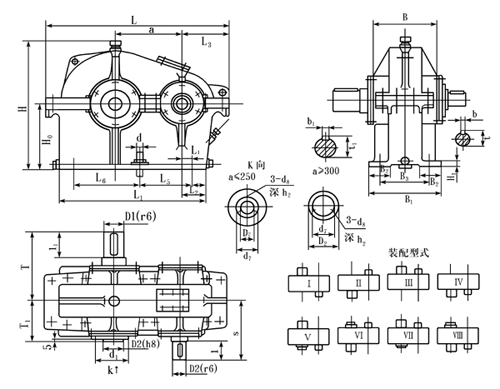

Transmission Gearbox Speed Reducer

Feature:

1. Advanced grinding technology is used for secondary processing to make the surface of the reducer smoother, more stable and durable.

2. Long service life and high efficiency. Reasonable design to ensure smooth operation of the reducer, low dryness and multiple precision machining.

3. High output, low noise.

ZD Speed Reducer is a single-stage involute cylindrical gear reducer, ZDH is a single-stage circular circular cylindrical gear reducer, ZDSH is a single-stage double-circular cylindrical gear reducer.

They are mainly used for mechanical transmission of mining, metallurgy, cement, construction, chemical industry, secret service and other mechanical equipment. The high-speed shaft speed is not more than 1500r/min, and the gear circular speed is not more than 18m/s. The working environment is -40℃ ~ +40℃.

Mark code of ZD reducer

The marks of ZD, ZDH and ZDSH reducer include: model, center distance, transmission ratio, assembly type, etc.

Marking code:

ZD, ZDH, ZDSH single stage cylindrical gear reducer installation dimensions

The company’s production equipment is mainly used in rolling mills, the equipment can produce bar, wire, steel, strip steel, output from 10,000 tons/year to 500,000 tons/year:

Company Profile

Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd. was established in May 2021. It is a national high-tech enterprise specializing in R&D, manufacturing, sales and service of steel rolling production line equipment. At present, it has production supporting processes such as steelmaking, cast steel, heat treatment, mechanical processing, and surfacing welding, forming an integrated industrial chain of smelting, casting, metal heat treatment, and mechanical processing. The main equipment includes: 3 intermediate frequency furnaces, 1 centrifuge, 1 holding furnace, 1 heat treatment furnace, 1 spectrum analyzer; more than 30 various milling, boring, horizontal, and surfacing lathes and advanced testing and inspection equipment . Mainly provide complete sets of equipment and accessories for metallurgy, steel rolling, mine and other industries. Products are exported to Southeast Asia, the Middle East, Central Asia, Europe and other countries and regions.