Usoro ịgbado ọkụ nke a na-agbaze ọla site na ịgbado ọkụ eletrik ma ọ bụ gas ma tinye ya na ngwaọrụ ma ọ bụ akụkụ igwe.A na-ejikarị ya arụzi akụkụ ndị eyiri na ndị gbawara agbawa.

wuoup welding dị ka usoro akụ na ụba na ngwa ngwa maka ngbanwe elu nke ihe,rna-apụtawelding a na-ejiwanye ihe na-emepụta na nrụzi nke akụkụ dị iche iche nke ụlọ ọrụ mmepụta ihe.Iji mee ka ndị kasị dị irè ojiji nke machie oyi akwa, ọ na-chọrọ iji ihe machie ịgbado ọkụ usoro na nta isi ihe dilution, elu deposition ọsọ na magburu onwe machie oyi akwa arụmọrụ, ie a elu àgwà, elu arụmọrụ, ala dilution machie ịgbado ọkụ Usoro. .

Nkà na ụzụ ịgbado ọkụ oyi bụ iji ụkpụrụ mgbapụta ọkụ eletrik na-adị elu, ihe na-arụ ọrụ na-enweghị mkpuchi ọkụ, iji rụkwaa ntụpọ elu na iyi nke ọrụ igwe, nwere ike hụ na iguzosi ike n'ezi ihe nke workpiece;nwekwara ike iji ya ike ọrụ ike workpiece, iji nweta ndị na-eyi nguzogide, okpomọkụ na-eguzogide, corrosion eguzogide, wdg .. Cold ịgbado ọkụ machie ngwá adịghị deform, anneal, igbari elu ike na-eguzogide abrasion na metal workpiece mgbe mmezi.Ọ nwere ike ịgafe ule metallographic, tensile na ike siri ike, ebe nchikota metallurgical nke ihe ịgbado ọkụ na mkpụrụ na-eme ka ịgbado ọkụ siri ike.A na-ejikarị ya maka ịrụzi pinholes, porosity, burrs, na-efe efe n'ọnụ, kpụ ọkụ n'ọnụ, nkuku, nkuku chipped, nkuku dara ada, grit oghere, cracks, abrasions, inclusions, n'ichepụta njehie, n'ichepụta ntụpọ, ịgbado ọkụ ntụpọ na n'ibu elu ike nke nkedo ziri ezi.

Na-akpọlitewelding ngwa

Imepụta ebu

Plastic ebu elu burring na-abawanye aesthetics na ọrụ ndụ;okpu agha rọba ebu nkewa n'elu machie mmezi;aluminum alloy anwụ nkedo ebu nkewa cone elu ike;ebu oghere ibu ogbenye, eyi, scratches na ndị ọzọ mmezi na ike.

Plastic na roba

Nrụzi akụkụ igwe rọba na rọba, rọba, akụkụ plastik nwere ihe nkpuchi, eyi na ndozi.

Igwe ikuku

Akụkụ ụgbọ elu engine, turbine, turbine aro nrụzi ma ọ bụ rụkwaa, rọketi nozzle elu nrụzi, ụgbọ elu elu efere nrụzi, wuru satịlaịtị shei ike ma ọ bụ rụkwaa, titanium alloy akụkụ nke obodo carburization ike, ígwè dabeere elu-okpomọkụ alloy akụkụ nke obodo carburization. ike, magnesium alloy elu carburization A1 na ndị ọzọ mgbochi corrosion mkpuchi, magnesium alloy akụkụ nke mpaghara ntụpọ machie mmezi, nickel dabeere / cobalt dabeere elu okpomọkụ alloy agụba workpiece mpaghara machie mmezi, dị ka: agụba okpueze damping elu na n'ọnụ. nke uwe agụba na ntuziaka ablation agụba, wdg.

Nrụzi nrụpụta

Ụgbọ ala n'ichepụta na mmezi ụlọ ọrụ, eji maka cam, crankshaft, piston, cylinder, breeki diski, impeller, wheel hub, ipigide, esemokwu efere, iyuzucha valvụ, wdg ime ihe dị iche na ịrụzi, elu nke ụgbọ ala weld ntụpọ. rụkwaa.

Ike ụgbọ mmiri

Electric crankshaft, bushings, aro tiles, electric components, resistors, etc. mmezi, ịgbado ọkụ nke electric ụgbọ okporo ígwè wiil na ala akara njikọ ụgbọ okporo ígwè ibe, electroplating osisi conductive rola, metal oxidation ọgwụgwọ nke ọla kọpa na aluminum electrode mmepụta ịgbado ọkụ.

Ụlọ ọrụ igwe

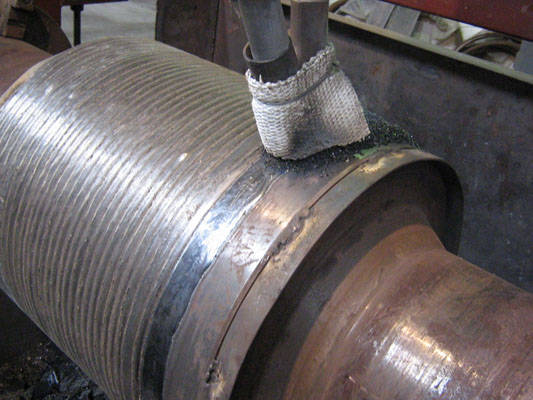

wuoup welding nwere ike dozie workpiece na oke ihe dị iche na nrụzi igwe ntuziaka ngwaọrụ, dị iche iche aro, cams, hydraulic press, hydraulic press plungers, cylinder mgbidi, akwụkwọ akụkọ, rollers, gia, pulleys, arbors maka mmiri akpụ, nkwụnye gauges, mgbanaka gauges, dị iche iche na-apụta, mkpara, ogidi, mkpọchi, bearings, wdg.

Ụlọ ọrụ nkedo

Ndozi ntụpọ dị ka oghere ájá na oghere ikuku na nkedo ígwè, ọla kọpa na aluminom, na nrụzi akwa na akwa nke ụdị aluminum.

Oge nzipu: Nov-03-2022