News

-

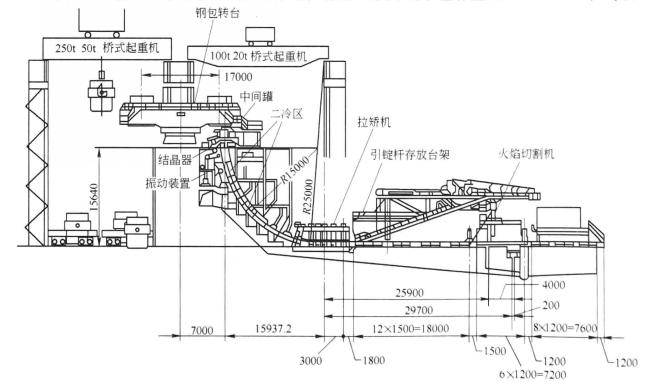

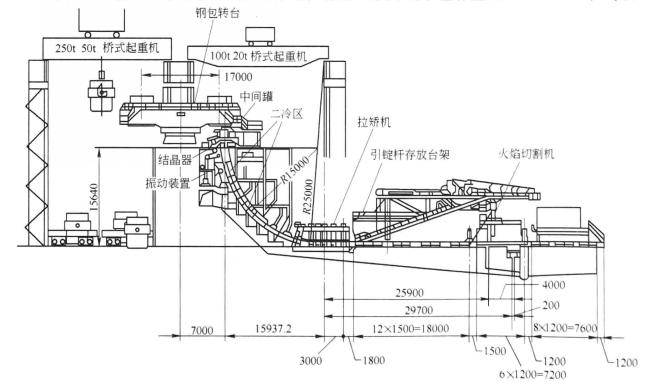

Composition of continuous casting machine

Generally, the continuous caster is composed of liquid steel carrier (ladle and rotary table), tundish and its replacement device, crystallizer and its vibration device, secondary cooling zone clamping roller and cooling water system, drawing straightener, cutting equipment, ingot drawing device,...Read more -

On the difference between steel shell furnace and aluminum shell furnace

On the difference between steel shell furnace and aluminum shell furnace 1. The service life of steel shell furnace is long, more than 10 years. The magnetic conductivity is good, and the steel shell furnace is 3-5% higher than the aluminum shell furnace The pouring point is stable, and the pouri...Read more -

Flying shear

The shearing machine of rolled piece in horizontal shearing operation is called flying shear. It is a processing equipment that can quickly cut off iron plate, steel pipe and paper coil. It is a fixed length shearing machine for metallurgical steel rolling industry, high-speed wire rod and thre...Read more -

Summarize the advantages and basic characteristics of cold rolling mill

A cold rolling mill is a machine that uses pressure to process metal materials. The cold rolling mill uses a motor to drag the steel bar, and the load-bearing roll and the work roll of the cold rolling mill jointly apply force to the two sides of the steel bar. It is a new type of steel cold roll...Read more -

What should be paid attention to during the shutdown of the rolling mill

In the production process of the rolling mill, when there is a failure to stop for maintenance or when it needs to be shut down in an emergency, what should be paid attention to after the rolling mill is stopped? Today, I will share with you a brief analysis. 1. After the rolling mill stops, stop...Read more -

Exhaust gas purification technology of steel rolling engineering

Steel rolling products are a variety of products, and different treatment processes will produce harmful waste gas causing environmental pollution, which not only cause harm to human health, but also cause bad effects on the quality of equipment and products.However, bef...Read more -

Working characteristics and classification of the rollers

The roll is a rolling production process by the friction force formed between the rolling roll into the rolling joint and causes compression to produce plastic deformation.The purpose of the rolling is to give the rolled material a certain shape, size, and performance.Th...Read more -

Strictly implement the management and maintenance of steel rolling machinery and equipment

The rapid development of the industrial field has brought more and more machinery and equipment into the field of steel. In recent years, the continuous application of modern science and technology in the industrial field has greatly improved the level of industrial mech...Read more