Habka alxanka kaas oo birta lagu dhalaaliyo alxanka korontada ama gaaska oo lagu shubo qalab ama qayb mashiinka.Caadi ahaan waxa loo isticmaalaa in lagu hagaajiyo qaybaha xidhan iyo kuwa la jarjaray.

Dhisup welding sida habka dhaqaale iyo dhaqsaha badan ee wax ka beddelka alaabta,rsoo saaridwelding waxaa si isa soo taraysa loo isticmaalaa soo saarista iyo hagaajinta qaybo ka mid ah qaybaha warshadaha kala duwan.Si loo sameeyo isticmaalka ugu waxtarka badan ee lakabka daboolka ah, waxaa la rabaa in la isticmaalo habka alxanka dusha sare leh oo leh qasitaan walxeed oo yar, xawaare sare oo dhejis ah iyo waxqabadka lakabka sare ee aad u fiican, ie tayada sare, waxtarka sare, farsamada alxanka dufan yar. .

Tiknoolajiyada daboolka alxanka qabow waa isticmaalka mabda'a koronto-soo noqnoqda sare ee mabda'a dareeraha, shaqada iyada oo aan lahayn kulaylka, si loo hagaajiyo cilladaha dusha sare iyo xirashada birta birta, waxay xaqiijin kartaa daacadnimada shaqada;sidoo kale isticmaali kartaa ay shaqada xoojinta si ay u xoojiyaan workpiece ah, si ay u gaaraan caabbinta xirashada, iska caabin kulaylka, iska caabin daxalka, iwm.Waxay ka gudbi kartaa tijaabooyinka birta, adkaysiga iyo qallafsanaanta, halka isku-dhafka birta ee walxaha alxanka iyo substrate-ka ay hubinayaan adkaynta alxanka.Waxaa caadi ahaan loo isticmaalaa hagaajinta godad fiiqan, porosity, burrs, geesaha duulaya, kuuskuus, xagashada, geesaha jajaban, geesaha dumay, godadka jeexjeexan, dildilaaca, abrasions, ka mid ah, khaladaadka wax soo saarka, cilladaha wax soo saarka, ciladaha alxanka iyo xoojinta farsamada ee kabka saxda ah.

Dib u soo noolayntawelding codsiyada

Samaynta caaryada

Duubista caaryada caaga ah si kor loogu qaado bilicda iyo nolosha adeegga;koofiyada caagagga ah ee kala qaybinta dusha sare ee dayactirka;aluminium aluminium dhinta tuurista caaryada kala qaybsanaanta koorta korka xoojinta;dalool caaryada aad u liidata, xirashada, xagashada iyo hagaajinta iyo xoojinta kale.

Caag iyo caag

Mashiinnada caagga ah iyo qaybaha dayactirka, caag, qaybo caag ah oo leh caaryada isku dhejisan, xirashada iyo dayactirka.

Hawada hawada

Qaybaha mishiinka diyaaradda, marawaxadaha, dayactirka usheeda dhexe ama marawaxadaha, dayac-tirka dushiisa biibiile, dayactirka qaybaha saxanka dibadda diyaaradda, xoojinta qolofka dayax-gacmeedka macmalka ah ee xoojinta ama dayactirka, Qaybaha daawaha titanium ee xoojinta carburization maxalliga ah, qaybaha daawaha heerkulka-sare ee birta qaybaha carburization deegaanka xoojinta, Carburization alloy dusha magnesium A1 iyo daahan kale oo ka-hortagga daxalka, daahan magnesium qaybo ka mid ah cilladaha maxalliga ah dahaadh dayactirka, daab daabka ku salaysan heerkulka-ku-salaysan / cobalt workpiece dayactirka dahaadhka maxalliga ah, sida: daab madaxa damping dusha sare iyo caarada xidhashada daabka iyo hagid ka saaridda daabka, iwm.

Dayactirka wax soo saarka

Warshadaha wax soo saarka baabuurta iyo dayactirka, loo isticmaalo kamarad, crankshaft, piston, cylinder, disc brake, impeller, xarunta giraangiraha, xajin, saxan khilaafsan, valve qiiqa, iwm si loo sameeyo farqiga iyo dayactirka, dusha sare ee gaariga jirka alxanka cillad. dayactirid.

Awoodda markabka

Qalabka korantada ee korantada, bushings, foornada shafka, qaybaha korantada, iska caabinta, iwm. dayactirka, alxanka taayirrada tareenada korontada iyo qaybta hoose ee xadiidka tareenka, rullaluistemadka warshadda elektiroonigga ah, daaweynta oksaydhka birta ee naxaasta iyo alxanka soosaarka elektiroonigga aluminium.

Warshadaha mishiinada

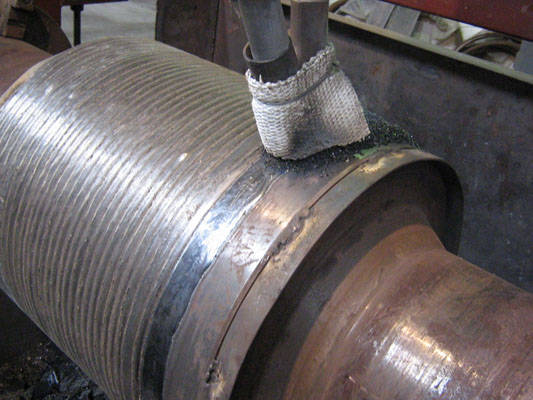

Dhisup welding hagaajin kartaa workpiece la kala duwanaansho xad-dhaaf ah iyo hagaha qalabka mashiinka dayactirka, ulihii kala duwan, kamaradaha, hydraulic presses, plungers haydarooliga, derbiyada dhululubo, joornaalada, rollers, marsho, jiidi, arbors for guga samaynta, fur cabbiraha, giraanta giraanta, duub kala duwan, ulaha, tiirarka, qufulka, biraha, iwm.

Warshadaha jilitaanka

Dayactirka cilladaha sida godadka ciidda iyo godadka hawada ee birta, naxaasta iyo aluminiumka shubka, iyo hagaajinta jeexjeexa iyo jeexjeexyada moodooyinka aluminiumka.

Waqtiga boostada: Nov-03-2022