Industry News

-

The Importance Of Dust Collectors In Metal Smelting Equipment

When it comes to metal smelting equipment, dust collectors cannot be ignored. These industrial dust collectors play a vital role in maintaining a safe and efficient production process. Runxiang Machinery is well aware of the importance of providing complete sets of equipment and accessories for m...Read more -

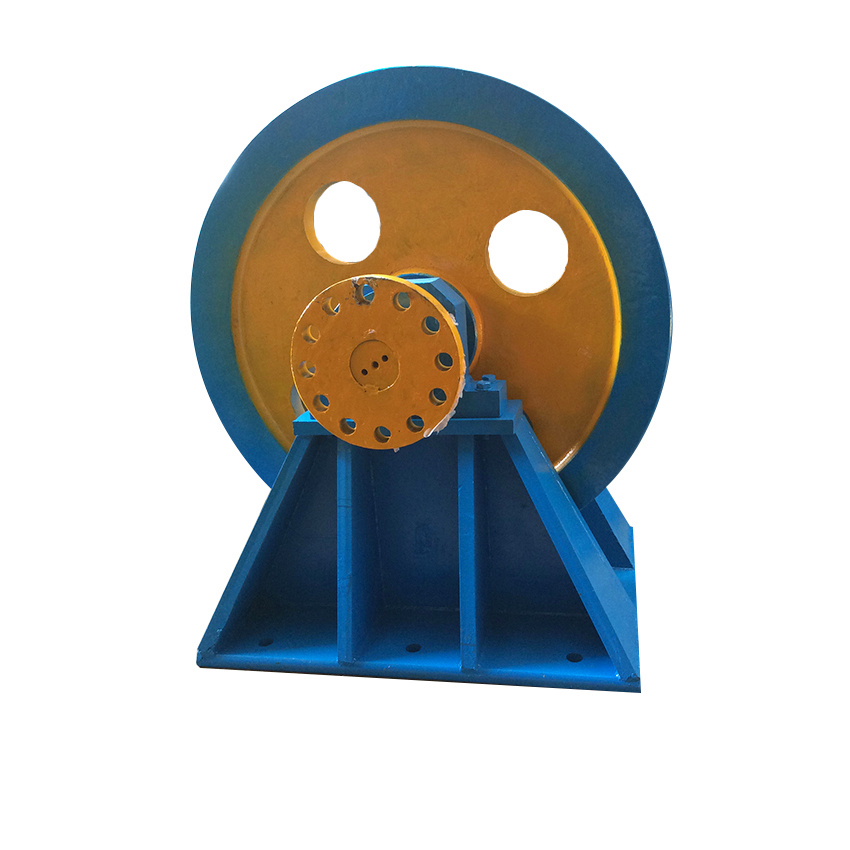

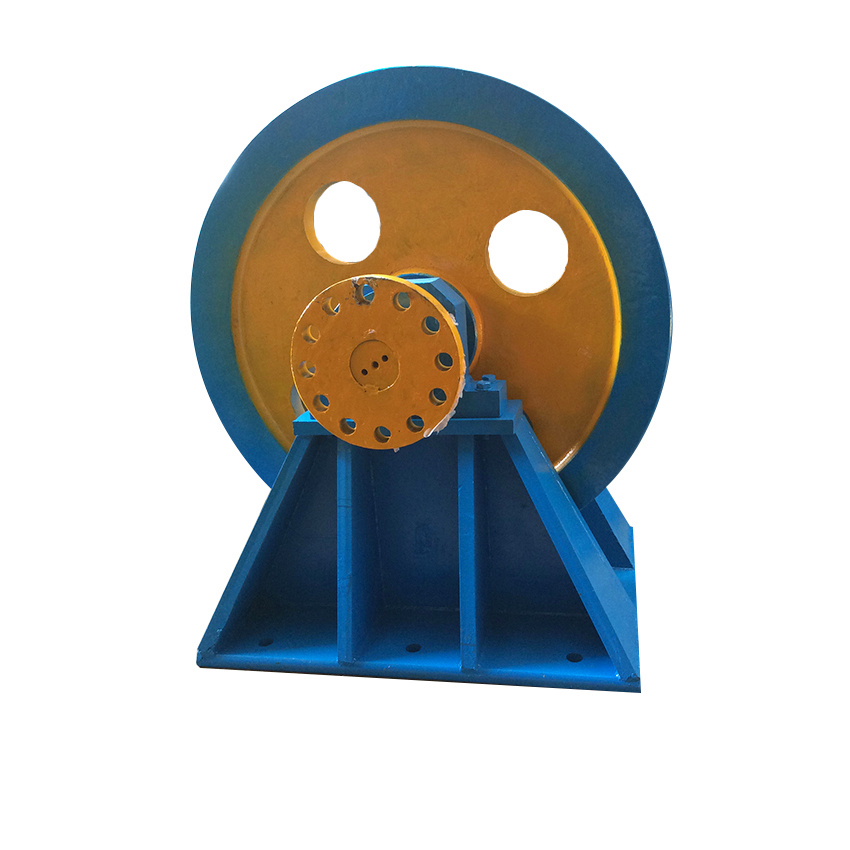

Fly Wheel: An Essential Component In Rolling Mill Equipment

In industrial manufacturing, rolling mills play a vital role in the production of high-quality steel bars. These factories require custom industrial equipment that can handle extreme pressure and heat to form metal into the desired shape and size. For these machines to run efficiently and effecti...Read more -

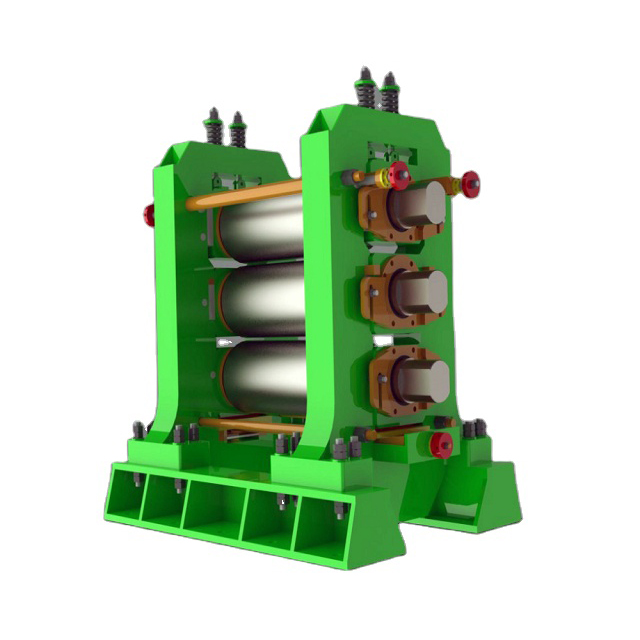

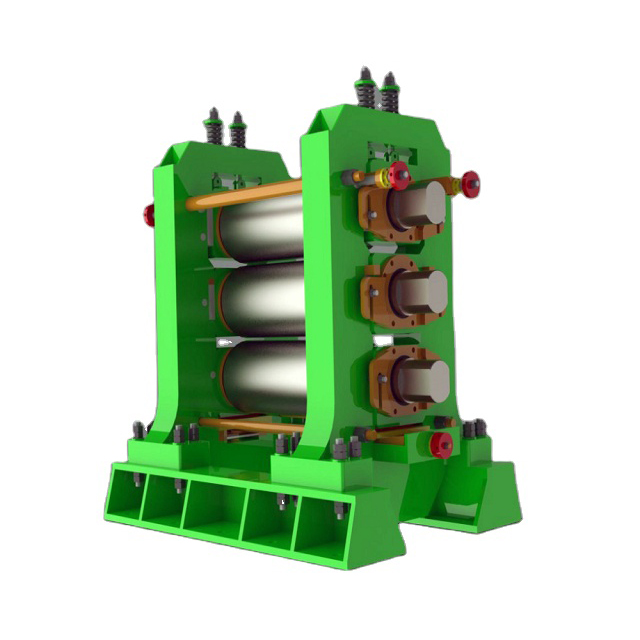

Back Up Roll Mills: Provide Maximum Support And Stability For Workpieces

Backup rolls are an important part of rolling mills used in the metallurgical and steel industries. Their main role is to provide support and stability to the workpiece during rolling, ensuring smooth and efficient operation. At Runxiang Machinery, we understand the critical role backup rolls pla...Read more -

The Importance Of High Speed Flying Shears

Flying shears are indispensable equipment in steel rolling equipment and play a vital role in the metal processing industry. In particular, high speed flying shears are highly sought after for their ability to quickly cut through iron plates, steel pipes and paper rolls. These shears are an indis...Read more -

Why Steel Shell Furnace Is So Popular

Steel shell furnace, also known as intermediate frequency furnace, is an advanced metal smelting equipment, which is highly sought after by all walks of life for its excellent performance and performance. Guangxi Runxiang Machinery is a well-known manufacturer of these furnaces with extensive exp...Read more -

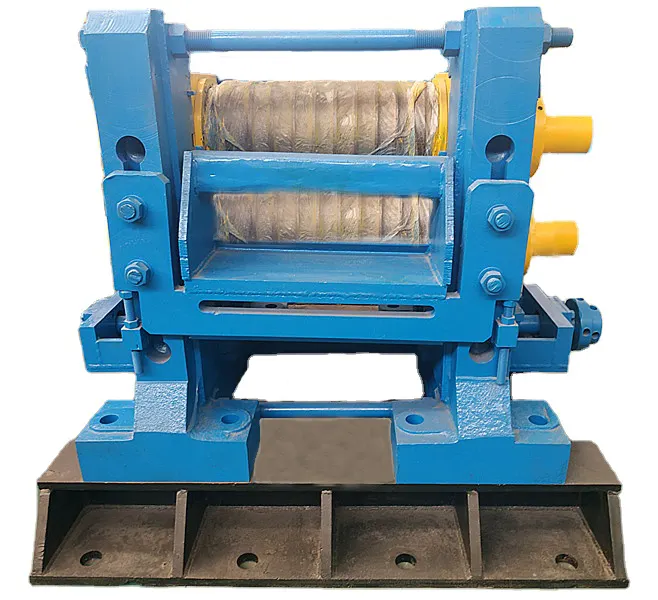

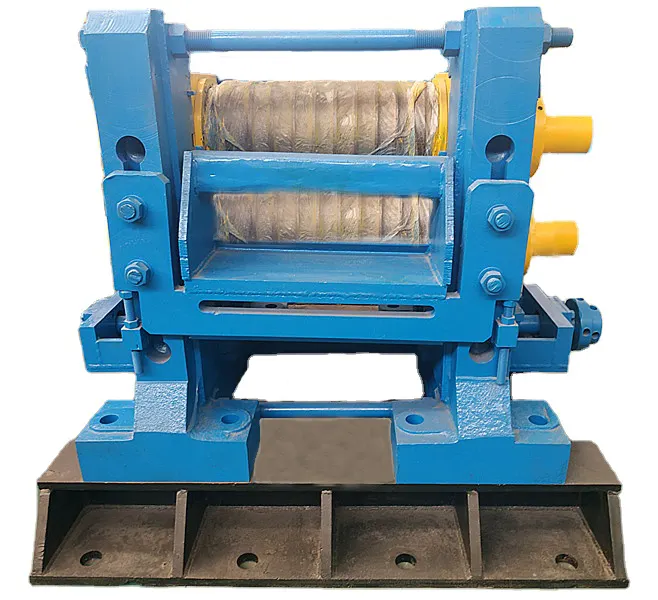

The Importance Of Flat Wire Rolling Machine

The short stress line rolling mill has become an important tool in the steel industry. They have high stiffness rolling capabilities and are used as shapes in a variety of applications. Runxiang Machinery is a leading rolling mill manufacturer in China with many years of industry experience. Flat...Read more -

Revolutionizing Steel Production: Automatic Cooling Bed For Steel Rolling Mill

In today’s competitive world, every industry is striving to be more efficient and effective. One industry that is constantly evolving and looking for innovative solutions is the steelmaking industry. In order to meet the ever-increasing demands of consumers, it is very important to efficien...Read more -

Three High Mill: The Backbone Of Steel Production

Runxiang Machinery is a leading manufacturer of rolling mill equipment for steel production. Our product range includes roughing mill, back up mill and three high rolling mill, among others. Our equipment can produce all kinds of steel products, such as bars, wires, strips and so on. With an annu...Read more -

The Importance Of Aluminum Melting Furnace Suppliers To Intermediate Frequency Furnace Factory

With the increasing demand for metals in various industries, intermediate frequency furnace factory have become more important than ever. These factories are responsible for the production of high-quality metals for everything from automobiles to construction. However, their efficiency and output...Read more -

Understanding The Characteristics Of Short Stress High Stiffness Rolling Mill

Rolling mills are crucial in the manufacturing industry as they play a vital role in shaping and transforming metals into the desired products for various applications. Among these mills, the short stress line mill stands out for its high stiffness and robust mechanical structures that allow for ...Read more -

Working Principle Of Hot Rolling Mill

The working principle of a hot rolling mill is a complex process that involves the gradual reduction of the mirror wheel track using advanced steel rolling equipment. This process culminates in rough iron being rolled and extruded into a variety of strong metal shapes, including square bars, angl...Read more -

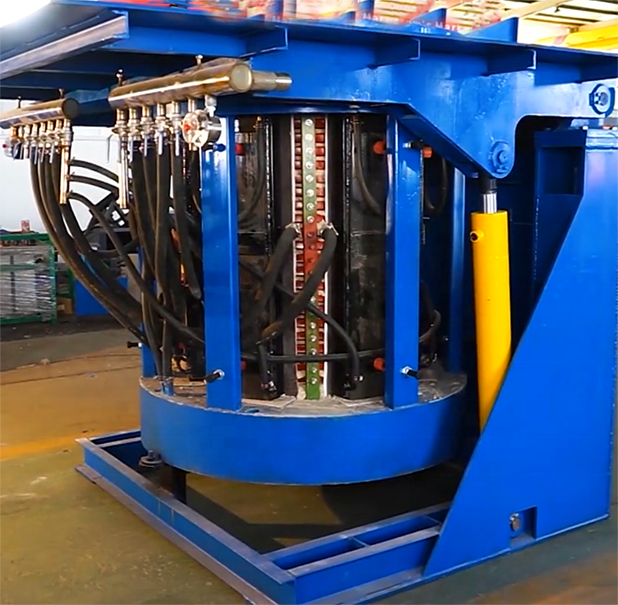

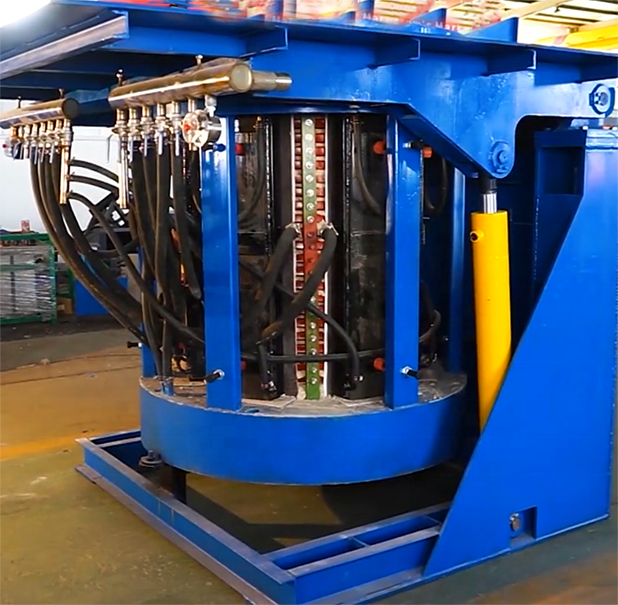

Induction Furnace Coil Design: The Heart of an Induction Furnaces

As the technology for heating and melting metals continues to develop, the use of induction furnaces is becoming more and more popular in various industries. One of the key components of an induction furnace is the induction furnace coil, which is responsible for the actual heating and melting of...Read more