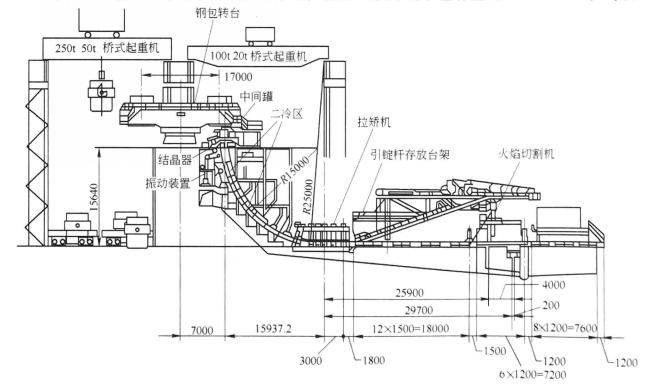

Ngokuvamile, i-caster okuqhubekayoyakhiwe ngesithwali sensimbi esiwuketshezi (i-ladle netafula elijikelezayo), i-tundish kanye nomshini wayo oshintshayo, icrystallizer kanye nedivayisi yayo yokudlidliza, i-cooling zone yesibili yokupholisa i-clamping roller kanye nesistimu yamanzi okupholisa, okokuqondisa ukudweba, okokusika, idivayisi yokudweba ingot, njll. (njengoba kubonisiwe emfanekisweni ongezansi).I-Tundish idlala indima yokubhafa kanye nokuhlanza insimbi encibilikisiwe.Umthamo ngokuvamile u-20% ~ 40% womthamo we-ladle yensimbi encibilikisiwe.Ukugeleza kwe-caster ngaphezulu, amandla ayo amakhulu.Isikhunta "inhliziyo" yomshini wokuphonsa oqhubekayo, odinga ukuqhutshwa okuhle kokushisa, ukuqina kwesakhiwo, ukumelana nokugqoka kanye nokukhiqiza nokugcinwa okulula.Ngokuvamile yenziwe ngethusi elibomvu elibunjiwe noma ithusi elicijile, futhi udonga lwayo lwangaphandle luphoqeleka ukuba lupholiswe ngokulinganayo ngamanzi.Umsebenzi wedivayisi yokudlidliza isikhunta ukwenza isikhunta sidlidlize ngezikhathi ezithile ukuvimbela ukubopha phakathi kwegobolondo eliyinhloko nodonga lwesikhunta ukuthi lungaphulwa.Ijika lokudlidliza ngokuvamile liyashintsha ngokuvumelana nomthetho we-sinusoidal ukunciphisa umthelela.I-amplitude yayo kanye nemvamisa kufanele ihambisane eduze nesivinini sokudweba ukuze kuqinisekiswe ikhwalithi nokuphuma kwe-billet.Umshini wokupholisa wesibili ufakwa ngokushesha lapho kuphuma isikhunta.Umsebenzi wayo ukusheshisa ukuqiniswa kwe-slab nokulawula izinga lokushisa le-slab ngokusebenzisa isifutho samanzi noma ukupholisa i-atomization.I-pinch roll kanye ne-guide roll isekela i-slab enezinga eliphezulu lokushisa eline-liquid core ukuvimbela ukuguga noma ukuqhekeka kwangaphakathi.Ngesikhathi esifanayo, ubuchwepheshe bokunciphisa i-liquid core bungenziwa kulesi sigaba ukuze kuthuthukiswe ikhwalithi ye-slab kanye nokuphumayo.Umfutho wamanzi nomthamo wamanzi wedivayisi yokupholisa yesibili kuyadingeka ukuthi ulungiseke ukuze uhlangabezane nezidingo zezinhlobo zensimbi ezihlukene kanye nesivinini sokudweba esihlukile.Umsebenzi we-level ye-tension ukunikeza amandla omdwebo we-billet futhi uqondise i-billet egobile, futhi ukhuthaze ukunyakaza kwedivayisi yokusika.Isivinini somdwebo we-billet sinomthelela omkhulu ekukhishweni nakwikhwalithi yokusakazwa okuqhubekayo.Umsebenzi wedivayisi eqondisayo ye-ingot ukuvimba ukuvuleka okuphansi kwesikhunta ngekhanda eliqondisayo le-ingot ngaphambi kokusakazwa okuqhubekayo, ukudonsa i-billet ngaphandle kwe-caster ngemva kokuba insimbi encibilikisiwe iqinile, unqamule ikhanda eliqondisayo le-ingot, futhi ufake induku eqondisayo. kudivayisi yokugcina.Imishini yokusika i-billet isika i-billet ngokuhamba okuqhubekayo ibe ubude obugxilile.Imishini yokusika evame ukusetshenziswa yi-flame cutter noma i-hydraulic shear kanye ne-swing shear.

Ngokuvamile, i-caster okuqhubekayoyakhiwe ngesithwali sensimbi esiwuketshezi (i-ladle netafula elijikelezayo), i-tundish kanye nomshini wayo oshintshayo, icrystallizer kanye nedivayisi yayo yokudlidliza, i-cooling zone yesibili yokupholisa i-clamping roller kanye nesistimu yamanzi okupholisa, okokuqondisa ukudweba, okokusika, idivayisi yokudweba ingot, njll. (njengoba kubonisiwe emfanekisweni ongezansi).I-Tundish idlala indima yokubhafa kanye nokuhlanza insimbi encibilikisiwe.Umthamo ngokuvamile u-20% ~ 40% womthamo we-ladle yensimbi encibilikisiwe.Ukugeleza kwe-caster ngaphezulu, amandla ayo amakhulu.Isikhunta "inhliziyo" yomshini wokuphonsa oqhubekayo, odinga ukuqhutshwa okuhle kokushisa, ukuqina kwesakhiwo, ukumelana nokugqoka kanye nokukhiqiza nokugcinwa okulula.Ngokuvamile yenziwe ngethusi elibomvu elibunjiwe noma ithusi elicijile, futhi udonga lwayo lwangaphandle luphoqeleka ukuba lupholiswe ngokulinganayo ngamanzi.Umsebenzi wedivayisi yokudlidliza isikhunta ukwenza isikhunta sidlidlize ngezikhathi ezithile ukuvimbela ukubopha phakathi kwegobolondo eliyinhloko nodonga lwesikhunta ukuthi lungaphulwa.Ijika lokudlidliza ngokuvamile liyashintsha ngokuvumelana nomthetho we-sinusoidal ukunciphisa umthelela.I-amplitude yayo kanye nemvamisa kufanele ihambisane eduze nesivinini sokudweba ukuze kuqinisekiswe ikhwalithi nokuphuma kwe-billet.Umshini wokupholisa wesibili ufakwa ngokushesha lapho kuphuma isikhunta.Umsebenzi wayo ukusheshisa ukuqiniswa kwe-slab nokulawula izinga lokushisa le-slab ngokusebenzisa isifutho samanzi noma ukupholisa i-atomization.I-pinch roll kanye ne-guide roll isekela i-slab enezinga eliphezulu lokushisa eline-liquid core ukuvimbela ukuguga noma ukuqhekeka kwangaphakathi.Ngesikhathi esifanayo, ubuchwepheshe bokunciphisa i-liquid core bungenziwa kulesi sigaba ukuze kuthuthukiswe ikhwalithi ye-slab kanye nokuphumayo.Umfutho wamanzi nomthamo wamanzi wedivayisi yokupholisa yesibili kuyadingeka ukuthi ulungiseke ukuze uhlangabezane nezidingo zezinhlobo zensimbi ezihlukene kanye nesivinini sokudweba esihlukile.Umsebenzi we-level ye-tension ukunikeza amandla omdwebo we-billet futhi uqondise i-billet egobile, futhi ukhuthaze ukunyakaza kwedivayisi yokusika.Isivinini somdwebo we-billet sinomthelela omkhulu ekukhishweni nakwikhwalithi yokusakazwa okuqhubekayo.Umsebenzi wedivayisi eqondisayo ye-ingot ukuvimba ukuvuleka okuphansi kwesikhunta ngekhanda eliqondisayo le-ingot ngaphambi kokusakazwa okuqhubekayo, ukudonsa i-billet ngaphandle kwe-caster ngemva kokuba insimbi encibilikisiwe iqinile, unqamule ikhanda eliqondisayo le-ingot, futhi ufake induku eqondisayo. kudivayisi yokugcina.Imishini yokusika i-billet isika i-billet ngokuhamba okuqhubekayo ibe ubude obugxilile.Imishini yokusika evame ukusetshenziswa yi-flame cutter noma i-hydraulic shear kanye ne-swing shear.

Ubude bangempela ukusuka ezingeni le-mold liquid kuya kumbhangqwana wokugcina we-tension straightening rollers ubude be-caster, okufanele buphindwe izikhathi ezingu-1.1-1.2 ubude be-metallurgical ye-caster.

Isikhathi sokuthumela: Apr-05-2022