Products

-

Rotational Flying Shears

The shearing machine for rolling pieces in transverse shearing operation is called flying shear. It is a processing equipment that can quickly cut iron plates, steel pipes and paper rolls. The product in rolling bar shearing has the characteristics of low power consumption and low investment cost.

-

Curved Arm Flying Shear

The shearing machine for rolling pieces in transverse shearing operation is called flying shear. It is a processing equipment that can quickly cut iron plates, steel pipes and paper rolls. The product in rolling bar shearing has the characteristics of low power consumption and low investment cost.

-

Ni Cr Mo cold hardening centrifugal composite

Scope of application: medium and finish rolling stands of profile, bar and wire mills. -

Cold bed

1. Cold frame uses the heat source of sunlight to create a seedbed suitable for seedling growth temperature under the enclosure and transparent covering equipment within a certain range. 2. The cooling bed is a worktable for the metallurgical steel rolling industry to effectively cool the rolled products (threaded steel, round steel, steel pipe, etc.). The cooling bed is composed of mechanical transmission system, water cooling system, working table of cooling bed, fixed support, etc. Cooling... -

Smelting equipment

Smelting is one of the casting production processes. The pyrometallurgical process in which metal materials and other auxiliary materials are put into the heating furnace for melting and quenching and tempering, and certain physical and chemical changes occur in the materials in the furnace at high temperature (1300 ~ 1600K), so as to produce crude metal or metal enrichment and slag. In addition to concentrate, calcine, sinter, etc., sometimes it is necessary to add flux to make the charge ea... -

Bearing

Bearing is a kind of mechanical element that limits the relative motion to the required range of motion and reduces the friction between moving parts. The design of bearings can provide free linear motion of moving parts or free rotation around a fixed axis, and can also prevent movement by controlling the vector of normal force acting on the moving parts. Most bearings promote the required movement by minimizing friction. Bearings can be widely classified according to different methods, su... -

Dust Collector

Dust removal equipment refers to the equipment that separates dust from flue gas, also known as dust remover. Everyone has the experience of wearing masks, which is a simple filtering and dust removal equipment. [1] The dust removal mechanism of dust removal equipment is very simple. Like the dust removal mechanism of mask, it is realized by mechanical interception of fly ash particles in flue gas by filter materials. However, in addition, the first received fly ash particles also form a st... -

Frame

1. Base material: the base material shall be correctly selected according to its structure, process, cost, production batch and production cycle, Common are: (1) Cast iron: it is easy to cast into parts with complex shape; The price is cheaper; Cast iron has large internal friction and good vibration resistance. his The disadvantages are long production cycle and high single piece production cost; Castings are easy to produce waste products and the quality is not easy to control; Machining al... -

Vertical mill

The utility model relates to a vertical rolling mill, which comprises a rolling mill body and a roll drive motorMachine, gear box, universal joint shaft, rolling mill bracket and motor support platform;The rolling mill body comprises a frame and two rollsThe axis is perpendicular to the horizontal plane; The output of the roll drive motor.The shaft is connected with the input shaft of the gearbox, and the two output shafts of the gearbox are dividedDo not connect the two rolls of the rolling ... -

Power Distribution Cabinet

The distribution cabinet (box) is divided into power distribution cabinet (box), lighting distribution cabinet (box) and metering cabinet (box), which is the last level equipment of the distribution system. Distribution cabinet is the general term of motor control center. The distribution cabinet is used in occasions with scattered load and few circuits; Motor control center is used for occasions with concentrated load and many circuits. They distribute the electric energy of a certain circui... -

Short Stress Rolling Mill

Short stress line rolling mill, also known as no archway rolling mill, is a kind of high stiffness rolling mill, which is used as section steel When the rolling mill is used, it should not only have high radial stiffness, but also have high Axial stiffness. At present, many types of short stress line mills have been developed in China, such as Gy Type, Hb type, CW type, sy type, GW type and DW type, among which there are three representative types It is Gy type short stress line rolling mill,... -

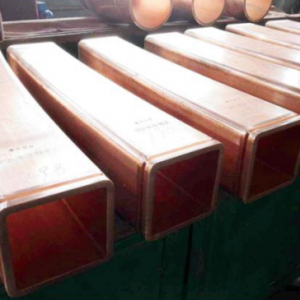

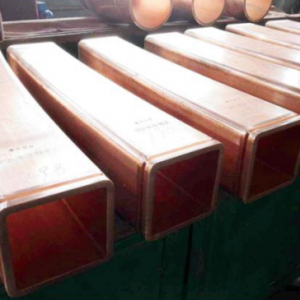

Mold Copper Tube-Crystallizer

Equipment for crystallization operation. There are many types of crystallizers, which can be divided into evaporation crystallizer and cooling crystallizer according to the method of obtaining supersaturation state of solution; According to the flow mode, it can be divided into mother liquor circulating crystallizer and crystal slurry (i.e. the mixture of mother liquor and crystal) circulating crystallizer; According to the operation mode, it can be divided into continuous crystallizer and in...