Mokhoa oa ho tjheseletsa oo tšepe e qhibilihang ka motlakase kapa khase ebe e kenngoa holim'a sesebelisoa kapa karolo ea mochini.Hangata e sebelisetsoa ho lokisa likarolo tse tsoileng matsoho le tse khaotsoeng.

Hahaup welding e le mokhoa oa moruo le o potlakileng oa ho fetola lisebelisoa tsa bokaholimo,re sufangwelding e sebelisoa ka ho eketsehileng ho etseng le ho lokisoeng ha likarolo makaleng a fapaneng a indasteri.E le hore u sebelise ka mokhoa o atlehang ka ho fetisisa oa lera le holimo, ho lakatseha ho sebelisa mokhoa oa ho tjheseletsa oa overlay o nang le dilution e nyenyane ea lisebelisoa tsa motheo, lebelo le phahameng la deposition le ts'ebetso e babatsehang ea lera, ke hore, boleng bo phahameng, bo sebetsang hantle, mokhoa o tlaase oa dilution overlay overlay. .

Cold tjheseletsa overlay thekenoloji ke tshebediso ya phahameng-frequency spark motlakase molao-motheo oa discharge, workpiece ntle mocheso overover, ho lokisa mefokolo holim'a le ho roala ha tšepe workpiece, ka etsa bonnete ba hore botšepehi ba workpiece;e ka boela ea sebelisa matla a eona a ts'ebetso ho matlafatsa workpiece, ho finyella ho hanyetsa ho roala, ho hanyetsa mocheso, ho hanyetsa kutu, joalo-joalo. Cold tjheseletsa sekoahelo thepa ha e deform, anneal, qhala matla a phahameng le ho hanela abrasion ho workpiece tšepe ka mor'a ho lokisoa.E ka fetisa liteko tsa metallographic, tensile le boima, ha motsoako oa metallurgic oa thepa ea ho tjheseletsa le substrate e tiisa ho tiea ha tjheseletsa.E atisa ho sebelisoa bakeng sa ho lokisa li-pinholes, porosity, burrs, flying edges, bumps, scratches, likhutlo tse robehileng, likhutlo tse oeleng, li-grit holes, mapetsong, li-abrasions, inclusions, liphoso tsa tlhahiso, liphoso tsa ho etsa thepa, liphoso tsa ho tjheseletsa le ho matlafatsa holim'a metsi ka mokhoa o nepahetseng.

Ho hlabollawelding lits'ebetso

Ho etsa hlobo

Ho chesoa ha hlobo ea polasetiki ho eketsa botle le bophelo ba ts'ebeletso;helmete polasetiki hlobo karohano holim'a holim'a tokiso;aluminium motsoako shoela ho lahla hlobo karohano khoune holim matlafatsa;hlobo cavity super futsanehile, ho apara, mengoapo le tse ling tse lokisa le ho matlafatsa.

Plastiki le rabara

Ho lokisa likarolo tsa mochini oa rabara le oa polasetiki, rabara, likarolo tsa polasetiki tse kopantsoeng ka hlobo, ho roala le ho lokisoa.

Sepakapaka

Likarolo tsa enjene ea sefofane, turbine, turbine shaft tokiso kapa tokiso, tokiso e matlafatsang holim'a rocket nozzle, ho lokisa likarolo tsa sefofane sa kantle, ho matlafatsa kapa ho lokisoa ha khetla ea satellite, likarolo tsa titanium alloy ea ho matlafatsa carburization ea lehae, likarolo tsa tšepe tse nang le mocheso o phahameng oa mocheso oa carburization ea lehae. matlafatso, magnesium alloy surface carburization A1 le tse ling tse anti-corrosion barbotage, magnesium alloy alloy likarolo tsa sebaka sa ho lokisoa ha likoli, nickel-based / cobalt-based high-themperature alloy blade workpiece tokiso ea sebaka sa lehae, joalo ka: ho tlosoa ha blade le ho tlosoa ha lehare, joalo-joalo.

Tokiso ea tlhahiso

Indasteri ea tlhahiso le tlhokomelo ea likoloi, e sebelisetsoang cam, crankshaft, piston, cylinder, brake disc, impeller, hub ea mabili, clutch, friction plate, exhaust valve, joalo-joalo ho etsa phapang le ho lokisa, bokaholimo ba 'mele oa koloi lokisa.

Matla a sekepe

Motlakase oa crankshaft, bushings, shaft tiles, likarolo tsa motlakase, li-resistors, joalo-joalo, ho lokisoa ha mabili a terene ea motlakase le sekotoana sa khokahano ea terene, electroplating plant conductive roller, phekolo ea tšepe ea oxidation ea koporo le aluminium electrode production welding.

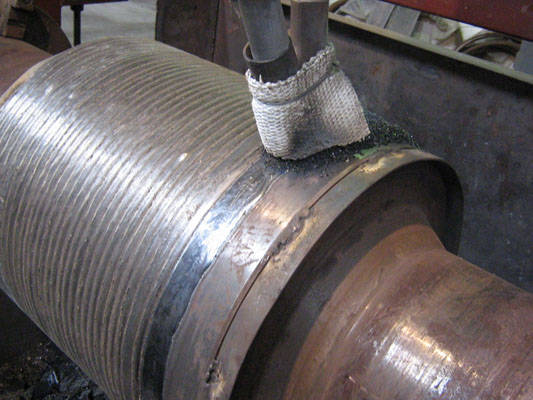

Indasteri ea mechine

Hahaup welding e ka lokisa sesebelisoa ka phapang e feteletseng le tataiso ea lisebelisoa tsa mochini, li-shafts tse fapaneng, lik'hamera, mochini oa khatiso oa hydraulic, li-plunger tsa hydraulic press, marako a silindara, likoranta, li-roller, likere, li-pulleys, li-arbor bakeng sa ho etsa selemo, li-plug gauges, li-ring gauges, meqolo e fapaneng, melamu, litšiea, liloko, li-bearing, joalo-joalo.

Indasteri ea ho lahla

Ho lokisoa ha mefokolo e kang masoba a lehlabathe le masoba a moea ka tšepe, koporo le aluminium castings, le ho lokisa ho senyeha ha mefuta ea aluminium.

Nako ea poso: Nov-03-2022