Products

-

Flying shears

Flying shear is a kind of equipment to implement the shearing process of rolled pieces in the movement of rolled pieces. It is one of the indispensable and key equipment in the continuous steel rolling production line. With the development of steel rolling process and the transformation needs of steel plant capacity expansion, higher requirements are put forward for steel rolling equipment, mainly reflected in large rolling section and high rolling speed. Main uses: flying shear is often used... -

flying shears

Flying shear is a kind of equipment to implement the shearing process of rolled pieces in the movement of rolled pieces. It is one of the indispensable and key equipment in the continuous steel rolling production line. With the development of steel rolling process and the transformation needs of steel plant capacity expansion, higher requirements are put forward for steel rolling equipment, mainly reflected in large rolling section and high rolling speed. Main uses: flying shear is often used... -

Continuous casting machine

Continuous casting machine production process. The high-temperature molten steel is continuously poured into one or a group of water-cooled copper crystallizers, and the molten steel is gradually solidified into a blank shell along the periphery of the crystallizer. After the steel liquid level rises to a certain height and the blank shell solidifies to a certain thickness, the tension leveler pulls out the blank, and the slab is cooled by water spraying in the secondary cooling area to compl... -

Induction coil of medium frequency furnace

Induction furnace is an electric furnace that uses the induction electric heating effect of materials to heat or melt materials. The AC power supply used for the induction furnace includes power frequency (50 or 60 Hz), medium frequency (150 ~ 10000 Hz) and high frequency (higher than 10000 Hz). The main components of induction furnace include inductor, furnace body, power supply, capacitor and control system. Under the action of alternating electromagnetic field in the induction furnace, edd... -

Intermediate frequency furnace

Aluminum shell furnace: simple structure. The service life is 5 to 8 years. It is applicable to the capacity of less than 2 tons. There is no guide magnet, furnace lining ejection mechanism, fire-resistant mastic layer, and the safety performance is poor. For example, when a set of 5-ton medium frequency furnace is full of molten iron, the overall weight of the equipment reaches 8 to 10 tons. If the aluminum shell structure is selected and the reducer rotates the furnace body to 95 degrees, t... -

mill roll

- Nature: it is an important part of the rolling mill in the rolling mill

- Composition: roll body, roll neck and shaft head

- Application: rolling mill

- Hardness:HSD58-80

- Size:φ280-800

- Maximum machining length:6000mm

- Product description: The roller is an important part of bai steel mill rolling machine. It USES the pressure generated by a pair of Du or a group of rollers to roll the steel. D It is mainly affected by static and static

-

Crank flying shear

The company’s production equipment is mainly used in rolling mills, the equipment can produce bar, wire, steel, strip steel, output from 10,000 tons/year to 500,000 tons/year: -

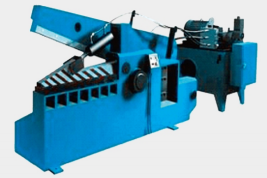

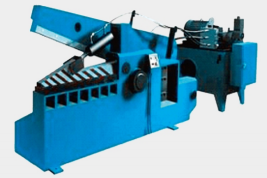

Crocodile scissors

- Model:50ton~500ton

- Cutting edge width:800~1500

- Material of shear blade:H13

- Motor power:5.5~35KW

- Product description: Crocodile shear is suitable for cold shear of various shapes of section steel and various metal structures in metal recovery companies, scrap steel factories and smelting and casting enterprises

-

mill roll

- Hardness:HSD58-80

- Size:φ280-800

- Maximum machining length:6000mm

- Product description: The roller is an important part of bai steel mill rolling machine. It USES the pressure generated by a pair of Du or a group of rollers to roll the steel. D It is mainly affected by static and static

-

Vertical rolling mill

- Model:250-650

- Size:φ280-800

- Billet size:60×60~250×250

- Motor power:130~1000KW

- Product description: Roughing mill for the production of various steels

-

Continuous Casting Machine

- Drawing speed:1.5m-4m/min

- Garden billet size:φ60~φ250

- Billet size:60×60~250×250

- Model:R3000~R8000

- Product description: Continuous casting machine production process. High temperature molten steel continuous casting to one or a set of water-cooled copper mold, steel along gradually solidified into a shell surrounding

-

Steel rolling equipment 01 (Rolling mill column)

Model:250-650

The material:High quality cast steel

mill roll diameter:φ280-700