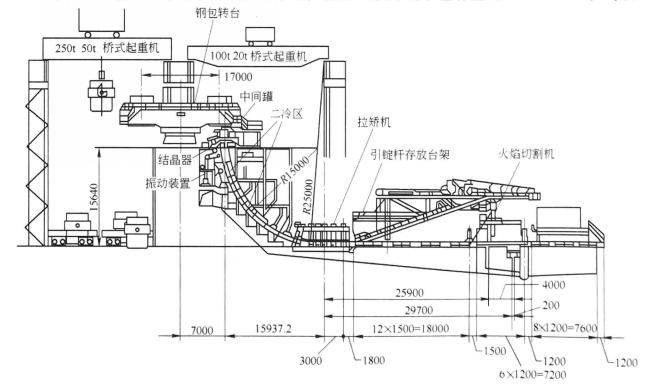

Feem ntau, covnruam casteryog tsim los ntawm cov khoom siv hlau ua kua (dawb thiab cov lus teb), tundish thiab nws cov cuab yeej hloov pauv, crystallizer thiab nws cov khoom vibration, thib ob qhov chaw txias txias clamping cov menyuam thiab cov dej txias, kos duab ncaj, txiav cov cuab yeej, ingot kos duab, thiab lwm yam (raws li qhia. hauv daim duab hauv qab no).Tundish plays lub luag hauj lwm ntawm buffering thiab purifying molten hlau.Lub peev xwm yog feem ntau 20% ~ 40% ntawm lub peev xwm ntawm molten steel ladle.Qhov ntau caster ntws, ntau dua nws lub peev xwm.Cov pwm yog "lub plawv" ntawm lub tshuab nruam nruam, uas yuav tsum tau ua kom zoo thermal conductivity, cov txheej txheem rigidity, hnav tsis kam thiab yooj yim tsim thiab txij nkawm.Nws feem ntau yog ua los ntawm forged liab tooj liab lossis cam khwb cia tooj dag, thiab nws cov phab ntsa sab nrauv raug yuam kom txias sib npaug los ntawm dej.Kev ua haujlwm ntawm cov pwm vibration cuab yeej yog ua kom cov pwm vibrate ib ntus kom tiv thaiv kev sib txuas ntawm lub plhaub thawj thiab cov pwm phab ntsa kom tsis txhob tawg.Lub vibration nkhaus feem ntau hloov raws li txoj cai sinusoidal kom txo tau qhov cuam tshuam.Nws qhov amplitude thiab zaus yuav tsum tau ua tib zoo sib xws nrog cov duab nrawm kom ntseeg tau tias qhov zoo thiab qhov tso tawm ntawm lub billet.Lub tshuab cua txias thib ob yog nruab tam sim ntawm qhov hluav taws xob ntawm cov pwm.Nws txoj haujlwm yog txhawm rau ua kom nrawm nrawm ntawm cov slab thiab tswj qhov ntsuas kub thiab ntsuas qhov ntsuas kub ntawm cov tshuaj tsuag dej lossis cov tshuaj tsuag atomization txias.Lub pinch yob thiab phau ntawv yob txhawb nqa qhov kub-kub slab nrog cov tub ntxhais ua kua kom tiv thaiv bulging deformation lossis sab hauv tawg.Nyob rau tib lub sijhawm, cov cuab yeej ua kua ua kua yuav ua tau nyob rau hauv seem no los txhim kho cov slab zoo thiab cov zis.Cov dej siab thiab dej ntim ntawm cov khoom siv cua txias thib ob yuav tsum tau kho kom tau raws li qhov xav tau ntawm cov hlau sib txawv thiab sib txawv qhov sib txawv.Lub luag haujlwm ntawm qhov nro leveler yog muab lub zog hluav taws xob kos duab thiab ncaj nraim rau lub pob tw, thiab txhawb kev txav ntawm cov cuab yeej txiav.Lub billet daim duab nrawm muaj qhov cuam tshuam zoo rau cov zis thiab qhov zoo ntawm kev nruam casting.Lub luag haujlwm ntawm ingot guiding device yog los thaiv qhov qis qhib ntawm pwm nrog lub ingot coj lub taub hau ua ntej nruam casting, rub lub billet tawm ntawm lub caster tom qab cov hlau molten solidifies, disconnect lub ingot guiding taub hau, thiab muab lub ingot guiding pas nrig. nyob rau hauv lub chaw cia khoom.Cov khoom siv txiav billet txiav cov billet nyob rau hauv tas li mus rau hauv taag ntev.Cov cuab yeej siv feem ntau yog hluav taws xob txiav lossis hydraulic shear thiab viav vias shear.

Feem ntau, covnruam casteryog tsim los ntawm cov khoom siv hlau ua kua (dawb thiab cov lus teb), tundish thiab nws cov cuab yeej hloov pauv, crystallizer thiab nws cov khoom vibration, thib ob qhov chaw txias txias clamping cov menyuam thiab cov dej txias, kos duab ncaj, txiav cov cuab yeej, ingot kos duab, thiab lwm yam (raws li qhia. hauv daim duab hauv qab no).Tundish plays lub luag hauj lwm ntawm buffering thiab purifying molten hlau.Lub peev xwm yog feem ntau 20% ~ 40% ntawm lub peev xwm ntawm molten steel ladle.Qhov ntau caster ntws, ntau dua nws lub peev xwm.Cov pwm yog "lub plawv" ntawm lub tshuab nruam nruam, uas yuav tsum tau ua kom zoo thermal conductivity, cov txheej txheem rigidity, hnav tsis kam thiab yooj yim tsim thiab txij nkawm.Nws feem ntau yog ua los ntawm forged liab tooj liab lossis cam khwb cia tooj dag, thiab nws cov phab ntsa sab nrauv raug yuam kom txias sib npaug los ntawm dej.Kev ua haujlwm ntawm cov pwm vibration cuab yeej yog ua kom cov pwm vibrate ib ntus kom tiv thaiv kev sib txuas ntawm lub plhaub thawj thiab cov pwm phab ntsa kom tsis txhob tawg.Lub vibration nkhaus feem ntau hloov raws li txoj cai sinusoidal kom txo tau qhov cuam tshuam.Nws qhov amplitude thiab zaus yuav tsum tau ua tib zoo sib xws nrog cov duab nrawm kom ntseeg tau tias qhov zoo thiab qhov tso tawm ntawm lub billet.Lub tshuab cua txias thib ob yog nruab tam sim ntawm qhov hluav taws xob ntawm cov pwm.Nws txoj haujlwm yog txhawm rau ua kom nrawm nrawm ntawm cov slab thiab tswj qhov ntsuas kub thiab ntsuas qhov ntsuas kub ntawm cov tshuaj tsuag dej lossis cov tshuaj tsuag atomization txias.Lub pinch yob thiab phau ntawv yob txhawb nqa qhov kub-kub slab nrog cov tub ntxhais ua kua kom tiv thaiv bulging deformation lossis sab hauv tawg.Nyob rau tib lub sijhawm, cov cuab yeej ua kua ua kua yuav ua tau nyob rau hauv seem no los txhim kho cov slab zoo thiab cov zis.Cov dej siab thiab dej ntim ntawm cov khoom siv cua txias thib ob yuav tsum tau kho kom tau raws li qhov xav tau ntawm cov hlau sib txawv thiab sib txawv qhov sib txawv.Lub luag haujlwm ntawm qhov nro leveler yog muab lub zog hluav taws xob kos duab thiab ncaj nraim rau lub pob tw, thiab txhawb kev txav ntawm cov cuab yeej txiav.Lub billet daim duab nrawm muaj qhov cuam tshuam zoo rau cov zis thiab qhov zoo ntawm kev nruam casting.Lub luag haujlwm ntawm ingot guiding device yog los thaiv qhov qis qhib ntawm pwm nrog lub ingot coj lub taub hau ua ntej nruam casting, rub lub billet tawm ntawm lub caster tom qab cov hlau molten solidifies, disconnect lub ingot guiding taub hau, thiab muab lub ingot guiding pas nrig. nyob rau hauv lub chaw cia khoom.Cov khoom siv txiav billet txiav cov billet nyob rau hauv tas li mus rau hauv taag ntev.Cov cuab yeej siv feem ntau yog hluav taws xob txiav lossis hydraulic shear thiab viav vias shear.

Qhov tseeb ntev los ntawm cov pwm ua kua theem mus rau qhov kawg ntawm qhov nro straightening rollers yog qhov ntev ntawm lub caster, uas yuav tsum yog 1.1-1.2 npaug ntawm qhov ntev ntawm lub caster.

Post lub sij hawm: Apr-05-2022