Ukuze ukusebenza kwansuku zonke kwamabhizinisi, imishini nemishini idlala indima ebalulekile, kuphela lapho imishini nemishini isebenza kahle, ukudala izinzuzo ezinhle zezomnotho zamabhizinisi.Emshinini wokugaya, iumshini wokugaya idlala indima ebalulekile, kodwa uma kunezinkinga nge-lubrication yemishini, izothinta ukusebenza okuvamile kwe-rolingmngiyagulamane.Ucwaningo olufanele kanye nokwenza kukhombisa ukuthi ngemuva kweimishini rolling steel efektri, impilo yayo yesevisi incike kakhulu emsebenzini wokugcoba owenziwe kahle, ukuguga okungavamile kubangele cishe u-80% wezingxenye zomonakalo, ukugcoba okubi kwaholela ekuhlulekeni kwemishini engu-60%.Embonini yemishini, ngenxa yokungagcobi kahle kwenyuse izindleko zemishini ngenani eliphelele lengxenye efinyelela ku-30%.Ingxenye yokwehluleka kokuthwala okubangelwa ukugcotshwa okuncane ngokumangazayo ithatha ama-54% yenani eliphelele lokwehluleka ukuthwala.Kungabonakala, ukwehluleka kokugcoba ngakolunye uhlangothi, imishini yomshini ngokwayo ibangele umonakalo;ngakolunye uhlangothi, futhi yavimbela ukusebenza okuvamile komugqa wokukhiqiza, ezinzuzweni zezomnotho zebhizinisi ezilethwa umthelela omubi.Ngakho-ke, isimo sokugcotshwa kwe-imishini rolling steel ukuphatha sekuyimpoqo.

Rolingmngiyagulamane izidingo zokugcoba

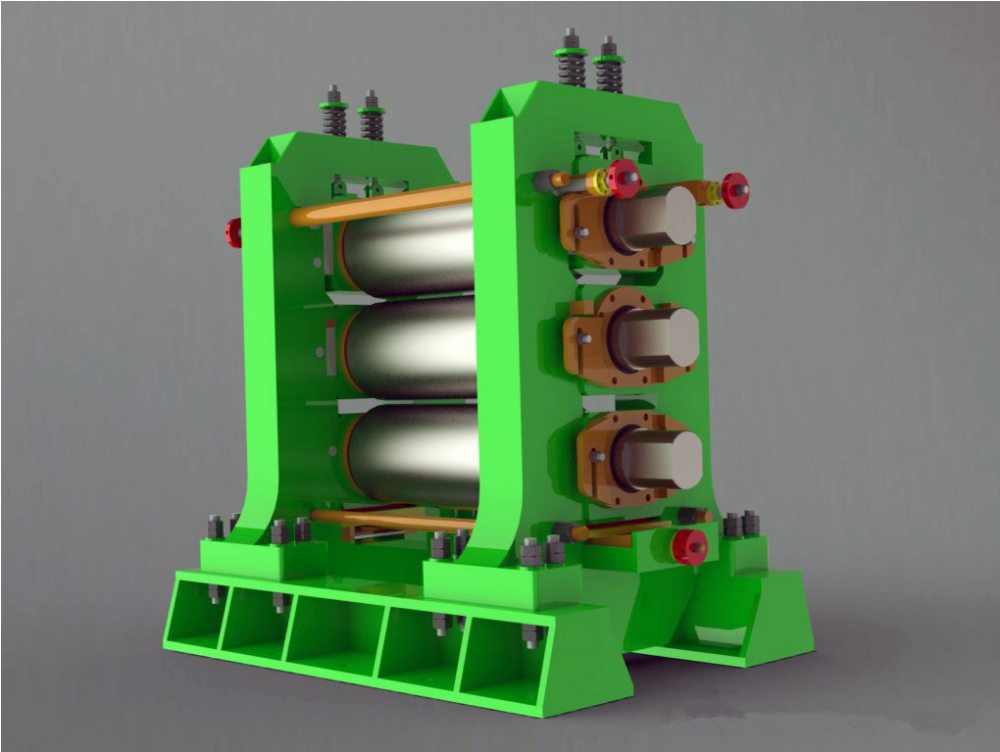

Insimbiumshini wokugaya izingxenye ikakhulukazi zifaka injini, umshini wokuhlanganisa oyinhloko, umshini wokuhlanganisa wangaphambili nangemuva.Izidingo ezilandelayo zenzelwe ukugcoba: okokuqala, ukugcoba kwamafutha amancane;okwesibili, ukugcoba uwoyela owomile;okwesithathu, isivinini kanye nokunemba okuphezuluumshini wokugaya ama-bearings asebenzisa uwoyela negesi kanye nokugcoba inkungu kawoyela.

Ngesikhathi sensimbi eginqikayo, ukuze kuthuthukiswe ikhwalithi yomkhiqizo futhi kuthuthukiswe ukunwetshwa kwezinto ezigoqiwe, inqubo yokuthambisa kanye nezinto zokupholisa zidinga ukungezwa phakathi kwama-roll kanye nezinto ezigoqiwe.Ngokuvamile, i-umshini wokugaya idinga i-lubrication yenqubo kanye nemidiya yokupholisa enezici ezilandelayo: okokuqala, umthamo omuhle wokupholisa;okwesibili, izindleko eziphansi, ukufinyelela kalula emithonjeni kawoyela;okwesithathu, amafutha afanelekile;Okwesine, kungaba kuzuzwe imiqulu kanye nemikhiqizo surface flushing kanye yokuhlanza;okwesihlanu, ukuhlunga okungcono;okwesithupha, izakhiwo ezinhle zokudonsa umcu ogoqekayo;okwesikhombisa, ukumelana ne-oxidation, ukuzinza ngokomzimba namakhemikhali kanye nokumelana nokugqwala;okwesishiyagalombili, hhayi Akuyona ingozi empilweni yomuntu.

Isikhathi sokuthumela: Oct-21-2022