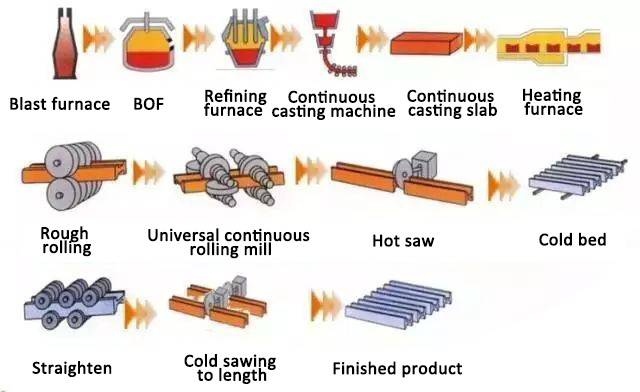

Generally, small and medium-sized (H400×200 and below) H-beams mostly use square billets and rectangular billets, and larger-sized (H400×200 and above) H-beams mostly use special-shaped billets, and continuous casting billets can be used for both rectangular and special-shaped billets. After being weighed, the billet from continuous casting is loaded into a step-by-step (or pusher type, there are relatively few pusher furnaces used to produce section steel) heating furnace and heated to 1200-1250°C to be released from the furnace. Most of the walking heating furnaces adopt double preheating burners arranged up and down, which can provide the best temperature control for billets of different specifications and save fuel.

After the billet comes out of the furnace, it is first descaled with 10-25MPa high-pressure water, and then sent to the billet mill for rolling. The blanking machine is generally a two-roll reversible rolling mill (there is also a three-roll rolling mill for small steel, but the process limitation is not conducive to the production organization), and the blanking machine needs to be rolled for about 5 to 13 passes, and then the rolled piece The hot saw is only responsible for cutting off the unformed part of the head, but the flying shear can cut the head, segment and tail. The rolled pieces after head cutting are sent to the finishing rolling mill for rolling. The finishing rolling of small-sized section steel of major domestic manufacturers adopts the form of continuous rolling, and the finishing rolling of large-size section steel is reversible rolling. After finishing rolling, it is generally sent directly to the cooling bed for cooling, but there are also sections that are segmented before the cooling bed or cut after the cooling bed. Due to the relatively large difference between the thickness of the legs and the thickness of the waist of large-sized section steel, if it is placed flat, the cooling speed of the waist and legs is inconsistent, causing waves at the waist, so vertical cooling is generally used. However, the mainstream manufacturers of small-sized H-beams all adopt stepping tooth cooling beds, which are placed obliquely on the rack. Using stepping tooth cooling beds can not only reduce the defects caused by the original chain hauling mechanism, but also easily control the cooling of steel speed. The cooled H-beam is sent to the straightening machine for straightening. Due to the large section modulus of H-beams, 8-roll, 9-roll or 10-roll straightening machines are generally used for straightening, and the maximum distance between straightening rollers can reach 2200mm. After being straightened, the steel is sent to the marshalling stand for grouping and waiting for sawing. After being cut by a cold saw according to a fixed length, it is sent to the inspection table to check the size, shape and surface quality, and then sorted, stacked and bundled. sent to the warehouse. For unqualified products, according to the type of defect, corresponding re-straightening, grinding, welding repair and other treatments will be carried out, and then they will enter the corresponding quality inspection program and then be classified into storage after passing the inspection.

In order to improve the operating rate of the rolling mill and reduce the roll changing time, almost all manufacturers adopt a quick roll changing system, that is, the rolls required for the next variety are assembled in advance while producing. When changing rolls, just pull out all the original racks and replace them with new racks that have been installed. Each frame is equipped with a quick connector panel, which includes cooling water, hydraulic pressure, thin oil and dry oil pipe joints and positioning connection devices for connecting rods. The device is easy and fast to disassemble and connect, and the entire roll changing time is about 10-20 minutes. According to the roll changing experience of small steel, the overall roll changing time is generally about 45-70 minutes.

Post time: Feb-20-2023