PlasmaHaha Welding, joalo ka e 'ngoe ea mahlale a matlafatsang holim'a metsi, e na le melemo ea ho hlahisa lisebelisoa tse fapaneng tsa phofo ea alloy, lera le letenya, le hlapollang le tlase, tlhahiso e phahameng ea tlhahiso, tšebeliso e tlase ea lisebelisoa tsa alloy le theko e tlase.Bokaholimo ba eona ha bo na kutu, ha bo mamelle, Ntlafatso ea ho hanyetsa mocheso o phahameng e hohetse tlhokomelo e eketsehileng.

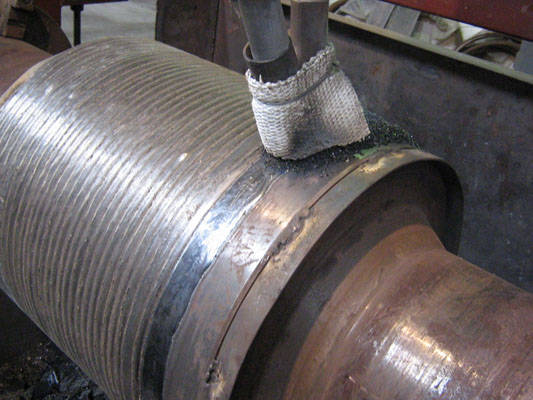

Hona joale, li-powders tsa alloy tse thehiloeng ka tšepe, nickel le cobalt li sebelisoa haholo bakeng sa plasma.buildup welding.Phofo e entsoeng ka tšepe e nang le tšepe e na le khanyetso e ntle ea ho apara le theko e tlaase, empa e hanyetsa mocheso o fokolang le ho hanyetsa ho bola.Li-powders tsa alloy tse thehiloeng ho nickel le cobalt li na le khanyetso e ntle ea kutu le ts'ebetso e phahameng ea mocheso, empa litšenyehelo li batla li le holimo.Ho sebelisa plasma arc ho beha phofshoana e entsoeng ka tšepe e ikemetseng, phofo ea nickel-based self-fluxing alloy le nickel-based alloy hammoho le wc composite phofo holim'a tšepe ea 16mn, ka liteko tsa ho apara mecheng e fapaneng ea ho senya, liphello tsa tse tharo. mefuta e meng ea likarolo tse holimo e ile ea ithutoa Microstructure, sebopeho sa mekhahlelo, ho thatafala le ho hanyetsa ho roala.

Tšusumetso ea liphatlalatso tse fapaneng tse senyang holim'a ho hanyetsa ha lesela le tšoanang la alloy surfacing le tsona li fapane.Ho hanyetsa ha lesela le okametseng sebakeng se nang le metsi a sa jeleng paate ho molemo ho feta sebakeng sa asiti le alkaline.Sena se bakoa haholo ke hore seaparo se le seng se sebetsa metsing.Ka tharollo ea HCl e hlapollang le ho hlapolla tharollo ea NaOH, betri e nyenyane e hlahisoa pakeng tsa motsoako le tharollo e tiileng, 'me ho na le tšebelisano pakeng tsa ho roala le electrochemical corrosion, e le hore lera le ka holimo le be ka har'a tharollo ea HCl e hlapollang.'Me ho hanyetsa ho roala ka har'a dilute NaOH tharollo medium e fokotsehile ka lebaka la tšusumetso ea ho hanyetsa kutu.

Ha ho bapisoa le ho hanyetsa ha lesela le ka holimo ka ho hlapolla HCl le ho hlapolla NaOH medium, ho fumanoa hore ho hanyetsa ho roala ka har'a HCl medium ho fokola, hobane lera le ka holimo le ka etsa filimi ea passivation ka ho hlapolla HCl le ho hlapolla NaOH medium, Leha ho le joalo, passivation filimi e hlapollang HCl e bonolo ho senyeha, 'me filimi ea passivation ka ho hlapolla NaOH medium ha e senyehe habonolo, kahoo ho hanyetsa ha lesela le holimo ka ho hlapolla NaOH medium ho molemo ho feta ho hlapolla HCl acid..

Ho thatafala ha lera le holimo la Ni60 le tšoana le la Fe55.Ho hanyetsa ho roala ha lera la Ni60 ka holim'a tharollo ea hydrochloric acid le ho hlapolla tharollo ea NaOH ho molemo ho feta ea Fe55, empa se fapaneng ke 'nete metsing a sa nke lehlakore.Bakeng sa lera le holimo la motsoako o tšoanang, ho hanyetsa sebakeng se senyang sa HCl tharollo le ho hlapolla tharollo ea NaOH e tlase ho feta metsing a sa jeleng paate, 'me phokotso e bonahala haholoanyane mobung o nang le asiti.

Nako ea poso: Feb-14-2023