Rolling mills can be classified according to their structure and are characterized by the number of rolls and their position in the stand: rolling mills with horizontal rolls, rolling mills with mutually perpendicular rolls and oblique arrangements and other special rolling mills.

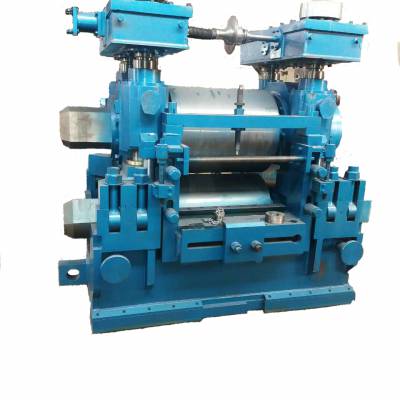

1. Two-high rolling mill This rolling mill has a simple structure, reliable operation, and is driven by a DC motor. It is used as a two-high reversible blooming mill, which can reciprocate the rolling of steel ingots into various rectangular billets. Two-high reversing mills can also be used to roll rail beams and plate.

Several two-roll stands are driven by DC or AC motors in groups to form a continuous rolling line, which can produce billets and sections, and has the characteristics of high productivity. It is also used in stack-rolled sheet, cold-rolled strip and cold-rolled skin-pass mill processes.

2. The three-roll mill can roll two-way rolling on the same stand, and the rolling mill does not need to be reversed. Several three-roll mills are driven by an AC motor through a reducer and a gear base, which can realize reciprocating and multiple passes. rolling. For billet and section production.

3. Three-roller Lauter mill The diameter of the middle roll of this mill is smaller than that of the upper and lower rolls, and floats between the upper and lower rolls. The rolling mill is equipped with a motor to drive the upper and lower rolls, the middle roll is driven by friction, and the rolling stock can be rolled back and forth for multiple passes.

4. Double two-high rolling mill The function of this rolling mill is similar to that of three-high rolling mill, but the roll adjustment and pass configuration are more convenient.

5. Four-high rolling mill consists of upper and lower two larger backup rolls and two smaller work rolls. Smaller work rolls can reduce the contact area, reduce the rolling force, and the backup rolls play a supporting role, reducing the bending of the work rolls and increasing the rigidity of the rolling mill. In order to stabilize the work rolls, the work rolls are often offset by a small distance in the rolling direction to prevent the centerline of the rolls from crossing due to bearing clearance. Four-high mills are mostly used for strip rolling.

6. Multi-roll mill In order to adapt to the high-precision development of cold-rolled strip size, six-high, twelve-high and twenty-high rolling mills have appeared. Twenty-high mills can roll out thin strips and foils of several μ. In addition, in order to improve the rigidity of the rolling mill and simplify the structure of the rolling mill, various types of multi-roll rolling mills have appeared. The eccentric eight-high rolling mill has the characteristics of small diameter of work rolls, capable of thinning, and simple structure, and can be retrofitted with a four-high rolling mill. The work roll is located at a certain eccentric position, and the axis of the work roll is kept stable by the intermediate roll and the side support roll, and the support roll is driven by the motor through the gear seat.

7. Planetary rolling mill The planetary rolling mill began in the 1950s. It has the characteristics of large reduction (reduction rate of 90~95%) and is used to produce hot-rolled strip coils. The stand consists of feed rollers and planets. Roll composition. The feed roller gives the blank a certain reduction to form a certain thrust, and sends the rolled piece to the planetary roller for rolling. The planetary roll consists of twenty pairs of work rolls and a pair of backup rolls. Twenty pairs of work rolls are connected by a synchronizing mechanism, and the work rolls are driven by the bearing races and can rotate around the support rolls as a planet. The work roll has a rolling motion relationship to the rolling stock, which is similar to the rolling bearing roller’s motion relationship to the outer ring. The rolling stock is subjected to successive rolling by dozens of pairs of work rolls, and the result of accumulated deformation is large deformation. This kind of rolling mill is mostly used for stainless steel strip production abroad.

Post time: Aug-31-2022