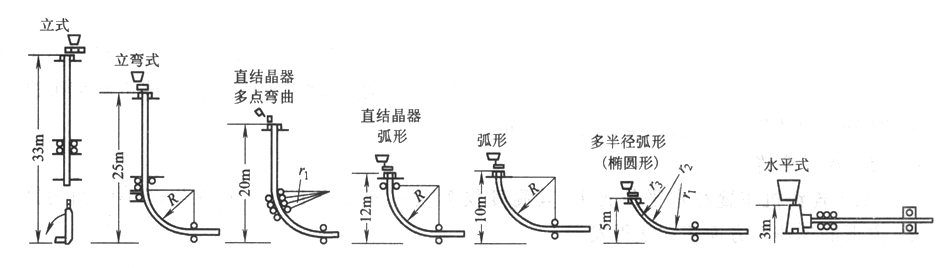

Vertical Continuous Casting Machine

Structural characteristics: The process equipment such as crystallizer, second cold and dense row of clamping section, billet drawing equipment and cut-to-length are arranged in vertical direction.

Advantages.

No bending straightening deformation, uniform cooling and less cracking.

Inclusions are easy to float.

Disadvantages.

High equipment and construction costs.

High static pressure of steel, easy to produce bulging.

Slow drawing speed, low production efficiency.

Scope of application.

High quality steel or oversized section. Such as high purity steel, high alloy steel, high S/P steel, etc.; extra thick slab, oversized round billet/billet.

Vertical bending type continuous casting machine

Structural features.

Vertical section under the crystallizer, bending and straightening (complete solidification of the steel), horizontal cutting.

Advantages.

Lower height of the machine body than vertical.

With vertical section, inclusions are easily floated and evenly distributed.

Horizontal billet, you can properly lengthen the body, the fixed size is not limited.

Disadvantages.

Small bending and straightening radius of cast billet, short interval, easy to form cracks.

Requires full solidification bending and straightening, which limits productivity.

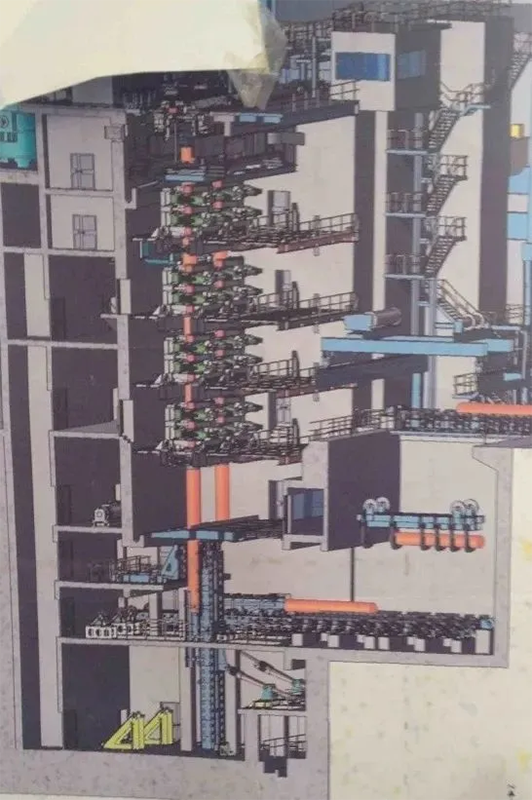

Straight arc continuous casting machine

Structural features: with vertical sections

Advantages.

Inclusions are easy to float, with the advantages of vertical bending continuous casting machine.

Multi-point bending, reducing stress concentration and less cracking.

Can enter the straightening horizontal section before complete solidification, which can increase the drawing speed and high productivity.

Scope of application: slab continuous casting

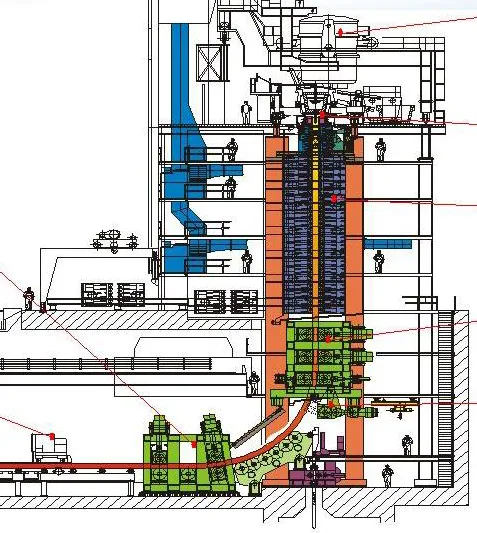

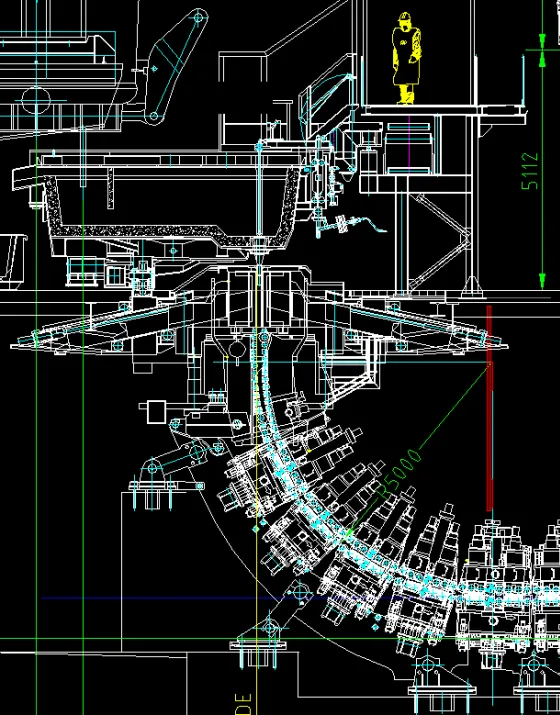

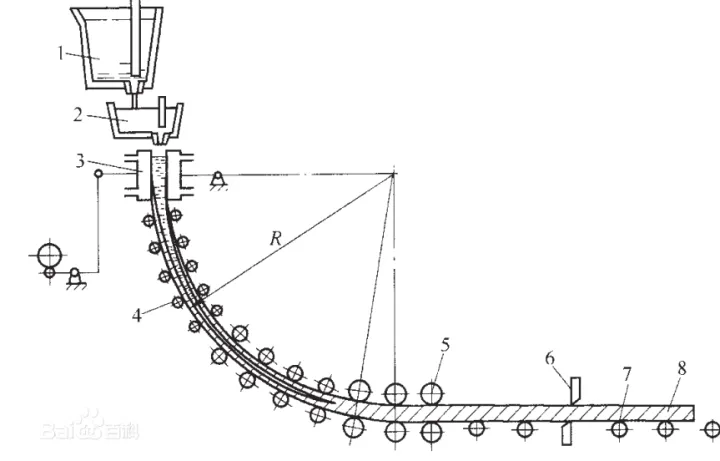

Full-arc continuous caster

Structural features.

Arc-shaped crystallizer

Advantages

Height of the machine body (1/2~1/3), low infrastructure cost.

Small static pressure of steel, easy control of drum belly.

High pulling speed and small flow number limitation.

Disadvantages.

Large machine and equipment footprint.

Inclusions in the inner arc are easy to collect.

Arc-shaped crystallizer processing is more complex

Scope of application: billet, round billet, shaped billet continuous casting

Horizontal Continuous Casting Machine

Advantages.

Low height, saving investment.

No bending straightening, good quality.

Disadvantages.

Aggregation of inclusions in the upper part.

Low drawing speed, low flow number, low output.

Ultra-low head continuous casting machine

Advantages.

Low body height and reduced plant height.

Low hydrostatic pressure of steel, low bulging of billet shell.

Disadvantages.

Inclusions cannot float up and separate, and the inner arc collects.

Multi-radius, the arc, installation, adjustment is difficult.

Currently the most widely used models: full-arc continuous casting machine, straight-arc continuous casting machine, vertical continuous casting machine.

Post time: Jan-12-2023