1.The steel rolling mill needs to check the tightness of the hot feed rollers, inlet rollers base foot bolts, side guide plate fixing bolts and other connecting bolts every day, and if there is any loosening, it should be dealt with in time.

2.Check the lubrication condition of roller bearing seat and water-cooled water supply and drainage condition of roller bearing seat regularly, once a month.

3.Check the wear, cracks and hair pulling condition of the surface of the roller conveyor body once a week.

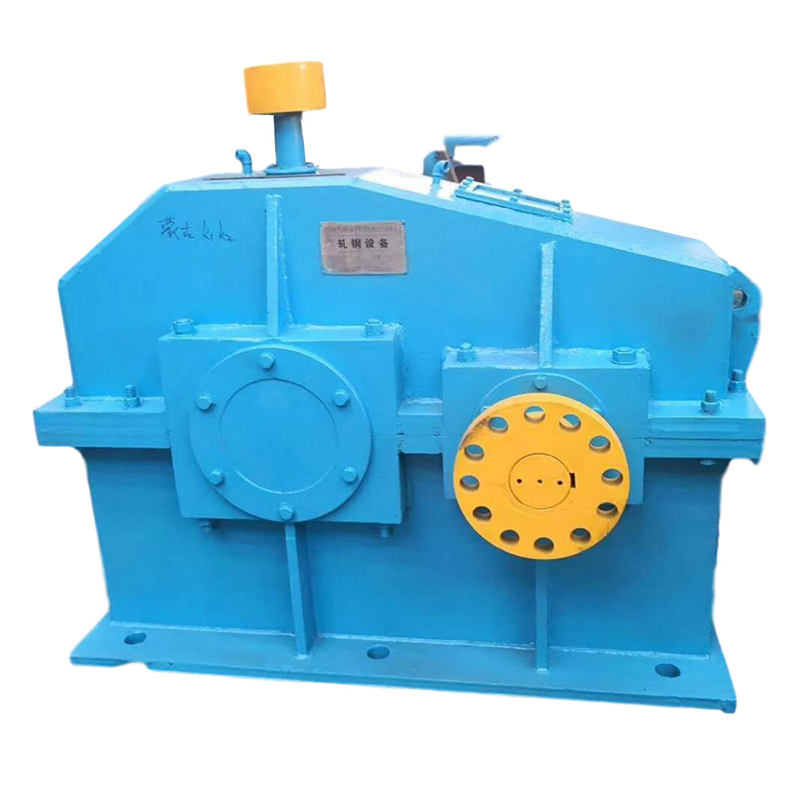

4.The gear box of reducer motor should be opened once every 6 months to check the gear wear and replace the lubricant, and the seal of gear box should also be replaced regularly.

5.Sweep the iron oxide under the hot feed roller conveyor, lifting table and furnace roller conveyor once a week.

6.Check the wear of the coupling of the hot feed roller conveyor and the furnace roller conveyor once every 3 months.

7.Check daily whether the foot bolt of the base of the steel pushing machine is loose; whether the steel pushing rod is deformed; whether the hydraulic cylinder should work sensitively and reliably without oil leakage, whether the hydraulic cylinder is synchronized and whether there is oil leakage, and if problems are found, deal with them in time.

8.Check daily whether the base bolts of the steel pushing machine are loose; the hydraulic cylinder should work reliably and without oil leakage, whether the hydraulic cylinder is synchronized, and whether there is oil leakage; whether the steel pushing trolley is running normally.

9.No loose connection bolts of the lifting table; normal movement of the reducer without noise, the oil level should not be lower than the lower limit of the oil mark; check the chain and sprocket to ensure smooth transmission, the chain is suitable for the degree of tightness, and often lubricate the chain.

10.Whether the flat pallet device is running smoothly, there is no shaking phenomenon, if the above problems should be promptly contacted the pincers to replace the paddle device; regular oil lubrication of the small shaft of the flat pallet device, once a week;

11.Is the cold billet table frame paddle claw damaged, is the rail pressure plate bolt tight, the hydraulic cylinder should work sensitive and reliable and no oil leakage, the hydraulic cylinder is synchronized, there is no oil leakage.

Post time: Mar-08-2023