Rolling millstuaj yeem raug cais raws li lawv cov qauv thiab muaj cov yam ntxwv ntawm tus lej ntawm cov yob thiab lawv txoj haujlwm nyob rau hauv qhov chaw sawv ntsug: dov mills nrog kab rov tav yob, dov mills nrog kev sib nrig sib txuas thiab oblique kev npaj thiab lwm yam tshwj xeeb dov mills.

1. Ob-siab dov zebLub tshuab dov no muaj cov qauv yooj yim, txhim khu kev qha, thiab yog tsav los ntawm DC lub cev muaj zog.Nws yog siv los ua ob-siab reversible blooming zeb, uas muaj peev xwm reciprocate lub dov ntawm steel ingots rau hauv ntau yam duab plaub.Ob-siab reversing mills kuj tseem siv tau los yob txoj kab teeb thiab phaj.

Ob peb lub yob sawv ntsug yog tsav los ntawm DC lossis AC lub cev muaj zog hauv cov pab pawg los tsim cov kab txuas txuas ntxiv, uas tuaj yeem tsim cov pob zeb thiab cov ntu, thiab muaj cov yam ntxwv ntawm cov khoom lag luam siab.Nws kuj yog siv nyob rau hauv pawg-rolled ntawv, txias-dov strip thiab txias-dov daim tawv nqaij-dhau zeb txheej txheem.

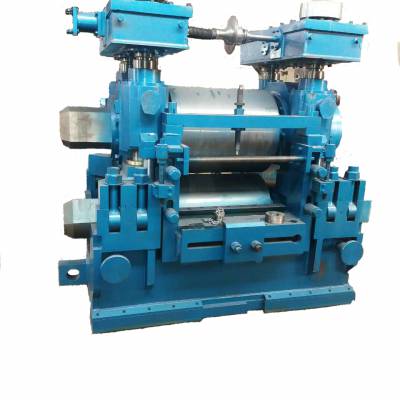

2. Covpeb-roll zebtuaj yeem yob ob txoj kev dov ntawm tib qho chaw sawv ntsug, thiab lub tshuab dov tsis tas yuav thim rov qab.Ob peb lub yob mills yog tsav los ntawm AC lub cev muaj zog los ntawm lub reducer thiab lub hauv paus iav, uas tuaj yeem paub txog kev sib hloov thiab ntau qhov kev hla.dov.Rau billet thiab seem ntau lawm.

3. Peb-roller Lauter mill Qhov txoj kab uas hla ntawm nruab nrab yob ntawm lub zeb no yog me dua li ntawm cov yob sab sauv thiab qis, thiab ntab ntawm cov yob sab saud thiab qis.Rolling mills yog nruab nrog lub cev muaj zog los tsav cov yob sab saud thiab qis, nruab nrab yob yog tsav los ntawm kev sib txhuam, thiab cov khoom dov tuaj yeem dov rov qab rau ntau qhov kev hla.

4. Muab ob npaug rau ob-siab dov zeb Qhov kev ua haujlwm ntawm lub tshuab dov no zoo ib yam li peb-siab dov zeb, tab sis cov yob hloov thiab dhau kev teeb tsa yooj yim dua.

5. Plaub-siab rolling zeb muaj lub sab sauv thiab qis dua ob qhov loj thaub qab yob thiab ob lub yob ua haujlwm me me.Cov yob ua haujlwm me me tuaj yeem txo qhov chaw sib cuag, txo qhov kev sib tw, thiab cov yob rov qab ua lub luag haujlwm txhawb nqa, txo qhov kev khoov ntawm cov yob ua haujlwm thiab ua kom cov rigidity ntawm cov yob yob.Txhawm rau kom ruaj khov ntawm cov yob ua haujlwm, cov yob ua haujlwm feem ntau raug cuam tshuam los ntawm qhov deb me me hauv qhov kev taw qhia dov los tiv thaiv qhov nruab nrab ntawm cov yob los ntawm kev hla vim yog cov kabmob clearance.Plaub-siab mills feem ntau yog siv rau strip dov.

6. Multi-yob zeb Nyob rau hauv thiaj li yuav hloov mus rau high-precision kev loj hlob ntawm txias-dov strip loj, rau-siab, kaum ob-siab thiab nees nkaum-siab dov mills tau tshwm sim.Nees nkaum-siab mills tuaj yeem yob tawm nyias strips thiab foils ntawm ob peb μ.Tsis tas li ntawd, txhawm rau txhawm rau txhim kho qhov nruj ntawm cov dov zeb thiab ua kom yooj yim rau cov qauv ntawm cov dov zeb, ntau hom ntau yob yob mills tau tshwm sim.Lub eccentric yim-siab dov zeb muaj cov yam ntxwv ntawm txoj kab uas hla me me ntawm kev ua haujlwm yob, muaj peev xwm ua kom nyias nyias, thiab cov qauv yooj yim, thiab tuaj yeem rov ua dua nrog plaub-siab dov zeb.Lub yob ua hauj lwm nyob rau ntawm ib tug tej yam eccentric txoj hauj lwm, thiab lub axis ntawm lub yob ua hauj lwm yog ruaj khov los ntawm lub intermediate yob thiab sab kev them nyiaj yug yob, thiab cov kev them nyiaj yug yob yog tsav los ntawm lub cev muaj zog los ntawm lub rooj zaum iav.

7. Planetarydov zebLub planetary dov zeb pib nyob rau hauv 1950s.Nws muaj cov yam ntxwv ntawm kev txo qhov loj (txo tus nqi ntawm 90 ~ 95%) thiab yog siv los tsim kub dov strip coils.Lub rooj zaum muaj cov menyuam pub noj thiab cov ntiaj chaw.Yob muaj pes tsawg leeg.Cov menyuam pub pub rau qhov tsis muaj qhov txo qis los ua ib qho kev thrust, thiab xa cov dov mus rau lub ntiaj teb cov menyuam rau dov.Lub planetary yob muaj nees nkaum khub ntawm kev ua haujlwm yob thiab ib khub ntawm thaub qab yob.Nees nkaum khub ntawm kev ua haujlwm yob txuas nrog lub tshuab synchronizing, thiab cov yob ua haujlwm tau tsav los ntawm cov kabmob sib tw thiab tuaj yeem tig ib ncig ntawm kev txhawb nqa yob raws li lub ntiaj teb.Cov yob ua hauj lwm muaj kev sib raug zoo ntawm kev sib tw rau cov khoom dov, uas zoo ib yam li cov yob bearing roller txoj kev sib raug zoo rau lub nplhaib sab nraud.Lub dov Tshuag yog raug mus ua tiav dov los ntawm kaum ob ntawm khub ntawm kev ua haujlwm yob, thiab qhov tshwm sim ntawm cov khoom deformation yog loj deformation.Hom dov zeb no feem ntau yog siv rau stainless hlau sawb ntau lawm txawv teb chaws.

Post lub sij hawm: Aug-31-2022