Continuous Caster – Runxiang

Continuous Caster – Runxiang Detail:

Product Description:

| According to the structure and shape | Divided into vertical continuous casting machine, vertical bending continuous casting machine | Number of strands | Divided into single-strand, double-strand or multi-strand continuous casting machines |

| According to the casting section | Divided into slab continuous casting machine, billet continuous casting machine | Application | Metal forging |

The production process of continuously casting high-temperature molten steel into a slab with a certain cross-sectional shape and a certain size is called continuous steel casting.

The equipment required to complete this process is called continuous casting equipment. The electromechanical-hydraulic integration of casting equipment, continuous casting machine body equipment, cutting area equipment, dummy bar collection and conveying equipment constitutes the core equipment of continuous steel casting, which is customarily called continuous casting machine.

Continuous casting machine production process.

The high-temperature molten steel is continuously poured into one or a group of water-cooled copper molds, and the molten steel gradually solidifies along the periphery of the mold into a billet shell. After the molten steel level rises to a certain height, the billet shell solidifies to a certain thickness. The billet is pulled out, and the billet is completely solidified by water spray cooling in the secondary cooling zone, and is cut to length by the cutting device according to the requirements of rolling. This process of directly pouring high-temperature molten steel into billets is called continuous casting. Its appearance has fundamentally changed the ingot-rolling process that has dominated for a century. Because it simplifies the production process, improves the production efficiency and metal yield, saves energy consumption, greatly reduces the production cost, and has the advantages of good billet quality and other advantages. In today’s steelmaking enterprises, whether it is long-process steelmaking or short-process steelmaking, the equipment of continuous casting machines is almost inevitable.

| Casting shape | Screen size | Model of continuous casting machine |

| Garden bloom | 60-250 | R3000-R8000 |

| Square Billet | 60*60-250*250 | R3000-R8000 |

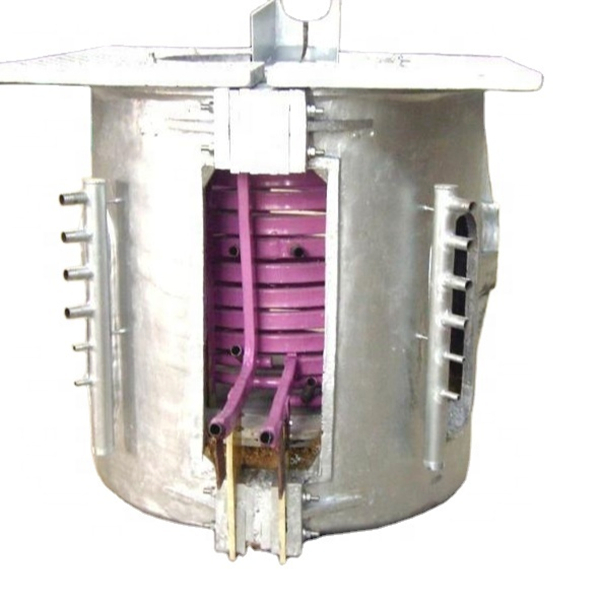

Product detail pictures:

Related Product Guide:

We not only will try our great to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Continuous Caster – Runxiang , The product will supply to all over the world, such as: Portland, UK, Indonesia, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.