Ukuphosa Iziko leFrekhwensi ePhakathi

FoundryIziko leFrequency ePhakathi iyilwe kwaye yenzelwe imveliso ye-Foundry ukunyibilika kwesinyithi esinyibilikisiweyo kunye nesixhobo sokufudumeza esingenamgangatho ophakathi, ukusetyenziswa kwe-medium frequency frequency ye-electromagnetic ukufudumeza umgaqo wokunyibilikisa ngokukhawuleza isinyithi esilahlwayo kunye nezilahlwa zetsimbi, ziyinxalenye yodidi lokunyibilikisa isinyithi, yongeza ukwakheka kwealloyi yomkhondo ukuze utshintshe. isalathiso sokusebenza sokusaswa.

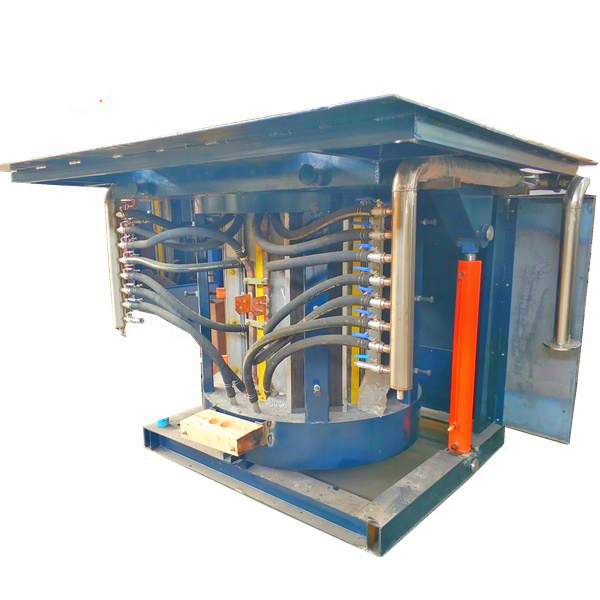

A, Ukuphosamedium frequency eziko iprofayile.

1,Izinto zesinyithi ezinyibilikayo: intsimbi, intsimbi, ialluminiyam, ialloyi yobhedu, intsimbi engenanto kunye nezinye izinto zentsimbi.

I-2, Ukushisa okunyibilikayo: intsimbi ye-1700 degrees: i-aluminium alloy 850 degrees;ialloy yobhedu 1100 degrees;insimbi engenasici 1650 degrees

3, Amandla okunyibilika: kuxhomekeke kwixesha lokunyibilika kwesithando somlilo esinye, 160kw – 12000kw;umzekelo, itoni e-1 yesilaphu sentsimbi ephosa amandla aphakathi kwesithando sokunyibilikisa i-750Kw / iyure.

4, Ukulahla imo: kubaiqokobhe lentsimbi ezikoumzimba ngokubanzi usebenzisa iziko lokulahla i-hydraulic;ngenxaaluminium iqokobhe eziko, i-tonnage encinci yesithando somlilo isetyenziswa ngokubanziisinciphisiiziko lokulahla.

5,Imowudi yamandla: ukuphosa isithando somlilo esiphakathi usebenzisa unikezelo lwamandla ombane ophakathi, unikezelo lwamandla ombane lwahlulahlulwe ngokweresonance efanayo kunye nothotho lweresonance.

6,Udidi lwesithando somlilo: ukuphosa isithando somlilo esiphakathi ngokwezinto ezinyibilikayo ezahlukeneyo zesithando somlilo sahlulwe saba: isithando somlilo esine-asidi, isithando somlilo sealkaline kunye nesithando somlilo esiphakathi.Ukunyibilika kwentsimbi ye-scrap ngokuqhelekileyo sebenzisa izixhobo zokugqoka zesithando somlilo;ukwenzela ukunyibilika kwe-alloy ye-alkaline ye-alkaline enyibilikayo.

I-7, ifom yesakhiwo: ukuphosa IF i-furnace yahlulwe ibe yi-non-vacuum casting IF isithando somlilo kunye ne-vacuum casting IF isithando somlilo iifom ezimbini.I-vacuum casting IF i-furnace ifanelekile kwi-alloy smelting ekhethekileyo.

Okwesibini, ukubunjwa kwesithando somlilo se-IF.

I-Aluminiyam iqokobhe ephosa i-IF i-furnace structure: Ikhabhinethi yamandla ye-IF, ibhanki ye-capacitor, i-aluminium igobolondo lesithando somlilo kunye nekhebula lokupholisa amanzi, isinciphisi, njl.

Steel shell casting IF i-furnace structure: IF ikhabhinethi yamandla, ibhanki ye-capacitor, umzimba wesithando somlilo wegobolondo, ijoka yamagnetic kunye nekhebula lokupholisa amanzi, isikhululo se-hydraulic, i-alamu yokuvuza, i-alamu yobushushu bamanzi, njl.

Ezintathu, ukuphosa okuphakathi kweempawu zesithando somlilo.

1,Isantya sokufudumeza isithando se-Foundry medium frequency, ukufana kobushushu, ukonga amandla kunye nokhuseleko lokusingqongileyo, i-oxidation decarburization encinci.

2, ukuphosa idigri ye-automation ye-furnace ephakathi iphezulu, inokuqonda ukusebenza okuzenzekelayo okungasetyenziswanga, ukuphucula imveliso yabasebenzi.

I-3, ukuphosa ukufudumeza okufanayo kwesithando somlilo esiphakathi, ulawulo oluchanekileyo oluchanekileyo, ngenkqubo yokulawula ubushushu kunokulawula ngokuthe ngqo ubushushu, ukuqinisekisa ukuba ukuphindaphindwa kwemveliso.

4,Isithando somlilo esiphakathi sokuphosa kulula ukubuyisela umzimba wesithando somlilo

5,Isithando somlilo esiphakathi sikhuselwe ngokupheleleyo ngobushushu bamanzi, uxinzelelo lwamanzi, ilahleko yesigaba, i-overvoltage, i-overcurrent, i-voltage / yangoku umda, ukuqala kwe-overcurrent, i-current current kunye ne-buffer start, eyenza ukuba izixhobo ziqale kakuhle, zikhusele ngokuthembekileyo kwaye ngokukhawuleza, kwaye ziqhube. ngokuzinzileyo.

6,Isithando somlilo esiphakathi sinosetyenziso oluphantsi lwamandla, akukho lungcoliseko, kwaye isixhobo sihlangabezana neemfuno zokhuseleko lokusingqongileyo.