Casting Intermediate Frequency Rauv

FoundryIntermediate Frequency Rauv yog tsim thiab tsim rau kev lag luam foundry scrap hlau melting thiab tsis yog-tus qauv nruab nrab zaus cua sov cov cuab yeej, siv nruab nrab zaus electromagnetic cua sov txoj cai kom sai yaj cov seem hlau thiab hlau scraps, belongs rau cov hlau remelting qeb, ntxiv ib tug kab sib chaws alloy muaj pes tsawg leeg los hloov. qhov Performance index ntawm castings.

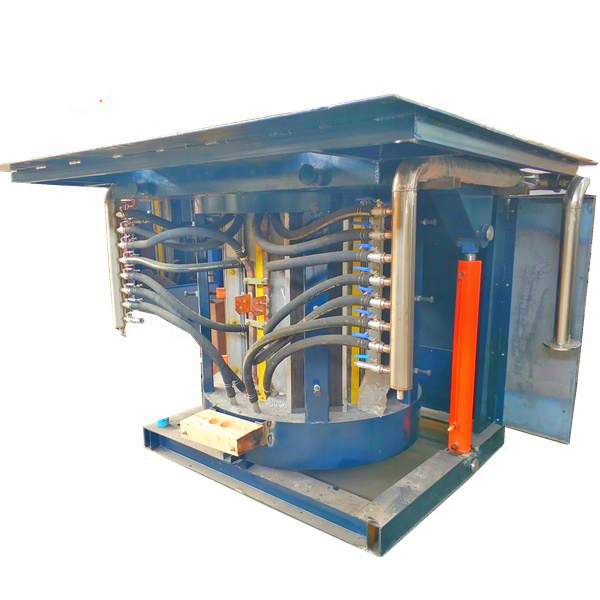

A, Castingnruab nrab zaus rauv profile.

1,Melting hlau cov ntaub ntawv: hlau, hlau, hlau alloy txhuas, alloy tooj liab, stainless hlau thiab lwm yam ntaub ntawv hlau

2, Melting kub: steel 1700 degrees: aluminium alloy 850 degrees;tooj liab alloy 1100 degrees;stainless hlau 1650 degrees

3, Melting zog: nyob ntawm lub sij hawm melting ntawm ib lub cub tawg, 160kw - 12000kw;Piv txwv li, 1 tuj steel seem casting nruab nrab zaus rauv melting zog 750Kw / teev.

4, Dumping hom: rausteel plhaub rauvlub cev feem ntau siv hydraulic dumping rauv;raualuminium plhaub rauv, me me tonnage rauv lub cev feem ntau sivreducerpov tseg rauv.

5,Fais fab hom: casting nruab nrab zaus rauv siv nruab nrab zaus fais fab mov, fais fab mov qauv muab faib ua parallel resonance thiab series resonance

6,Rauv hauv ob sab phlu: casting nruab nrab zaus rauv raws li cov khoom melting sib txawv rauv hauv ob sab phlu yog muab faib ua: acid rauv hauv ob sab phlu, alkaline rauv hauv ob sab phlu thiab nruab nrab-qhov cub hauv ob sab phlu.Rau seem steel melting feem ntau siv acidic rauv cov ntaub ntawv hauv ob sab phlu;rau seem aluminium melting siv alkaline rauv hauv ob sab phlu.

7, Daim ntawv qauv: casting IF rauv yog muab faib ua non-vacuum casting IF rauv thiab nqus casting IF rauv ob daim ntawv.Nqus casting IF rauv yog tsim rau tshwj xeeb alloy smelting.

Qhov thib ob, qhov muaj pes tsawg leeg ntawm cov casting IF rauv.

Aluminium plhaub casting IF rauv qauv: IF fais fab txee, capacitor bank, aluminium plhaub rauv lub cev thiab dej txias cable, reducer, thiab lwm yam.

Steel plhaub casting IF rauv qauv: IF lub hwj chim txee, capacitor txhab nyiaj, steel plhaub rauv lub cev, sib nqus yoke thiab dej txias cable, hydraulic chaw nres tsheb, hluav taws xob hluav taws xob tswb, dej kub tswb, thiab lwm yam.

Peb, casting nruab nrab zaus rauv nta.

1,Foundry nruab nrab zaus rauv cua sov ceev, kub uniformity, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, tsawg oxidation decarburization

2, casting nruab nrab zaus rauv automation degree yog siab, tuaj yeem paub tsis siv neeg tsis siv neeg ua haujlwm, txhim kho cov khoom tsim tau.

3, casting nruab nrab zaus rauv cua sov uniformity, siab precision kub tswj, los ntawm qhov kub thiab txias system tuaj yeem tswj qhov kub thiab txias, kom ntseeg tau tias cov khoom rov ua dua.

4,Casting nruab nrab zaus rauv yog ib qho yooj yim los hloov lub qhov cub lub cev

5,Casting nruab nrab zaus rauv muaj kev tiv thaiv tag nrho nrog dej kub, dej siab, theem poob, overvoltage, overcurrent, voltage / tam sim no txwv, overcurrent pib, tas li tam sim no thiab tsis pib, uas ua rau cov khoom pib smoothly, tiv thaiv kev ntseeg siab thiab ceev, thiab khiav ruaj khov.

6,Lub tshuab hluav taws xob nruab nrab ntawm lub tshuab hluav taws xob muaj qhov siv hluav taws xob tsawg, tsis muaj kuab paug, thiab cov cuab yeej ua tau raws li qhov xav tau ntawm kev tiv thaiv ib puag ncig.