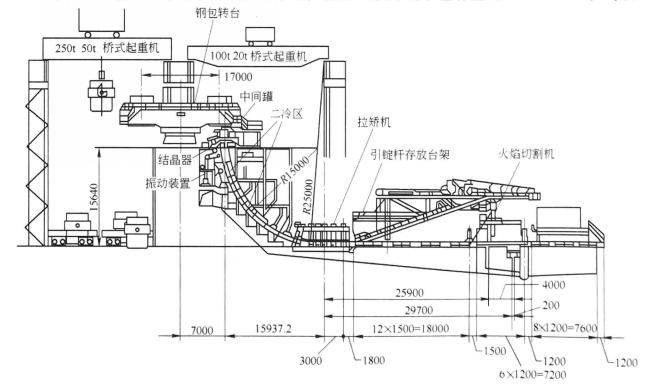

Generally, the continuous caster is composed of liquid steel carrier (ladle and rotary table), tundish and its replacement device, crystallizer and its vibration device, secondary cooling zone clamping roller and cooling water system, drawing straightener, cutting equipment, ingot drawing device, etc. (as shown in the figure below). Tundish plays the role of buffering and purifying molten steel. The capacity is generally 20% ~ 40% of the capacity of molten steel ladle. The more caster flow, the greater its capacity. The mold is the “heart” of the continuous casting machine, which requires good thermal conductivity, structural rigidity, wear resistance and easy manufacturing and maintenance. It is generally made of forged red copper or cast brass, and its outer wall is forced to be cooled evenly by water. The function of the mold vibration device is to make the mold vibrate periodically to prevent the bonding between the primary shell and the mold wall from being broken. The vibration curve generally changes according to the sinusoidal law to reduce the impact. Its amplitude and frequency should be closely matched with the drawing speed to ensure the quality and output of the billet. The secondary cooling device is installed immediately at the outlet of the mold. Its function is to accelerate the solidification of the slab and control the temperature of the slab by means of water spray or atomization cooling. The pinch roll and guide roll support the high-temperature slab with liquid core to prevent bulging deformation or internal crack. At the same time, the liquid core reduction technology can be carried out in this section to improve the slab quality and output. The water pressure and water volume of the secondary cooling device are required to be adjustable to meet the needs of different steel types and different drawing speeds. The function of the tension leveler is to provide the billet drawing power and straighten the bent billet, and promote the movement of the cutting device. The billet drawing speed has a great impact on the output and quality of continuous casting. The function of the ingot guiding device is to block the lower opening of the mold with the ingot guiding head before continuous casting, pull the billet out of the caster after the molten steel solidifies, disconnect the ingot guiding head, and put the ingot guiding rod into the storage device. The billet cutting equipment cuts the billet in continuous motion into fixed length. The commonly used cutting equipment are flame cutter or hydraulic shear and swing shear.

Generally, the continuous caster is composed of liquid steel carrier (ladle and rotary table), tundish and its replacement device, crystallizer and its vibration device, secondary cooling zone clamping roller and cooling water system, drawing straightener, cutting equipment, ingot drawing device, etc. (as shown in the figure below). Tundish plays the role of buffering and purifying molten steel. The capacity is generally 20% ~ 40% of the capacity of molten steel ladle. The more caster flow, the greater its capacity. The mold is the “heart” of the continuous casting machine, which requires good thermal conductivity, structural rigidity, wear resistance and easy manufacturing and maintenance. It is generally made of forged red copper or cast brass, and its outer wall is forced to be cooled evenly by water. The function of the mold vibration device is to make the mold vibrate periodically to prevent the bonding between the primary shell and the mold wall from being broken. The vibration curve generally changes according to the sinusoidal law to reduce the impact. Its amplitude and frequency should be closely matched with the drawing speed to ensure the quality and output of the billet. The secondary cooling device is installed immediately at the outlet of the mold. Its function is to accelerate the solidification of the slab and control the temperature of the slab by means of water spray or atomization cooling. The pinch roll and guide roll support the high-temperature slab with liquid core to prevent bulging deformation or internal crack. At the same time, the liquid core reduction technology can be carried out in this section to improve the slab quality and output. The water pressure and water volume of the secondary cooling device are required to be adjustable to meet the needs of different steel types and different drawing speeds. The function of the tension leveler is to provide the billet drawing power and straighten the bent billet, and promote the movement of the cutting device. The billet drawing speed has a great impact on the output and quality of continuous casting. The function of the ingot guiding device is to block the lower opening of the mold with the ingot guiding head before continuous casting, pull the billet out of the caster after the molten steel solidifies, disconnect the ingot guiding head, and put the ingot guiding rod into the storage device. The billet cutting equipment cuts the billet in continuous motion into fixed length. The commonly used cutting equipment are flame cutter or hydraulic shear and swing shear.

The actual length from the mold liquid level to the last pair of tension straightening rollers is the length of the caster, which should be 1.1-1.2 times the metallurgical length of the caster.

Post time: Apr-05-2022