For the daily operation of enterprises, machinery and equipment play an important role, only when the machinery and equipment running stable, to create good economic benefits for enterprises. In the rolling mill, the rolling mill plays a key role, but if there are problems with equipment lubrication, it will affect the normal operation of the rolling mill machine. Relevant research and practice shows that after the steel rolling equipment in the factory, its service life depends largely on the lubrication work carried out well, abnormal wear caused about 80% of the parts damage, bad lubrication led to 60% of the equipment failure. In the machinery industry, due to poor lubrication increased equipment costs in the total cost of the proportion of up to 30%. The proportion of bearing failure caused by poor lubrication surprisingly occupies 54% of the total number of bearing failures. It can be seen, lubrication failure on the one hand, the mechanical equipment itself caused damage; on the other hand, also hindered the normal operation of the production line, to the enterprise economic benefits brought about by the negative impact. Therefore, the lubrication condition of the steel rolling equipment management has become imperative.

Rolling mill machine requirements for lubrication

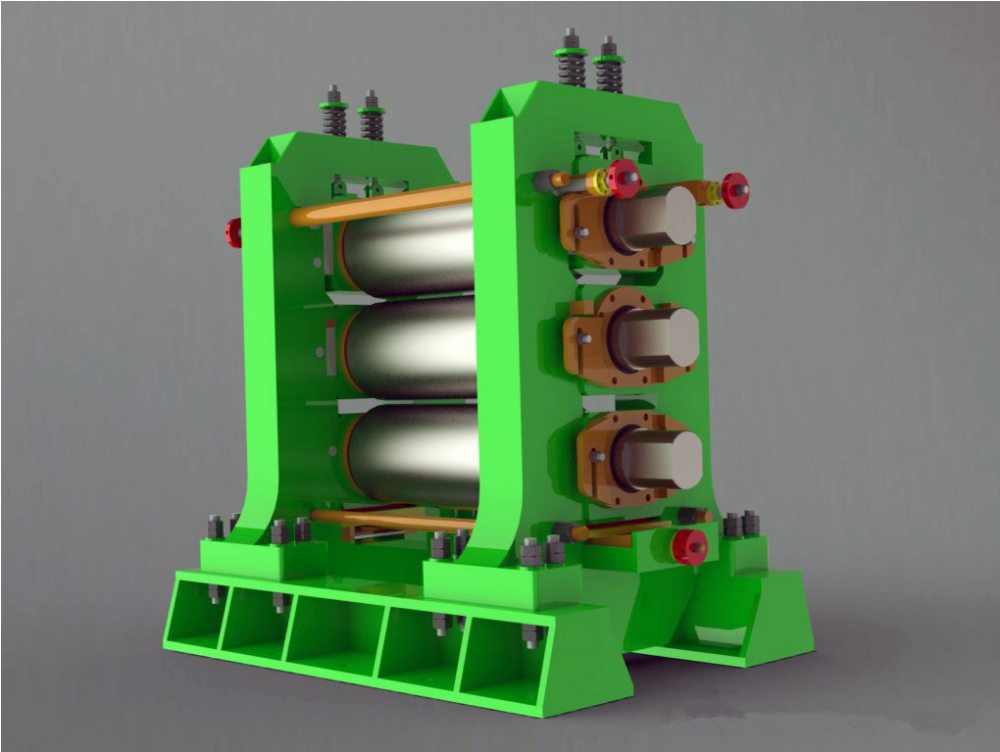

Steel rolling mill components mainly include the motor, main coupling, front and rear coiling machine. The following requirements are made for lubrication: first, thin oil lubrication; second, dry oil lubrication; third, high speed and high precision rolling mill bearings using oil and gas and oil mist lubrication.

During the rolling steel, in order to enhance product quality and improve the elongation of the rolled material, the process lubrication and cooling substances need to be added between the rolls and the rolled material. Generally speaking, the rolling mill requires process lubrication and cooling media with the following characteristics: first, good cooling capacity; second, lower cost, easy access to oil sources; third, appropriate oil; fourth, can achieve the rolls and products surface flushing and cleaning; fifth, better filtration; sixth, good annealing properties for cold-rolled strip; seventh, oxidation resistance, physical and chemical stability and rust resistance; eighth, not It is not harmful to human health.

Post time: Oct-21-2022