Nzira yekugadzira iyo simbi inonyungudutswa nemagetsi kana gasi welding uye inoiswa pane chishandiso kana muchina chikamu.Inowanzoshandiswa kugadzirisa dzakasakara uye dzakaputirwa zvikamu.

Vakaup welding senzira yehupfumi uye yekukurumidza nzira yekugadziriswa kwepasi kwezvinhu,resurfacingwelding iri kuwedzera kushandiswa mukugadzira nekugadzirisa zvikamu muzvikamu zvakasiyana-siyana zveindasitiri.Kuti unyatso shandisa iyo overlay layer, inodiwa kushandisa overlay welding nzira ine diki base material dilution, yakakwira deposition speed uye yakanakisa overlay layer performance, kureva yemhando yepamusoro, inoshanda zvakanyanya, yakaderera dilution overlay welding technique. .

Cold welding overlay tekinoroji iko kushandiswa kweyepamusoro-frequency electric spark discharge musimboti, iyo workpiece isina kupisa kwepamusoro, kugadzirisa kukanganiswa kwepamusoro uye kupfeka kwesimbi workpiece, inogona kuve nechokwadi chekuvimbika kweiyo workpiece;inogonawo kushandisa simba rayo rekusimbisa kusimbisa workpiece, kuti ibudirire kupfeka kupikisa, kupisa kwekushisa, kusagadzikana kwekuora, nezvimwewo.Inogona kupfuudza metallographic, tensile uye kuomarara bvunzo, nepo kusanganiswa kwemetallurgical ye welding zvinhu uye substrate inovimbisa kusimba kwewelding.Inowanzoshandiswa kugadzirisa pinholes, porosity, burrs, flying edges, bumps, scratches, makona akaputsika, makona akaputsika, grit holes, kuputika, abrasions, inclusions, zvikanganiso zvekugadzira, kukanganisa kwekugadzira, kukanganisa kwehuputi uye kusimbiswa kwe mechanical surface ye precision castings.

Resurfacingwelding applications

Kugadzira mold

Plastiki mold pamusoro pekuputira kuwedzera aesthetics uye hupenyu hwebasa;ngowani yepurasitiki mold parting surface overlay kugadzirisa;aluminium alloy die casting mold parting cone surface kusimbisa;mold cavity super urombo, kupfeka, mavanga uye kumwe kugadzirisa nekusimbisa.

Plastiki uye rabha

Rubber uye epurasitiki muchina zvikamu kugadzirisa, rabha, epurasitiki zvikamu zvine mold kupindirana, kupfeka uye kugadzirisa.

Aerospace

Zvikamu zveinjini yendege, turbine, turbine shaft kugadzirisa kana kugadzirisa, rocket nozzle surface kusimbisa kugadzirisa, ndege yekunze kweplate parts kugadzirisa, artificial satellite shell kusimbisa kana kugadzirisa, titanium alloy zvikamu zvekusimbisa carburization, iron-based high-temperature alloy parts of local carburization. kusimbisa, magnesium alloy pamusoro carburization A1 uye mamwe anti-corrosion coating, magnesium alloy zvikamu zvenzvimbo yakakanganisika pamusoro pekugadzirisa, nickel-based / cobalt-yakavakirwa yakakwira-tembiricha alloy blade workpiece yenzvimbo yakavharidzirwa kugadzirisa, senge: blade korona inonyorovesa pamusoro uye muromo. yekupfeka kweblade uye kutungamira blade ablation, nezvimwe.

Kugadziriswa kwekugadzira

Indasitiri yekugadzira nekugadzirisa mota, inoshandiswa cam, crankshaft, piston, silinda, brake disc, impeller, wheel hub, clutch, friction plate, exhaust valve, nezvimwe kugadzira mutsauko uye kugadzirisa, pamusoro pemotokari yemuviri weld chirema. repair.

Simba rechikepe

Electric crankshaft, bushings, shaft tiles, zvinhu zvemagetsi, resistors, etc. kugadzirisa, welding yemagetsi njanji mavhiri uye yezasi line njanji yekubatanidza chidimbu, electroplating plant conductive roller, simbi oxidation kurapwa kwemhangura uye aluminium electrode kugadzira welding.

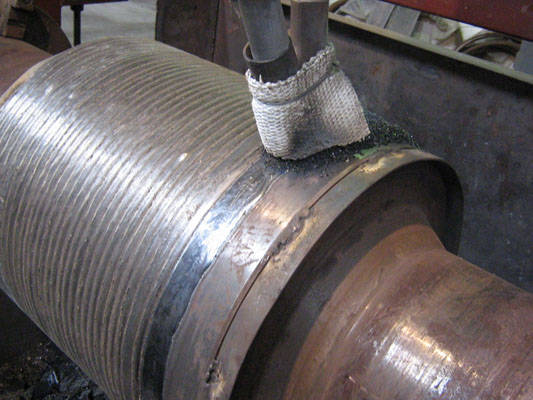

Michina indasitiri

Vakaup welding inogona kururamisa workpiece ine misiyano yakawandisa uye kugadzirisa muchina wedhizaini, akasiyana shafts, makamera, hydraulic press, hydraulic press plunger, cylinder madziro, majenari, rollers, magiya, pulleys, arbors ekugadzira chitubu, plug geji, mhete gauges, akasiyana rolls, tsvimbo, mbiru, zvivharo, mabhengi, nezvimwewo.

Casting industry

Kugadziriswa kwezvakaremara senge maburi ejecha uye maburi emhepo musimbi, mhangura uye aluminium castings, uye kugadziriswa kwekupfeka uye kubvaruka kwemhando dzealuminium.

Nguva yekutumira: Nov-03-2022