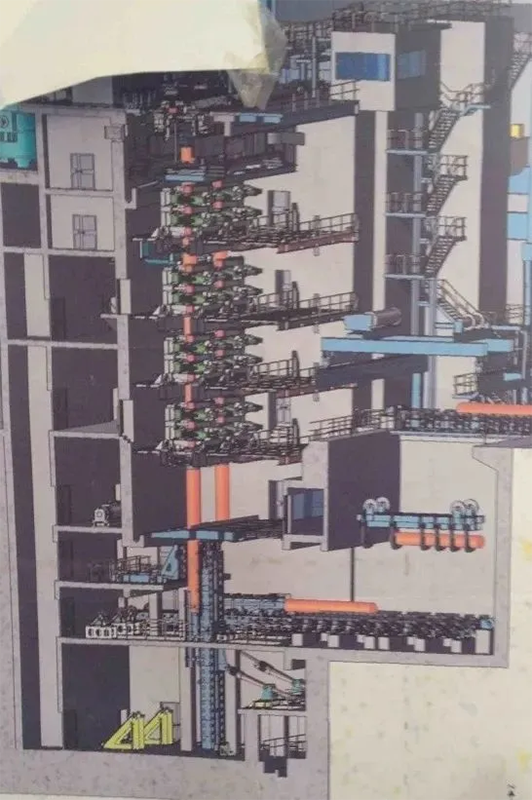

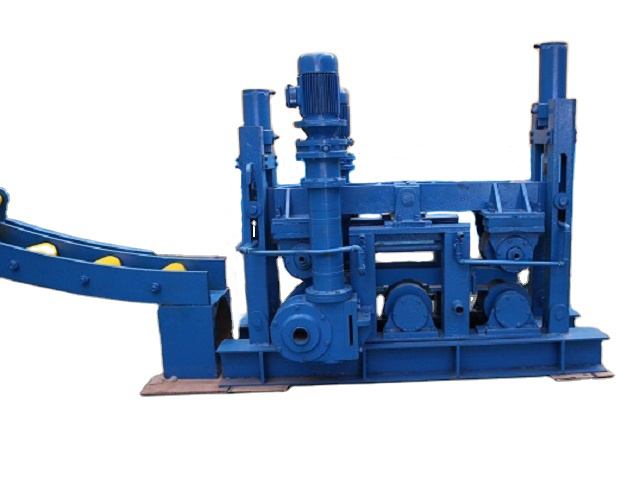

Continuous casting is a revolutionary process used in the manufacturing industry to produce metal products such as copper, aluminum and steel of exceptional quality and consistency. The continuous casting machine (CCM) is a key piece of equipment in this process. It is an advanced automated industrial machine that transforms raw materials into semi-finished products with excellent dimensions and surface quality.

So how does the continuous casting machine work? The continuous casting machine process goes through five key stages. First, raw materials such as copper, aluminum or steel are placed on a continuous casting machine. Guangxi Runxiang Machinery is a leading supplier of continuous casting machines with a production area of 20,000 square meters. The raw material is then melted in the machine and heated to a temperature above its melting point.

Next, the pouring liquid is poured into the casting mold of the continuous casting machine, which is usually in the shape of a long strip. This process, called pouring, is the third stage. The temperature of the pouring liquid plays a crucial role in its fluidity during the pouring process. Slight changes in temperature can have a major impact on the final product.

The stage after pouring is cooling. The liquid metal in the mold begins to cool and solidify until it hardens into a long billet. The cooling process relies on cooling water passing through spray pipes around the machine to cool the mold and strip as it emerges.

The final step in the continuous caster process is cutting. Long steel billets are cut to precise dimensions by high-precision automated machines. With modern technology, these machines optimize production output, minimize production waste and achieve maximum efficiency.

Continuous casters are ideally suited for today’s fast-paced manufacturing processes, where reliable, high-quality products need to be delivered in short periods of time. They have become a game-changing technology in the industry, replacing traditional casting methods. An important aspect that sets continuous casters apart is their ability to ensure products of consistent quality and size.

Guangxi Runxiang Machinery is a metallurgical machinery enterprise embodying innovation and excellence. Founded in 2015, the factory covers an area of 10,000 square meters and has more than 50 employees, including 5 core scientific researchers and 3 engineers. They offer a full line of continuous casters to meet the unique needs of their customers. Guangxi Runxiang has made significant contributions to the manufacturing industry, and its products have had a positive impact on countless economic fields.

In conclusion, continuous casting machines are one of the most innovative and efficient methods of producing high-quality metal products. The continuous casting machine process includes melting, pouring, cooling and cutting. The capabilities offered by Guangxi Runxiang Machinery ensure you receive reliable products and excellent quality control. Investing in a continuous caster is a smart move for an industry that values quality, efficiency and timeliness.

Post time: Apr-03-2023