipped parts.

Build up welding as an economical and rapid process method for surface modification of materials, resurfacing welding is increasingly used in the manufacture and repair of parts in various industrial sectors. In order to make the most effective use of the overlay layer, it is desired to use an overlay welding method with smaller base material dilution, higher deposition speed and excellent overlay layer performance, i.e. a high quality, high efficiency, low dilution overlay welding technique.

Cold welding overlay technology is the use of high-frequency electric spark discharge principle, the workpiece without heat overlay, to repair the surface defects and wear of metal workpiece, can ensure the integrity of the workpiece; can also use its strengthening function to strengthen the workpiece, to achieve the wear resistance, heat resistance, corrosion resistance, etc.. Cold welding overlay equipment does not deform, anneal, dissolve high strength and resist abrasion to the metal workpiece after repair. It can pass metallographic, tensile and hardness tests, while the metallurgical combination of welding material and substrate ensures the solidity of welding. It is commonly used for repairing pinholes, porosity, burrs, flying edges, bumps, scratches, chipped corners, collapsed corners, grit holes, cracks, abrasions, inclusions, manufacturing errors, manufacturing defects, welding defects and mechanical surface strengthening of precision castings.

Resurfacing welding applications

Mold manufacturing

Plastic mold surface burring to increase aesthetics and service life; helmet plastic mold parting surface overlay repair; aluminum alloy die casting mold parting cone surface strengthening; mold cavity super poor, wear, scratches and other repair and strengthening.

Plastic and rubber

Rubber and plastic machinery parts repair, rubber, plastic parts with mold overlap, wear and repair.

Aerospace

Aircraft engine parts, turbine, turbine shaft repair or repair, rocket nozzle surface strengthening repair, aircraft outer plate parts repair, artificial satellite shell strengthening or repair, titanium alloy parts of local carburization strengthening, iron-based high-temperature alloy parts of local carburization strengthening, magnesium alloy surface carburization A1 and other anti-corrosion coating, magnesium alloy parts of local defects overlay repair, nickel-based / cobalt-based high-temperature alloy blade workpiece local overlay repair, such as : blade crown damping surface and the tip of the blade wear and guide blade ablation, etc.

Manufacturing repair

Automobile manufacturing and maintenance industry, used for cam, crankshaft, piston, cylinder, brake disc, impeller, wheel hub, clutch, friction plate, exhaust valve, etc. to make up the difference and repair, the surface of the car body weld defect repair.

Ship power

Electric crankshaft, bushings, shaft tiles, electrical components, resistors, etc. repair, welding of electric railroad wheels and bottom line rail connection piece, electroplating plant conductive roller, metal oxidation treatment of copper and aluminum electrode production welding.

Machinery industry

Build up welding can correct the workpiece with excessive difference and repair machine tool guide, various shafts, cams, hydraulic press, hydraulic press plungers, cylinder walls, journals, rollers, gears, pulleys, arbors for spring forming, plug gauges, ring gauges, various rolls, rods, columns, locks, bearings, etc.

Casting industry

Repair of defects such as sand holes and air holes in iron, copper and aluminum castings, and repair of wear and tear of aluminum models.

Post time: Nov-03-2022