Industry News

-

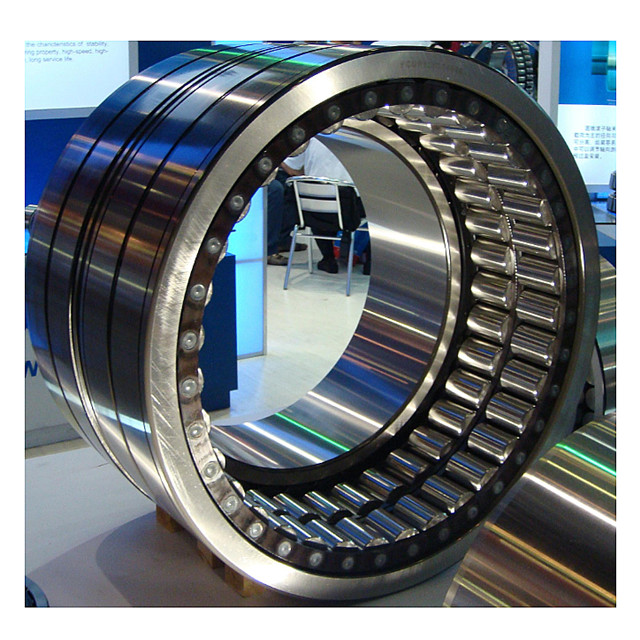

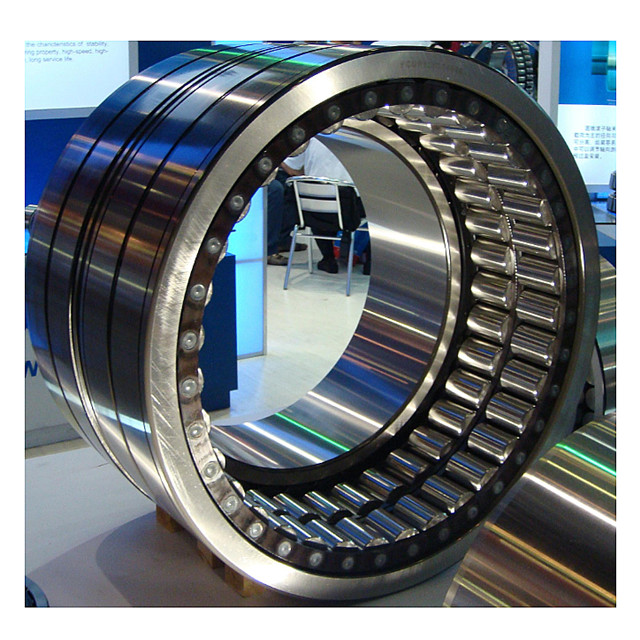

What Are The Causes Of Bearing Runout

Usually the bearing and the shaft are used together, the inner sleeve of the bearing is mounted with the shaft and the bearing jacket is mounted with the bearing housing. If the inner sleeve turns with the shaft, the inner sleeve adopts a close fit with the shaft and the bearing jacket adopts a c...Read more -

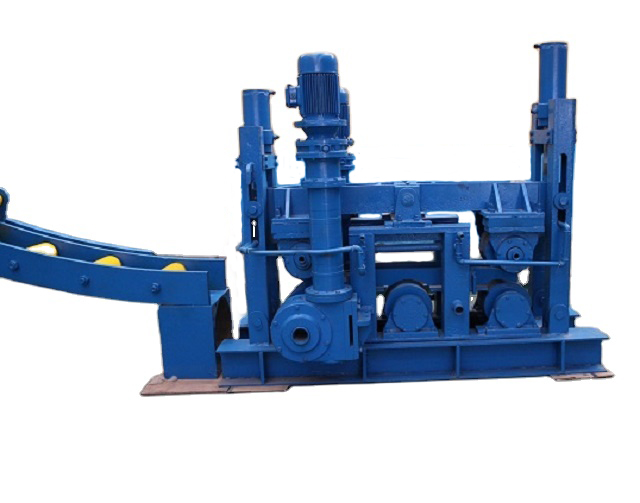

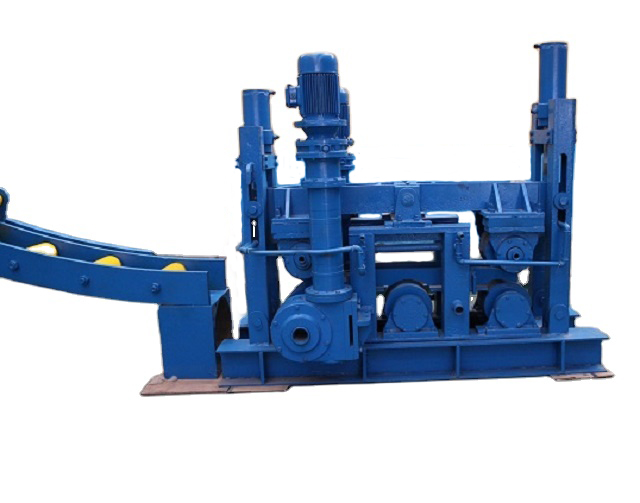

Slip Prevention And Control Measures For Tandem Cold Rolling Mill

Slip phenomenon occurs during the rolling process, that is, the relative sliding between the strip and the mill rolls, in essence, the deformation zone of the strip is completely replaced by the front or back slip zone. Slip phenomenon occurs lightly affect the surface quality and yield of the st...Read more -

Regular Maintenance And Care Of Steel Rolling Equipment

Enterprises should develop a rolling mill regular maintenance and maintenance system, but also to support the construction of routine maintenance and maintenance system, the specific content of the following aspects. 1. To regulate the daily operation of equipment users, assessment of their opera...Read more -

Y-2.jpg)

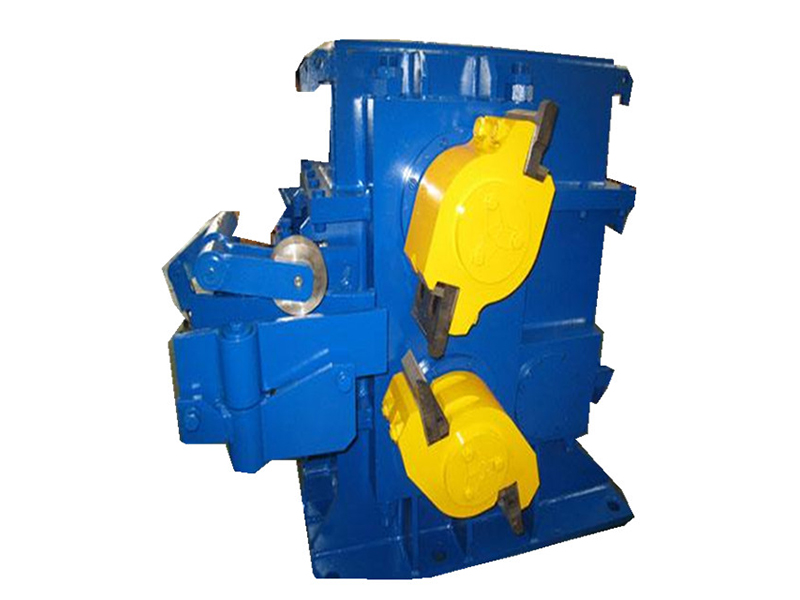

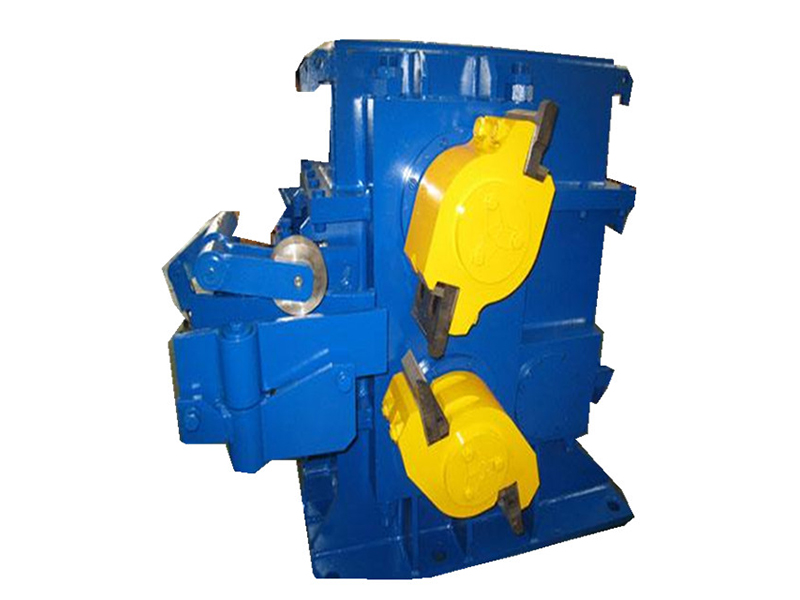

Maintenance and repair of rolled steel bar machinery and equipment

Steel rolling bar equipment has two parts: one is the main equipment; the other is the auxiliary equipment. The main equipment is responsible for the production of steel and plasticity and deformation work, also known as the main column of the rolling mill, its equipment contains the following ma...Read more -

Under What Circumstances Is A Fly Wheel Needed

Fly wheel rotates at high speed, which can store energy due to inertia, and also can release energy to overcome resistance to movement and make the engine run smoothly. When running at high speed, the flywheel can store energy and make it pick up speed slowly to avoid damage to other parts caused...Read more -

Build Up Welding

A welding method in which metal is melted by electric or gas welding and deposited on a tool or machine part. It is usually used to repair worn and chipped parts. Build up welding as an economical and rapid process method for surface modification of materials, resurfacing welding is increasingly ...Read more -

How to use aluminum melting furnace efficiency will be better?

With the development of the world economy, people’s demand for aluminum is growing, the development of science and technology is becoming more and more rapid, and products are constantly being introduced, according to the needs and development of enterprises themselves, the emergence of alu...Read more -

The Importance Of Lubricants For Steel Rolling Mills

For the daily operation of enterprises, machinery and equipment play an important role, only when the machinery and equipment running stable, to create good economic benefits for enterprises. In the rolling mill, the rolling mill plays a key role, but if there are problems with equipment lubricat...Read more -

Bar Rolling Flying Shear Should Be How To Choose?

Flying shear is generally based on the section of the mill and unit layout to choose, for the semi-continuous rolling line in the roughing mill after the choice of fixed shear, for continuous rolling line generally choose flying shear, in the continuous rolling off the head area can also choose f...Read more -

What Are The Characteristics Of Continuous Rolling Mills For Bar Rolling Process?

At present, China still has a small number of horizontal mini-rolling mills, there are also a few semi-continuous mini-rolling mills, but the vast majority are continuous mini-rolling mills. The characteristics of continuous rolling mills are. (1) continuous casting billet as raw material, a fir...Read more -

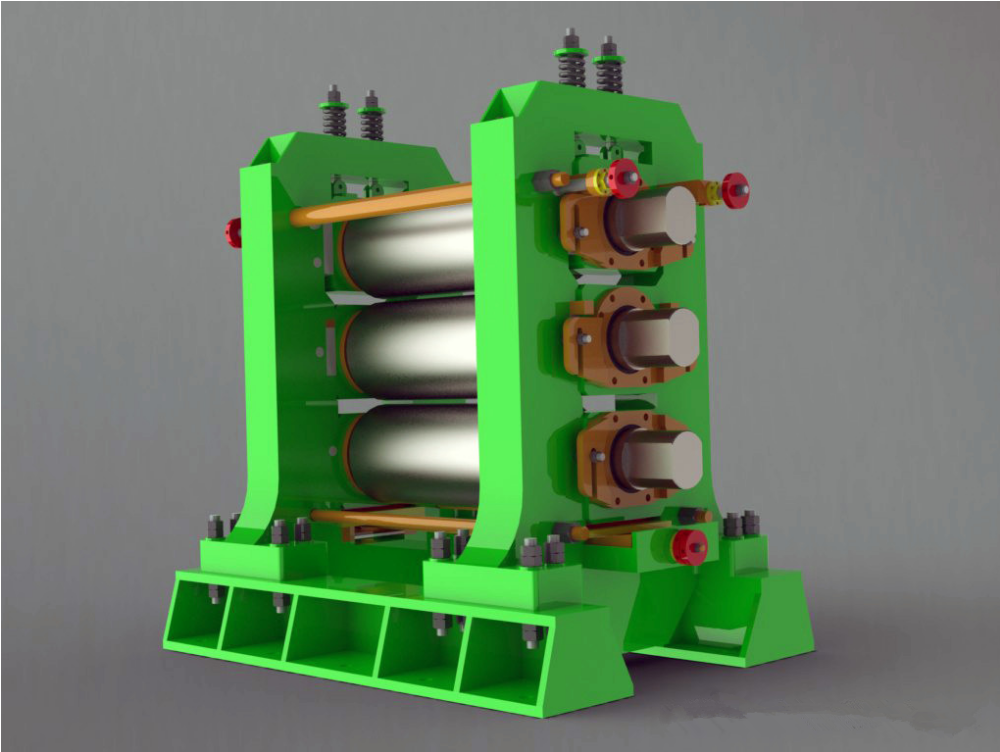

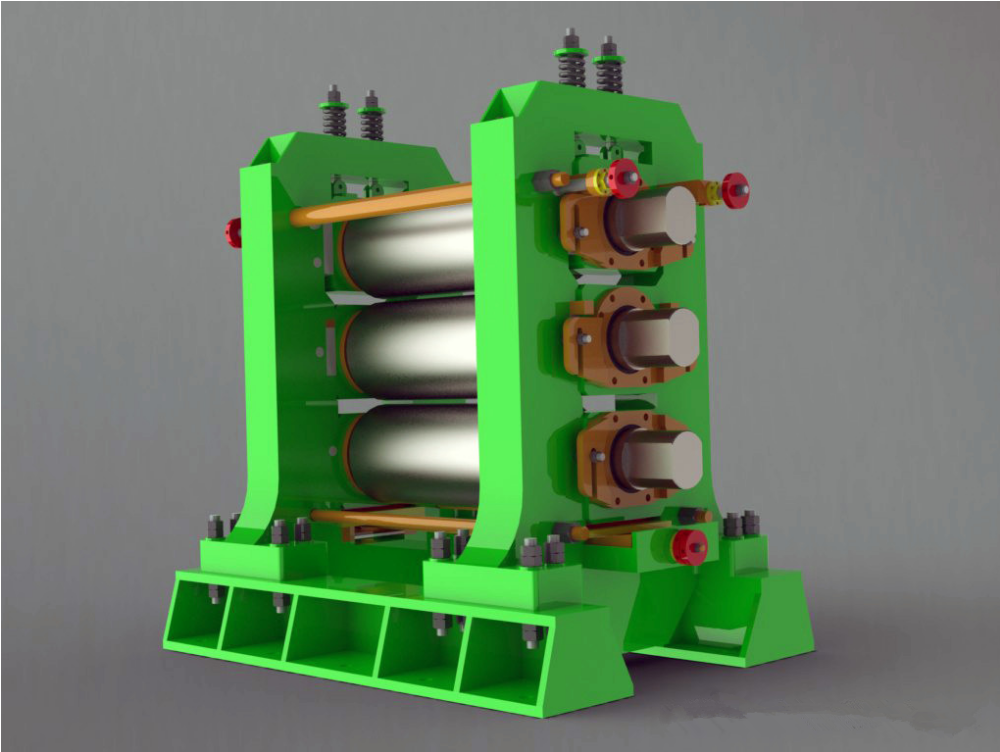

What Equipment Is Used In The Bar Rolling Process?

At present, most of the companies rolling high-strength steel bars use High rigidity rolling mill, which generally have relatively large rolling force energy parameters and rolling accuracy. Especially in recent years, the new bar and wire rod production lines, roughing and mid-rolling areas of H...Read more -

Aluminum Ash Slag Melting Furnace

1:The construction goal of the annual treatment of chemical Aluminum Melting Furnace. The aluminized ash smelter is a good solution to effectively utilize the aluminized ash and turn it into renewable energy. It can also help to reduce the land occupation and thus protect our natural resources. ...Read more

Y-2.jpg)