1.Hlolairoling isigayo nsuku zonke nganoma imuphi umsindo ongajwayelekile, bheka ukuhlangana ukuze uthole noma yimuphi umsindo ongavamile nokushisa, noma ngabe ibhawudi yokuhlanganisa ikhululekile.

2.Hlola ukuthi likhona yini inani elikhulu lezimpawu zokuvuza kwamafutha esigxivini sebhokisi lokudlulisela eliginqikayo ngaphambi kokuqeda kanye ne-flange yokuxhumana, ukuvuza okuncane kuvunyelwe, kodwa kufanele kusulwe kuhlanzeke, lalela ukuthi kukhona yini umsindo ongajwayelekile ovela kumagiya noma ama-bearings.

3.Hlola ukuthi ingabe ipayipi le-PU lokuthambisa likawoyela negesi lephaneli yebhokisi lebhokisi langaphambi kokuqedwa liyawa yini ukuze uqiniseke ukuthi izindawo zokuthambisa zisesimweni esihle sokuthambisa.

4.Hlola nsuku zonke ukuthi ingabe kukhona ukuvuza kwamafutha endaweni ehlanganisiwe yebhokisi le-roller nebhokisi le-cone, uma kukhona ukuvuza kwamafutha amancane, izindebe eziphindwe kabili kanye ne-O-ring seal kufanele kushintshwe umshini ozikhethela wona.

5.Nsuku zonke kufanele uhloleibhokisi legiya, zama ukulalela igiya nokuthwala noma yimuphi umsindo ongaziwa, hlola izinga lokushisa kwebhokisi ekuthwaleni.

6.Konke ukuhlolwa kweshifu yokucindezela kwamafutha okugcoba, ukugeleza, ukucindezela kwamanzi okupholisa, akufanele kube ngaphansi kwevelu eshiwo.

7.Fnoma iyunithi yokuqedela engu-10 yokugaya ukuze ikalwe kabili ukudlidliza okungaphansi kwe-shift, inani lokudlidliza elidingekayo≤4.5 mm/s, njengokukhulu kunaleli zinga, kudingeka ukunaka ukubheka ukuthuthuka kwayo futhi yazise umphathi weshifu ngokushesha.Uma ukudlidliza kuhlala kuzinzile ebangeni eliphezulu lamanani okudlidliza, ukukhiqizwa kungaqhubeka nokunakekela.

8.Uma kune-alamu yephutha yeyunithi yokuqedela ngesikhathi sokukhiqiza, izisebenzi zokunakekela kufanele zihlole ngokucophelela futhi ziqinisekise ngaphambi kokuvuma ukuqhubeka nokujika.

9.Uma imingcele yebhokisi le-roller itholakala ukuthi yeqe kakhulu izinga ngesikhathi sokuhlolwa, ibhokisi le-roller kufanele lishintshwe ngokushesha.

10.Hlola nsuku zonke ukuthi i-solenoid valve ye-pinch feed roller iphelele yini nokuthi imigqa yomoya nezamanzi ibushelelezi yini, futhi ubhekane nezinkinga ezitholakala ngesikhathi.

11.Hlola ukuguga komsele ongenisayo womshini wokuphalaza nsuku zonke, futhi uwushintshe ngesikhathi lapho ukuguga kubucayi.

12.Hlola ukudlidliza kwe-wirerolingmngiyagula ngesikhathi sokusebenza, uma ukudlidliza kutholakala ukuthi kwanda, kufanele kumiswe ukuze kuhlolwe ukuthi ukufakwa kwe-tube yokuphalaza kuphephile, hlola ukuthi uxhumano lwe-bolt phakathiwirepkhalasumgodimi-achine kanye ne-hollow shaft iqinile.

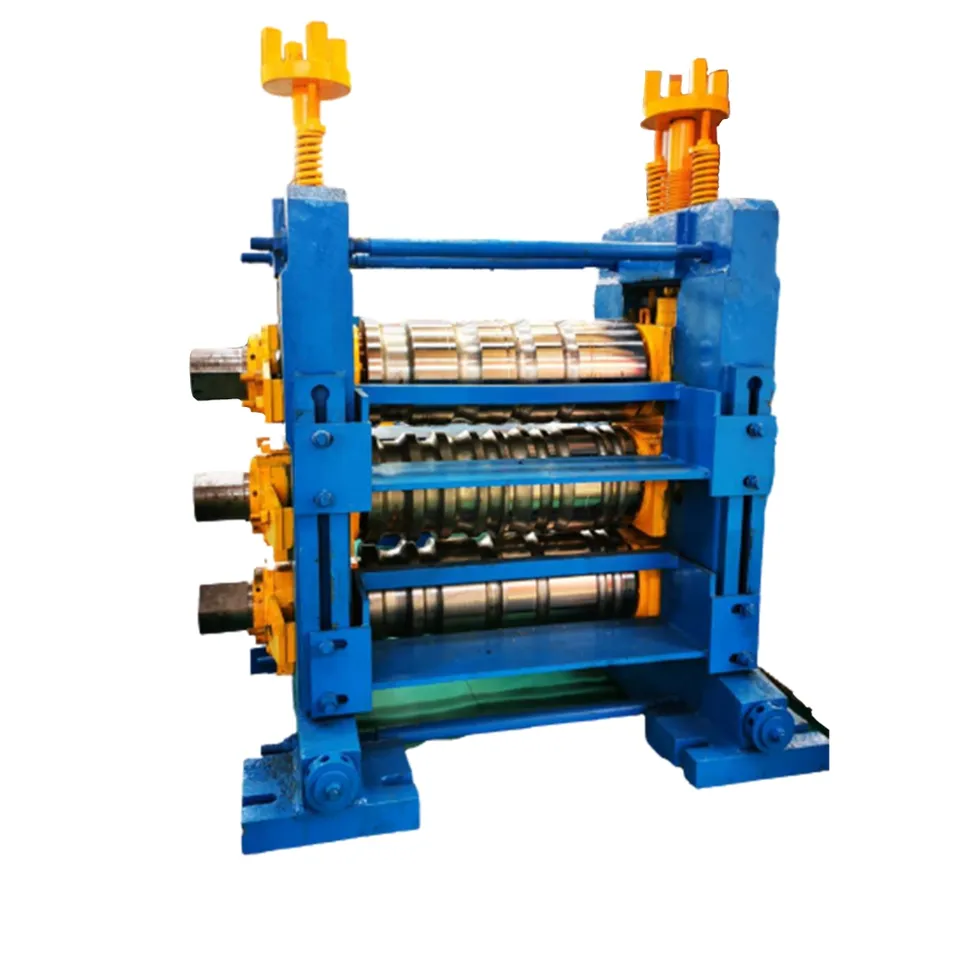

13.Hlola njalo ukugqokwa kwesethi ephilayo yama-roller kanye nokushelela kwamafutha negesi ukugcotshwa kwama-roller nsuku zonke, futhi ubuyisele ngokushesha ukugcinwa kwesimo esithile.

Isikhathi sokuthumela: Mar-27-2023