Roll Kho Submerged Arc Vuam

Roll kho submerged arc vuam yog ib qho muaj zog vuam arc faus vuam txoj kev, ntuj nyob rau hauv cov txheej txheem vuam tsis tuaj yeem pom cov arc, thiab feem ntau ntawm cov vuam tsis siv neeg, kev ua haujlwm tau zoo heev.Submerged arc vuam, lub hauv paus ntsiab lus ntawm kev xaiv lub vuam specification yog: kom ntseeg tau tias muaj qhov loj me, tsis muaj kev sib tw, tsis yog weld los ntawm, weld qog thiab lwm yam qhov tsis xws luag.Feem ntau siv txoj kev xaiv yog cov txheej txheem rooj, txoj kev sim, txoj kev ua pov thawj, txoj kev suav.Txawm hais tias siv txoj kev twg los txiav txim qhov tsis, yuav tsum tau kho nyob rau hauv daim ntawv thov ntawm vuam, kom ua tiav qhov zoo tshaj plaws thaum txuas txuas ntxiv.

Raws li kev siv tam sim no ntau yam ntawm monofilamentSubmerged arc vuam, thaum lub phaj thickness tsawg dua 14 hli, koj tsis tuaj yeem qhib lub bevel, sib dhos nrog qee qhov sib txawv;phaj thickness 14 ~ 22mm, feem ntau qhib V-shaped bevel;phaj thickness 22 ~ 50mm, qhib X-shaped bevel;rau boiler roj ladle thiab lwm cov hlab ntsha siab feem ntau siv U-puab lossis ob npaug U-puab bevel, kom ntseeg tau tias hauv qab txheej ntawm weld los ntawm thiab tshem tawm slag.Bevel processing txoj kev feem ntau siv ntug planing tshuab thiab roj txiav tshuab, yuav tsum muaj ib tug tej yam degree ntawm kev raug.Rau kev sib txuas ncaj nraim yuav tsum tau ntxiv rau ntawm ob qho kawg ntawm arc-priming phaj thiab arc-extinguishing phaj, thiaj li yuav txo tau cov arc-priming thiab lead-out defects.

Rau qhov chaw vuam tom qab cov welded qhov chaw, feem ntau yuav ua rau kom kub ua hauj lwm los yog sandblasting thiab lwm txoj kev los xyuas kom meej qhov zoo ntawm vuam.

In submerged arc vuam, feem ntau yuav tsum tau kho cov vuam tam sim no nrog tsis siv neeg arc voltage txuam.Cov yam ntxwv cuam tshuam rau vuam tam sim no yog: phaj thickness, vuam ceev, hlau txoj kab uas hla, thiab lwm yam.

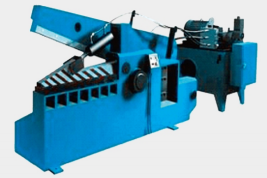

Vuam tshuab rau pob tw ncaj seam vuam

Cov txheej txheem vuam rau pob tw ncaj seam vuam yog: vuam ib leeg thiab ob sab vuam;ib txheej vuam thiab ntau txheej vuam;liner pad method thiab linerless method.Flux pad txoj kev submerged arc tsis siv neeg vuam, uas yog los tiv thaiv lub to ntawm slag thiab molten pas dej ua ke hlau, siv ib tug loj welding specification yog lub weld nkag mus rau ua tiav ob-sided sib sau.Kev tuav vuam capping submerged arc tsis siv neeg vuam, rau vuam seams uas tsis tuaj yeem siv liner, tuaj yeem ua ntej phau ntawv vuam capping thiab tom qab ntawdsubmerged arc vuam.Nyiaj siv ua haujlwm vuam, tsis muaj bevel, tsis muaj qhov sib txawv hauv qab vuam, nws tsis siv cov txheej txheem sib dhos sib txawv yog nruj heev.Txhawm rau kom ntseeg tau tias qhov kev nkag mus ntawm qhov vuam, kev vuam pem hauv ntej mus rau vuam los ntawm 40 mus rau 50%, rov qab vuam yuav tsum xyuas kom meej tias qhov vuam nkag ntawm 60 mus rau 70%.Hauv kev xyaum nws yog feem ntau nyuaj rau ntsuas qhov tob ntawm yaj, feem ntau yog los ntawm kev soj ntsuam cov xim ntawm sab nraum qab ntawm lub pas dej molten los txiav txim thiab kwv yees, yog li kom muaj qee qhov kev paub.Multi-txheej submerged arc vuam, rau tuab steel phaj siv ntau txheej vuam, txheej hauv qab ntawm vuam specifications yuav tsum me me, ob qho tib si los xyuas kom meej tias cov weld nkag mus, tab sis kuj kom tsis txhob tawg thiab lwm yam tsis xws luag.Txhua txheej ntawm cov pob qij txha yuav tsum tau staggered kom tsis txhob sib tshooj.

Butt nplhaib seam vuam technology

Covsubmerged arc vuam ntawm lub pob tw ntiv nplhaib seam ntawm lub tog raj kheej kheej kheej yuav tsum tau ua nrog lub log tsheb nrog cov cuab yeej tswj ceev.Yog tias yuav tsum tau siv ob sab welding, ib qho flux pad yuav tsum tau muab tso rau ntawm phab ntsa sab nrauv ntawm lub tog raj kheej hauv qab rau thawj zaug.Txhim kho lub welding trolley ntawm lub cantilever ncej thiab ncav mus rau hauv lub thoob kom welded tiaj tus.Weld hlau offset centerline nyob rau hauv txoj kab nqes welding txoj hauj lwm rau.Qhov thib ob frontal welding yog ua nyob rau sab nraum lub chim, nyob rau hauv lub Upper pav ca vuam.

Cross-joint welding technology

Rau T-pob txha thiab lub puab tsaig pob qij txha, ob daim ntawv ntawm lub nkoj zoo li vuam lossis bevel kaum vuam feem ntau yog siv, thiab rau lub kaum sab xis vuam, lub kaum sab xis ntawm cov hlau thiab lub vev xaib yog qhov zoo tshaj plaws ntawm 20 mus rau 30.°

Submerged arc semi-automatic vuam

Submerged arc semi-automatic vuam feem ntau yog siv nrog cov hlau hauv qab 2 hli, feem ntau yog rau cov welds, tab sis kuj rau pob tw welds.