In industrial manufacturing, rolling mills play a vital role in the production of high-quality steel bars. These factories require custom industrial equipment that can handle extreme pressure and heat to form metal into the desired shape and size. For these machines to run efficiently and effectively, the flywheel is an essential component that cannot be ignored.

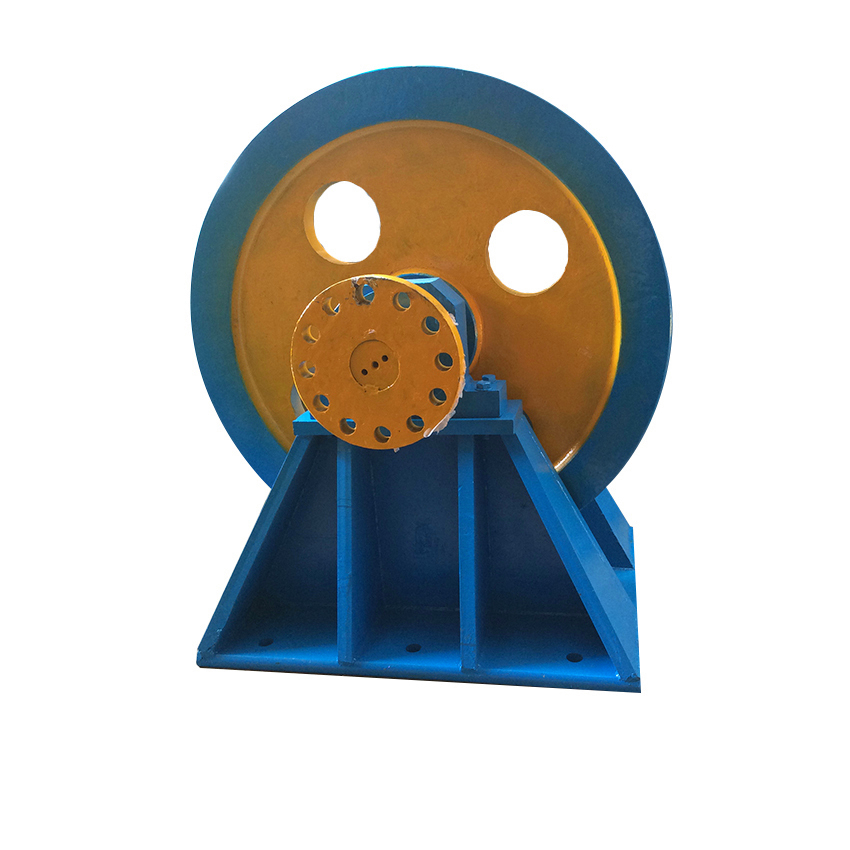

At its core, a flywheel is a mechanical device that stores energy as it spins and releases it when needed. This mechanism is critical for industrial equipment, especially rolling mills that require high power and speed. The flywheel helps to stabilize the rotation of the machine, reducing vibration and noise. This results in a more efficient and productive operation.

A rolling mill equipment manufacturer that understands the importance of flywheel is Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd. The company specializes in the design, production and sale of custom-made industrial equipment for steel bar rolling lines. The company offers a range of products including rolling mills, rolling equipment, rolls, heating furnaces and corresponding accessories to meet the unique needs of customers.

Rebar rolling lines require flywheels that are specially designed to handle the enormous forces generated by the operation of the rolling mill. Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd. offers flywheels in different sizes, designed to function optimally according to customers’ specific production requirements.

In addition to increasing the productivity of your rolling mill, a properly functioning flywheel can provide significant cost savings. By helping to stabilize machine rotation, flywheels reduce wear and tear on other components such as bearings and gears. In the long run, this means less maintenance and lower repair costs.

Additionally, flywheels play a vital role in reducing energy consumption. With a well-designed flywheel, the machine can run more efficiently, requiring less energy to achieve the same output. This results in lower energy costs and lowers the carbon footprint of the entire manufacturing process.

In conclusion, the flywheel is a vital component in rolling mill equipment. A well-designed flywheel helps to stabilize machine rotation, reduce vibration and noise, increase energy efficiency and reduce overall production costs. A thorough understanding of the importance of flywheels and how they affect a customer’s production system is critical for any rolling mill equipment manufacturer, like Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd.

Investing in high-quality custom industrial equipment, including flywheels, can yield long-term economic benefits for manufacturers. At the same time, it demonstrates a commitment to sustainable manufacturing practices. By working with a trusted supplier, like Guangxi Runxiang Machinery Equipment Manufacturing Co., Ltd., manufacturers can ensure they have the right equipment to meet their business goals.

Post time: May-31-2023