He ala kuʻikuʻi kahi e hoʻoheheʻe ʻia ai ka metala e ka wili uila a i ʻole ke kinoea a waiho ʻia ma kahi mea hana a i ʻole ʻāpana mīkini.Hoʻohana maʻamau ia no ka hoʻoponopono ʻana i nā ʻāpana ʻāwīwī.

Kukuluup welding ma ke ʻano he kaʻina hana wikiwiki no ka hoʻololi ʻana i ka ʻili o nā mea,re hoʻolele ʻia anawelding hoʻohana nui ʻia i ka hana ʻana a me ka hoʻoponopono ʻana i nā ʻāpana i nā ʻāpana ʻoihana like ʻole.I mea e hoʻohana maikaʻi loa ai i ka papa overlay, makemake ʻia e hoʻohana i kahi ʻano hoʻoheheʻe overlay me ka liʻiliʻi liʻiliʻi kumu kumu dilution, kiʻekiʻe deposition wikiwiki a me ka maikaʻi loa overlay papa hana, ʻo ia hoʻi, kahi kiʻekiʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe, haʻahaʻa haʻahaʻa overlay wiliwili ʻenehana. .

ʻO ka ʻenehana hoʻoheheʻe anuanu ka hoʻohana ʻana i ka loina hoʻokuʻu ʻana i ka uila uila kiʻekiʻe, ka mea hana me ka uhi ʻole ʻana o ka wela, e hoʻoponopono i nā hemahema o ka ʻili a me ka lole o ka mea hana metala, hiki ke hōʻoia i ka pono o ka mea hana;Hiki ke hoʻohana i kāna hana hoʻoikaika e hoʻoikaika i ka mea hana, e hoʻokō i ke kūpaʻa aahu, ke kūpaʻa wela, ka pale ʻana i ka corrosion, a me nā mea ʻē aʻe..Hiki iā ia ke hele i nā hoʻokolohua metallographic, tensile a me ka paʻakikī, aʻo ka hui pū ʻana o nā mea welding a me ka substrate e hōʻoia i ka paʻa o ka welding.Hoʻohana maʻamau ia no ka hoʻoponopono ʻana i nā pinholes, porosity, burrs, lele lele, bumps, scratches, chipped corners, collapsed corners, grit holes, cracks, abrasions, inclusions, manufacturing errors, manufacturing defects, welding defects and mechanical surface strengthening precision castings.

Ka hoʻoulu ʻanawelding nā noi

ʻO ka hana ʻana i ka poʻi

E hoʻonui i ka aesthetics a me ke ola lawelawe;ka mahiole i hoʻopololei ʻia ma luna o ka uhi ʻana o ka ʻili;alumini alumini make hoʻoheheʻe ʻia ʻana o ka hoʻokaʻawale ʻana i ka ʻili o ka cone hoʻoikaika;ʻAʻole maikaʻi loa, ʻaʻahu, nā ʻōpala a me nā hoʻoponopono hou a me ka hoʻoikaika ʻana.

ʻO ka paʻakai a me ka ʻōpala

Hoʻoponopono ʻia nā ʻāpana mīkini ʻōpala a me ka ʻili, ka ʻōpala, nā ʻāpana plastik me ka uhi ʻana o ka mold, ʻaʻahu a hoʻoponopono.

Aerospace

Nā ʻāpana ʻenekini mokulele, turbine, hoʻoponopono a hoʻoponopono hou paha, hoʻoponopono hou ʻana i ka ʻili o ka nozzle rocket, hoʻoponopono ʻana i nā ʻāpana o waho o ka mokulele, hoʻoikaika a hoʻoponopono ʻia paha nā ʻāpana satelite hana, nā ʻāpana titanium o ka hoʻoikaika ʻana i ka carburization kūloko. ka hoʻoikaika ʻana, ka carburization ili o ka magnesium A1 a me nā mea hoʻopili anti-corrosion ʻē aʻe, nā ʻāpana huila magnesium o ka hoʻoponopono ʻana i ka uhi ʻana o nā pōʻino kūloko, ka nickel-based / cobalt-based kiʻekiʻe-mehana pāhaʻi huila hana hoʻoponopono i uhi ʻia, e like me: ʻO ka ʻaʻahu a me ke alakaʻi ʻana i ka maka, etc.

Hoʻoponopono hana

ʻOihana kaʻa a me ka mālama ʻana, hoʻohana ʻia no ka cam, crankshaft, piston, cylinder, brake disc, impeller, wheel hub, clutch, friction plate, exhaust valve, etc. hoʻoponopono.

Mana moku

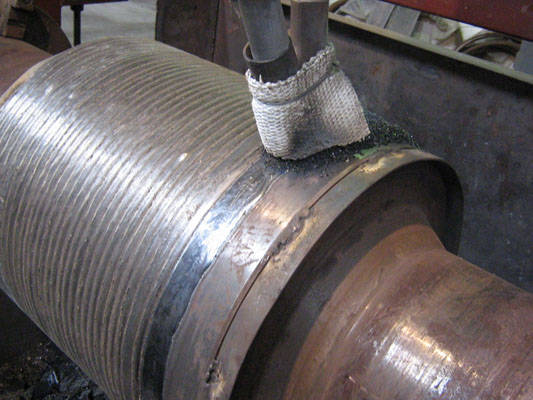

Uila crankshaft, bushings, shaft tiles, uila mea, resistors, etc. hooponopono, wiliwili o ka uila kaaahi huila a me lalo laina laina laina, electroplating mea kanu conductive roller, metala oxidation lapaʻau o ke keleawe a me ka alumini electrode hana kuʻihao.

ʻOihana mīkini

Kukuluup welding Hiki iā ia ke hoʻoponopono i ka mea hana me ka ʻokoʻa nui a me ka hoʻoponopono ʻana i ka mīkini paahana alakaʻi, nā ʻano like ʻole, nā cams, hydraulic press, hydraulic press plungers, cylinder walls, journals, rollers, gears, pulleys, arbors for spring forming, plug gauges, ring gauges, various rolls, koʻokoʻo, kolamu, loka, bearings, etc.

ʻOihana hoʻolei

Hoʻoponopono i nā hemahema e like me nā lua one a me nā lua ea i ka hao, ke keleawe a me ka aluminika, a me ka hoʻoponopono ʻana i ka lole a me nā waimaka o nā kumu hoʻohālike alumini.

Ka manawa hoʻouna: Nov-03-2022