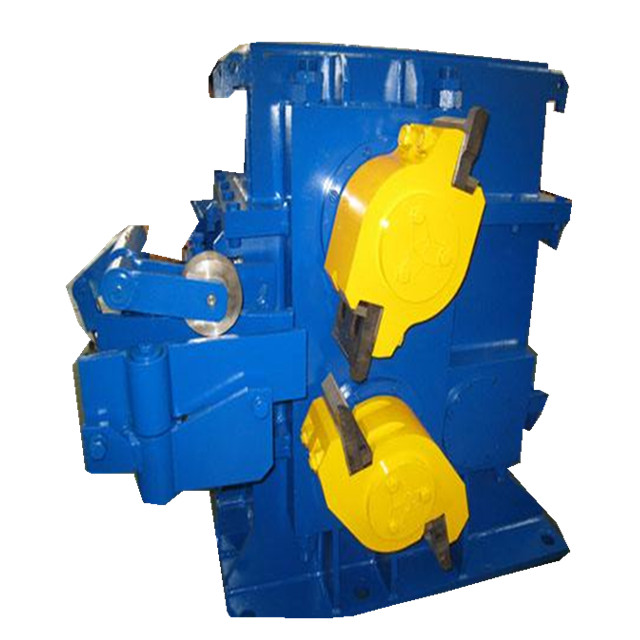

Rotational Flying Shears

Product information:

Work requirements:

The cut-to-length flying shears should ensure good cutting quality-accurate cut-to-length, neat cut surfaces, and a wide range of cut-to-length adjustment, as well as a certain shearing speed. In order to meet the above requirements, the structure and performance of the flying shear must meet the following requirements during the shearing process:

1. The horizontal speed of the shearing edge should be equal to or slightly greater than the movement speed of the rolling piece;

2. The two cutting edges should have the best cutting edge clearance;

3. During the shearing process, the cutting edge should preferably move in plane translation, that is, the cutting edge is perpendicular to the surface of the rolling piece;

4. The flying shears must work according to a certain working system to ensure the fixed length;

5. The acceleration and mass of the moving components of the flying shear should be minimized to reduce inertial force and dynamic load.

Rotational flying shears are often used in steel rolling, papermaking and other production lines. In continuous rolling billet workshops or small section steel workshops, it is placed at the back of the rolling line, and the rolling stock is cut to length or only the head and tail are cut. There are various types of flying shears in the transverse shearing unit, heavy shearing unit, galvanizing unit and tinning unit in cold and hot steel workshops, which cut strip steel into fixed lengths or steel coils of specified weight. The widespread use of flying shears is conducive to the rapid development of steel rolling production in the direction of high speed and continuity. Therefore, it is one of the important links in the development of rolling steel production.