rolling mill

-

Rolling Mill Equipment Plate Mill Machine

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Continuous Rolling Two Roll Mill

Packaging Details:Wooden case packing

Port:Tianjing

Lead time:

Quantity(sets) 1 – 1 >1 -

Tandem Cold Rolling Mill

Packaging Details:Wooden case packing

Port:Tianjing

Lead time:

Quantity(sets) 1 – 1 >1

Lead time (days) 30 To be negotiated -

Backup Rolls Rolling Mill

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Steel Plate Rolling Mill – Custom Industrial Equipment

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Aluminum Casting And Rolling Mill

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Universal Rolling Mill-Custom Industrial Equipment

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Vertical Mill For Sale

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

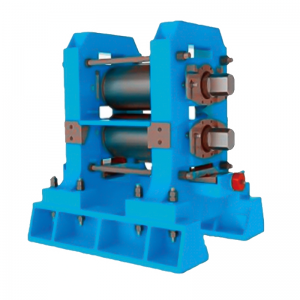

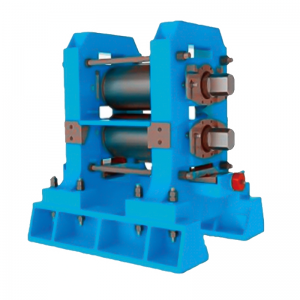

Industrial Equipment Four Roller Mill

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

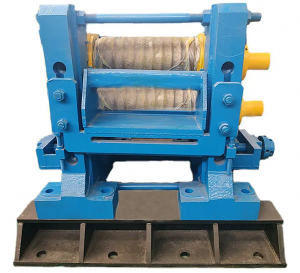

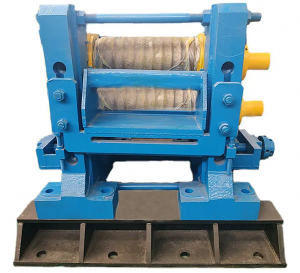

Two Roll Mill Steel Rolling Equipment

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

No Twist Wire Rod Mill Equipment

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.

-

Hot Rolled Deformed Bar Making Machine

PACKAGE AND TRANSPORT

PACKAGING:Shrink film,wooden box,container

TOTAL WEIGHT OF GOODS:Not more than 25 tons

DELIVERY DETAILS:We will provide you with fast and stable delivery service.