1.Khangelairoling ilitye lokusila yonke imihla ngayo nayiphi na ingxolo engaqhelekanga, khangela indawo edityanisiweyo kuyo nayiphi na ingxolo engaqhelekanga kunye nesenzeko sokufudumeza, nokuba ibholithi yokudibanisa ikhululekile.

2.Khangela ukuba kukho isixa esikhulu seempawu zokuvuza kweoyile kwisitywina sebhokisi yokuhanjiswa kwangaphambili kokugqiba kunye neflange yoqhagamshelo, ukuvuza okuncinci kuvunyelwe, kodwa kufuneka kucinywe, phulaphula ukuba kukho ingxolo engaqhelekanga evela kwiigiya okanye iibheringi.

3.Khangela ukuba i-oyile kunye negesi yokuthambisa i-PU umbhobho wepaneli yebhokisi yokugqitywa kwangaphambili iyawa ukuze uqinisekise ukuba iindawo zokuthambisa zikwimeko efanelekileyo yokuthambisa.

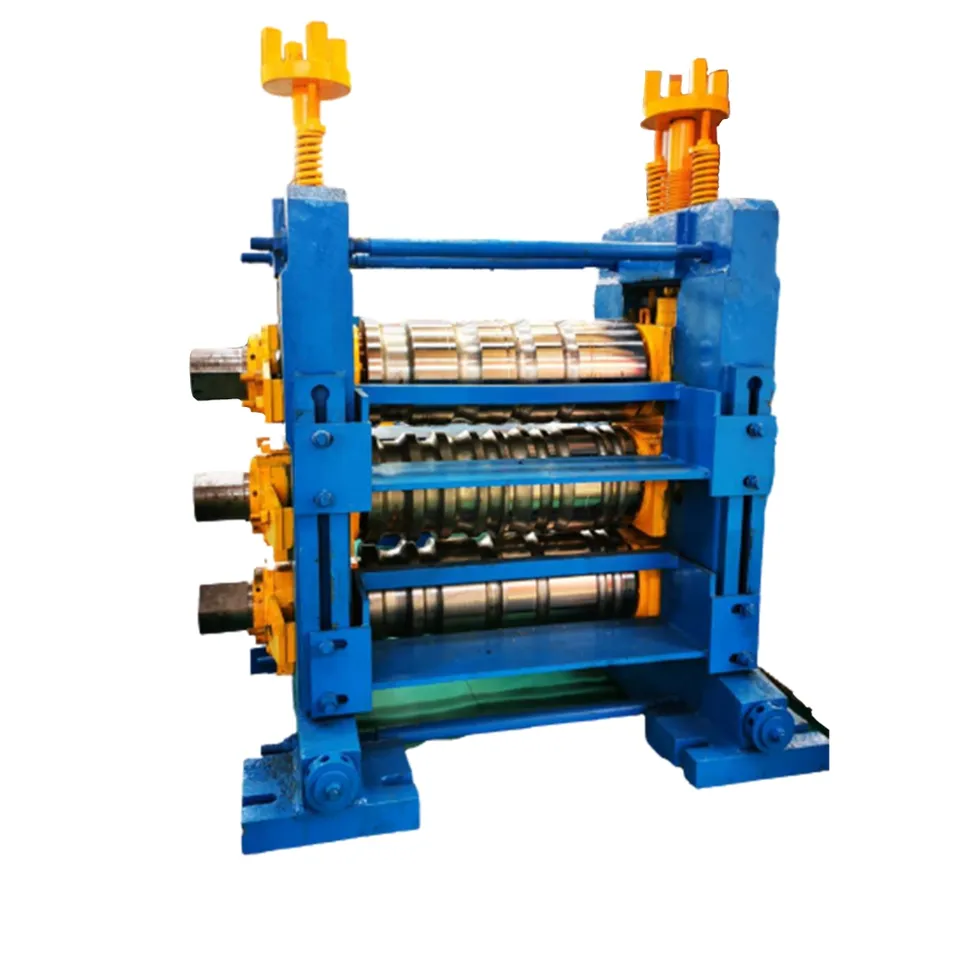

4.Jonga yonke imihla ukuba kukho ukuvuza kweoyile kumphezulu odityanisiweyo webhokisi yerola kunye nebhokisi yecone, ukuba kukho ukuvuza kweoyile encinci, umlebe ophindwe kabini kunye ne-O-ring seal kufuneka itshintshwe ngoomatshini abazikhethelayo.

5.Yonke imihla kufuneka ijonge iibhokisi yegiya, zama ukuphulaphula igiya kunye nokuthwala nasiphi na isandi esingaqhelekanga, khangela ubushushu bebhokisi ekuthwaleni.

6.Lonke uhlolo lweshifti yoxinzelelo lweoyile yokuthambisa, ukuhamba, uxinzelelo lwamanzi okupholisa, aluyi kuba ngaphantsi kwexabiso elichaziweyo.

7.Fokanye iyunithi yokugqibezela ukuqengqeleka 10 zokusila ukuba zilinganiswe kabini shift sub-vibration, ixabiso elifunekayo lokungcangcazela≤I-4.5 mm / s, efana nobukhulu kunomgangatho, kufuneka ithathele ingqalelo ukujonga imeko yophuhliso kwaye yazise ngokukhawuleza umphathi weshifti.Ukuba i-vibration ihlala izinzile kuluhlu oluphezulu lwexabiso lokungcangcazela, imveliso ingaqhubeka nokugcina.

8.Ukuba kukho i-alarm ephosakeleyo yokugqiba iyunithi yokuqengqeleka ngexesha lokuvelisa, abasebenzi bokulondoloza kufuneka bahlolisise ngenyameko kwaye baqinisekise ngaphambi kokuba bavume ukuqhubeka nokujika.

9.Ukuba iiparitha zebhokisi ze-roller zifunyenwe zigqithise kakhulu umgangatho ngexesha lokuhlola, ibhokisi ye-roller kufuneka itshintshwe ngokukhawuleza.

10.Jonga yonke imihla ukuba i-valve ye-solenoid ye-pinch feed roller ilungile kwaye ukuba imigca yomoya kunye namanzi igudile, kwaye ujongane neengxaki ezifunyenwe ngexesha.

11.Qwalasela ukuguga komjelo wokungena kumatshini wokutshica yonke imihla, kwaye uwubuyisele ngexesha xa ukunxitywa kukubi.

12.Jonga ukungcangcazela kwewunomsindorolingmuyagula ngexesha lokusebenza, ukuba ukungcangcazela kufunyaniswa ukwanda, kufuneka kuyekwe ukujonga ukuba ukufakwa kwetyhubhu yokutshica kukhuselekile, khangela ukuba udibaniso lwebholithi lukhuselekile na.wunomsindoplantsukugqobhozami-achine kwaye i-hollow shaft iqinile.

13.Jonga rhoqo ukunxiba kwesethi ephilayo yee-roller kunye nokugudiswa kweoli kunye ne-gas lubrication ye-rollers imihla ngemihla, kwaye utshintshe ngokukhawuleza ukugcinwa kwimeko ethile.

Ixesha lokuposa: Mar-27-2023