Indlela ye-welding apho isinyithi inyibilika ngombane okanye i-gas welding kwaye ifakwe kwisixhobo okanye inxalenye yomatshini.Ngokuqhelekileyo isetyenziselwa ukulungisa iindawo ezigugileyo kunye neziqhekekileyo.

Yakhaup welding njengendlela yoqoqosho kunye nenkqubo ekhawulezayo yokuguqulwa komphezulu wezinto eziphathekayo,rukuvelawelding isetyenziswa kakhulu ekwenzeni nasekulungiseni iinxalenye kumacandelo ahlukeneyo oshishino.Ukuze wenze olona setyenziso lusebenzayo lomaleko ongaphezulu, kunqweneleka ukusebenzisa indlela yokwaleka kwewelding enesiseko esincinci sokuxutywa kwemathiriyeli, isantya esiphezulu sokubekwa kunye nokusebenza okugqwesileyo komgangatho, oko kukuthi umgangatho ophezulu, ukusebenza kakuhle okuphezulu, ubuchule bokuwelda bokwaleka okuphantsi. .

Itekhnoloji yokwaleka kwe-welding ebandayo kukusetyenziswa komgaqo wokukhutshwa kwentlantsi yombane, i-workpiece ngaphandle kokugquma ubushushu, ukulungisa iziphene zomphezulu kunye nokunxiba kwentsimbi, inokuqinisekisa ingqibelelo yomsebenzi;inokusebenzisa umsebenzi wayo wokuqinisa ukuqinisa i-workpiece, ukufezekisa ukuxhathisa ukunxiba, ukumelana nobushushu, ukuxhathisa ukubola, njl.Iyakwazi ukudlula iimvavanyo ze-metallographic, i-tensile kunye nobulukhuni, ngelixa i-metallurgical indibaniselwano ye-welding material kunye ne-substrate iqinisekisa ukuqina kwe-welding.Ngokuqhelekileyo isetyenziselwa ukulungisa i-pinholes, i-porosity, i-burrs, i-flying edges, i-edges, i-scratches, iikona eziqhekekileyo, iikona ezidilikileyo, i-grit holes, ii-cracks, i-abrasions, inclusions, iimpazamo zokuvelisa, iziphene zokuvelisa, iziphene ze-welding kunye nokuqiniswa komphezulu womatshini wokuchithwa okuchanekileyo.

Ukuphinda umphezuluwelding izicelo

Ukwenziwa komngundo

Ukuvutha komphezulu wePlastiki ukunyusa ubuhle kunye nobomi benkonzo;isigcina-ntloko seplastiki ngundo esahlulayo sokwaleka ukulungiswa kobuso;ialluminiyam ialloy die casting mold partition cone ukomeleza umphezulu;Umgodi wokungunda umbi kakhulu, ukunxiba, imikrwelo kunye nokunye ukulungiswa nokomeleza.

Iplastiki kunye nerabha

Irabha kunye nezixhobo zoomatshini beplastiki ukulungiswa, irabha, iinxalenye zeplastiki ezinobumbano, ukunxiba kunye nokulungiswa.

I-Aerospace

Iindawo ze-injini yenqwelomoya, i-iturbine, ukulungiswa okanye ukulungiswa kweshafti ye-iturbine, ukulungiswa komphezulu we-rocket nozzle, ukulungiswa kwamalungu epleyiti yangaphandle yenqwelomoya, ukomeleza okanye ukulungiswa kweqokobhe lesathelayithi eyenziweyo, iindawo ze-titanium alloy zokuqinisa i-carburization yendawo, i-iron-based high-temperature alloy parts of local carburization. ukomeleza, i-magnesium alloy surface carburization i-A1 kunye nezinye izinto zokunqanda ukubola, i-magnesium alloy alloy iindawo zokulungiswa kokwaleka kwasekhaya, i-nickel-based / i-cobalt-based based high-temperature alloy blade workpiece ukulungiswa kwendawo engaphezulu, enje: yokukhutshwa kweblade kunye nokuchithwa kweblade, njl.

Ukulungiswa kwemveliso

Imveliso yemoto kunye nokugcinwa kwemoto, esetyenziselwa ikhamera, i-crankshaft, i-piston, i-cylinder, i-brake disc, i-impeller, i-wheel hub, i-clutch, i-friction plate, i-valve yokukhupha, njl. ukulungisa.

Amandla enqanawa

I-crankshaft yombane, i-bushings, i-shaft tiles, izakhi zombane, i-resistors, njl. njl. ukulungiswa, i-welding yamavili ombane kaloliwe kunye neqhekeza lokudibanisa umzila kaloliwe, i-electroplating plant conductive roller, unyango lwe-oxidation yensimbi yobhedu kunye ne-aluminium yokuvelisa i-electrode.

Ishishini loomatshini

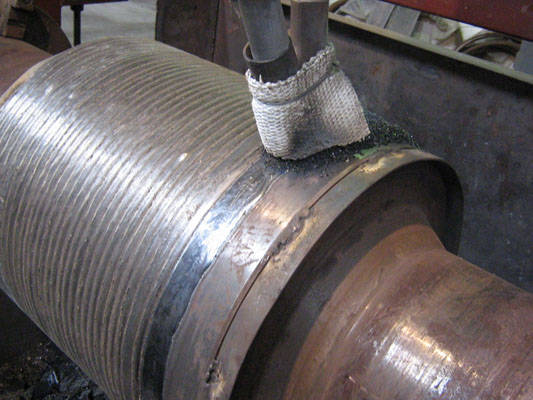

Yakhaup welding inokulungisa i-workpiece enomahluko ogqithisileyo kunye nesikhokelo somatshini wokulungisa izixhobo, iishafti ezahlukeneyo, iikam, i-hydraulic press, i-hydraulic press plunger, iindonga zesilinda, iijenali, iirola, iigiya, iipuli, ii-arbor zokwenza intwasahlobo, iigeji zeplagi, iigeji zeringi, imiqulu eyahlukeneyo, iintonga, iintsika, izitshixo, iibheringi, njl.

Ishishini lokuphosa

Ukulungiswa kweziphene ezifana nemingxuma yesanti kunye nemingxuma yomoya kwintsimbi, ubhedu kunye ne-aluminium castings, kunye nokulungiswa kokugqoka kunye nokukrazula kweemodeli ze-aluminium.

Ixesha lokuposa: Nov-03-2022