The size of the rolling mill is related to the size of the product. The rolling mills such as billet and section steel are represented by the diameter of the roll, while the length of the steel plate mill is represented by the length of the roll body, and the steel tube mill is represented by the maximum outer diameter of the steel pipe it is rolling.

1.Billeting mill A rolling mill that uses steel ingots as raw materials to provide raw materials for finished rolling mills, including billet blooming mills, billet blooming mills, and slab blooming mills.

2.Billet rolling mill It is also a rolling mill that provides raw materials for finished rolling mills, but the raw materials are not steel ingots, generally divided into two types: continuous and horizontal.

3.Section steel rolling mills include rail beams, large, medium and small rolling mills and wire rod rolling mills.

4.Hot rolled strip mills include thick plate mills, wide-band mills, and stacked sheet mills.

5.Cold-rolled sheet and strip rolling mills include sheet-made cold-rolling mills for steel sheets, wide-band cold-rolling mills for coil production, and narrow-strip cold-rolling mills for coil production.

6.Steel pipe mills include hot-rolled seamless steel pipe mills, cold-rolled steel pipe mills, welded pipe mills,

7.Special-purpose rolling mills include wheel rolling mills, ring-hub rolling mills, steel ball rolling mills, periodic section rolling mills, gear rolling mills, and lead screw rolling mills.

It can be seen that the above classification method is basically classified according to the cross-sectional shape of the rolling mill products.

The composition of rolling machinery equipment can be divided into two categories: main equipment and auxiliary equipment.

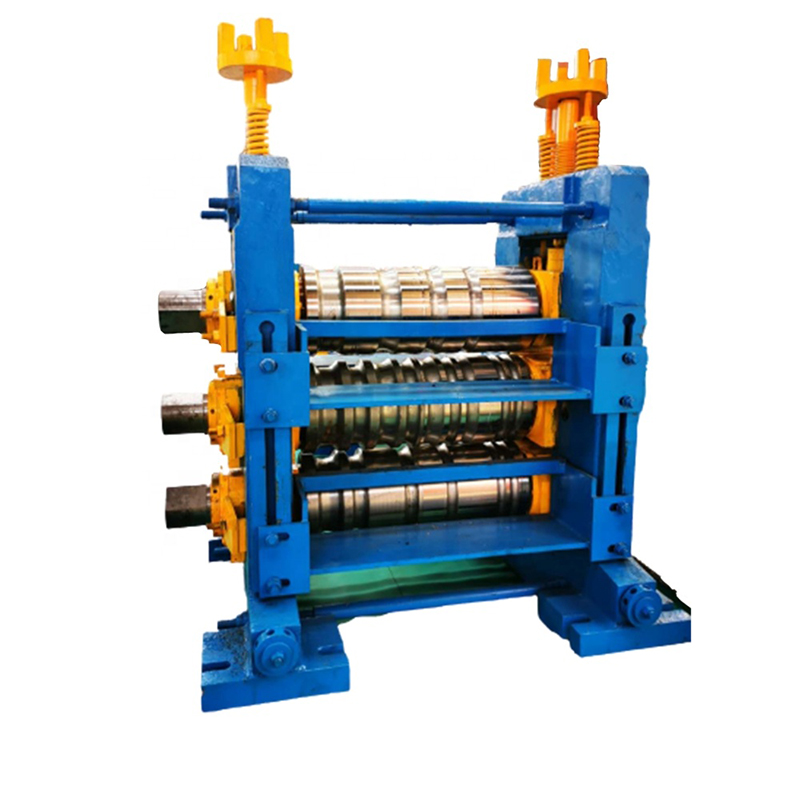

1. Main equipment: The equipment that directly causes the plastic deformation of the rolled piece is called the main equipment, and it is also the main machine. It includes: working stand (roll, bearing, roll adjustment device, guide device and frame, etc.), universal or plum blossom joint shaft, gear stand, reducer, main coupling, main motor, etc.

2. Auxiliary equipment: refers to various equipment other than the host column, which is used to complete a series of auxiliary processes. It includes shearing equipment, roller table, coiler, straightener, etc. There are many kinds of auxiliary equipment, and the workshop is highly mechanized, and the proportion of auxiliary equipment in the total weight of the entire workshop equipment is also larger.

Post time: Aug-31-2022