Products

-

High Speed Wire Plant Spitting Machine

High-speed wire rolling mill generally refers to the wire rod mill with the maximum rolling speed higher than 40m/s, which is a comprehensive product of metallurgical technology, electric control technology and machinery manufacturing technology.

-

Two-Roller And Three-Roller Steel Rolling Mill

Roll diameter:φ280-1300

Rolling temperature:Cold rolling, hot rolling

Rolling speed:2.4m/s-45m/s -

Medium Frequency Aluminum Shell Furnace

Smelting process:electromagnetic induction

Applicable site:Factory, plant, etc. -

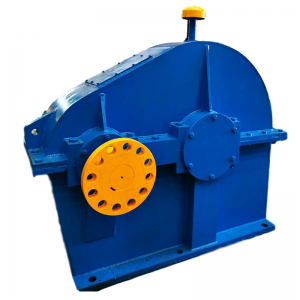

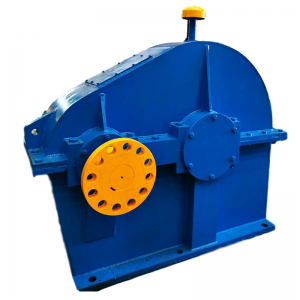

Horizontal High Precision Helical Gear Reducer

Applicable Materials: Copper Core, Cast Iron

Output Speed Range:20

-

Continuous Caster In Steel Making

Rolling temperature:>950℃

Motor power:2.2KW-50KW

-

High Quality Rolling Rebar Machine

Rolling Speed:2.4m/s-45m/s

Roll Width:350-2200

-

Industrial Steel Rolling Mills

A steel mill is a machine used to change the shape and size of steel materials by pressure, and the main body of the mill is a complete set of equipment for rolling and rolling metal billets into materials. The rolling mill is the main machine for rolling metal directly, it uses the rotating rolls to roll the billet to make the metal plastic deformation according to the specified requirements. Rolling is the highest productivity, the lowest cost metal forming method, suitable for rolling the ... -

Industrial Rolling Mill Rolls

Commonly used roll materials include alloy forged steel, alloy cast steel and cast iron. Alloy forged steel is used for the alloy forged steel of the mill roll. The roll is an important part of the rolling mill in the rolling mill. The pressure generated by a pair or a group of rolls is used to roll the steel. It is mainly subjected to dynamic and static loads, wear and temperature changes during rolling. The materials of the work rolls in the commonly used cold rolls are 9Cr, 9Cr2, 9Crv, 8C... -

Casting Intermediate Frequency Furnace

Foundry Intermediate Frequency Furnace is designed and manufactured for the foundry industry scrap metal melting and non-standard medium frequency heating equipment, the use of medium frequency electromagnetic heating principle to quickly melt scrap metal and metal scraps, belongs to the metal remelting category, add trace alloy composition to change the performance index of castings. A, Casting medium frequency furnace profile. 1、Melting metal material: steel, iron, alloy aluminum, alloy co... -

Tube Heating Furnace-Industrial Smelting Furnace

Tube heating furnace is a process heating furnace used in petroleum refining, petrochemical and chemical and chemical fiber industries, which has several features that are not found in other industrial smelting furnaces. Basic features: has a combustion chamber surrounded by refractory materials, using the heat generated by the combustion of fuel to heat the material of a device. Tube heating furnace characteristics. 1) The heated material flows inside the tube, so it is limited to heating ga... -

Industrial Rebar Rolling Mill

Since the 1980s, the development of section steel production equipment has been relatively slow compared to plate and strip mills. Although the rolling mill structure has been greatly improved, such as the development of cantilever CL mill, short stress line high stiffness HS mill, short stress line universal mill, etc., but no completely new type of rebar rolling mill, rolling speed is not much. The new development of section steel production equipment mainly lies in. (1) Continuous casting... -

Flying Shears For Bar Rolling

Product Name Flying Shears Definition Shear Running In The Lateral Shear Of The Rolled Parts Brand Runxiang Requirements Shear Edge Should Have The Best Shear Edge Clearance Industry Metallurgy Rolling Steel Equipment Components Flying Shear Body, Transmission Device, Etc. Horizontal shear running shear of rolling parts called flying shear, is a kind of processing equipment that can quickly cut off iron sheet, steel pipe, paper rolls, is the metallurgical rolling industry, high-s...