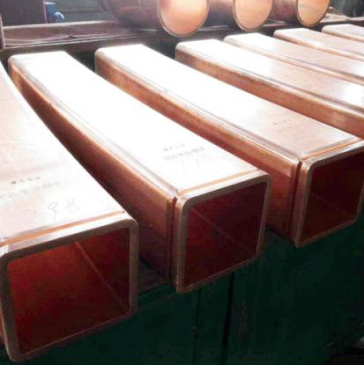

Depending on the billet cross-section, they are generally divided into

Square billets (rectangular billets): small square billets, large square billets

Round billets: small round billets, large round billets, hollow rounds

Slabs: small slabs (flat slabs), regular slabs, wide and thick slabs, thin slabs

Shaped billets: I-beam, U-beam

Thin strip: double roll continuous casting

1) Ladle rotary table

The ladle rotary table is used to rotate the ladle to or out of the pouring position, mainly straight arm type and butterfly type.

2)Intermediate tanker

The intermediate tank car carries the intermediate tank filled with steel and travels between the set pouring position and baking position to realize the lifting, centering and weighing function of the intermediate tank.

The crystallizer makes the steel poured into it cool quickly and condense and form initially according to the required section. Ensure that the steel billet shell out of the crystallizer can withstand the internal static pressure of the unconsolidated steel.

4) Crystallizer vibration device

To keep the relative movement between the crystallizer copper tube and the billet solidification shell, so that the two maintain a good state of demoulding and cooling heat transfer effect. Mainly mechanical, hydraulic and electric cylinder vibration is more widely used.

5) Fan-shaped section (guide section)

The cast billet with liquid core comes out of the crystallizer into the fan section (guide section) and is gradually solidified by the support and guidance of the rollers in the fan section (guide section).

It is used to convey the lead rod, to pull out the lead rod and the hot billet from the crystallizer, and to straighten the hot billet according to the minimum critical stress. The cast billet enters the horizontal section and is completed by the fire cutter or hydraulic shear for cut-to-length cutting, and then transported by the post-cut roller conveyor to the outgoing billet roller conveyor.

6) Pulling and straightening machine

It is used to transport the ingot rod, pull out the ingot rod and hot billet from the crystallizer and straighten the hot billet according to the minimum critical stress. The billet enters the horizontal section and is cut to size by a fire cutter or hydraulic shear, and then transported by the post-cut roller conveyor to the exit roller conveyor.

Post time: Jan-19-2023