Tokiso ea Rola e Kentsoeng ka Arc Welding

Ho lokisa li-arc tse ka tlas'a metsi ke matla tjheseletsa arc patoa tjheseletsa mokhoa, tlhaho ka tshebetso tjheseletsa a ke ke a bona arc, 'me boholo ba tjheseletsa othomathike, maemo a mosebetsi o ntlafala haholo.Welding ea arc e ka tlas'a metsi, molao-motheo oa ho khetha litlhaloso tsa tjheseletsa ke: ho etsa bonnete ba hore ho na le arc e tsitsitseng e tukang, sebōpeho le boholo ba weld ho finyella litlhoko, bokaholimo bo thehoa boreleli ebile bo le makhethe, ha ho na li-pores tse ka hare, slag, mapetsong, ha li cheselle, hlahala ea weld le tse ling. mefokolo.Mekhoa ea khetho e sebelisoang hangata ke mokhoa oa tafole, mokhoa oa teko, mokhoa oa ho etsa liteko, mokhoa oa ho bala.Ho sa tsotellehe hore na ke mokhoa ofe o sebelisetsoang ho fumana litekanyo, o tlameha ho lokisoa ha ho sebelisoa tjheseletsa, ho finyella katleho ka ho fetisisa ha o tsoela pele.

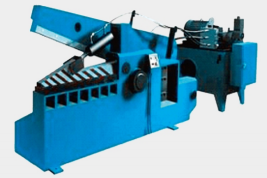

Ho ea ka mefuta e teng hona joale ea monofilamentWelding ea arc e ka tlas'a metsi, ha botenya ba poleiti bo ka tlase ho 14mm, u ke ke ua bula bevel, kopano ka lekhalo le itseng;botenya ba poleiti 14 ~ 22mm, hangata bo bulehile bevel e bōpehileng joaloka V;botenya ba poleiti 22 ~ 50mm, bevel e bulehileng ea sebopeho sa X;bakeng sa boiler khase ladle le lijana tse ling khatello hangata sebelisa U-shaped kapa habeli U-shaped bevel, ho etsa bonnete ba hore lera e ka tlaase ea weld ka le ho felisa slag.Mekhoa ea ho sebetsana le bevel hangata e sebelisa mochini oa ho rala le mochini o sehang khase, ho lokela ho ba le tekanyo e itseng ea ho nepahala ha ts'ebetso.Bakeng sa manonyeletso a seam a otlolohileng a lokela ho eketsoa lipheletsong tse peli tsa poleiti ea arc-priming le poleiti ea ho tima arc, e le ho fokotsa liphoso tsa arc-priming le lead-out.

Bakeng sa letheba tjheseletsa ka mor'a likarolo welded, ka kakaretso ho eketsa mocheso sebetsa kapa sandblasting le mekhoa e meng ho etsa bonnete ba hore boleng ba tjheseletsa.

In tjheseletso e ka tlasa metsi, ka kakaretso hoa hlokahala ho lokisa hona joale oa welding ka othomathike arc voltage matching.Lintlha tse amang hona joale oa ho tjheseletsa ke: botenya ba poleiti, lebelo la ho tjheseletsa, bophara ba terata, jj.

Theknoloji ea welding bakeng sa welding e otlolohileng ea seam

Mekhoa ea ho tjheseletsa bakeng sa butt otlolohile seam welding ke: ho tjheseletsa ka lehlakore le le leng le ho tjheseletsa ka mahlakoreng a mabedi;tjheseletsa e nang le lera le le leng le tjheseletsa e nang le dikarolo tse ngata;mokhoa oa liner pad le mokhoa o se nang liner.Mokhoa oa Flux pad submered arc automatic welding, e leng ho thibela ho lutla ha slag le tšepe e qhibilihisitsoeng ea letamo, ho sebelisa litlhaloso tse kholoanyane tsa welding ke ho kenella ha weld ho fihlela sebopeho sa mahlakore a mabeli.Manual welding capping submered arc automatic welding, bakeng sa seams welding e ke keng ea sebelisa liner, e ka qala ka letsoho tjheseletsa capping ebe joaletjheseletso e ka tlasa metsi.Overhead tjheseletsa, bakeng sa ho se bevel, ha ho lekhalo butt tjheseletsa, ha a sebelise leha e le efe liner kopano lekhalo ditlhoko li thata haholo.E le ho etsa bonnete ba hore ho kena tjheseletsa, ka pele tjheseletsa ho weld ka 40 ho 50%, morao tjheseletsa lokela ho etsa bonnete ba hore tjheseletsa ho kenella ka 60 ho 70%.Ka kakaretso ho thata ho lekanya botebo ba ho qhibiliha, hangata ka ho shebella 'mala oa mokokotlo oa letamo le qhibilihisitsoeng ho ahlola le ho lekanya, kahoo ho ba le phihlelo e itseng.Multi-layer submerged arc welding, bakeng sa poleiti e teteaneng ea tšepe ho sebelisa li-welding tse ngata, karolo e ka tlase ea litlhaloso tsa tjheseletsa e lokela ho ba nyane, ka bobeli ho etsa bonnete ba hore ho kenella ha weld, empa hape ho qoba ho phunyeha le liphoso tse ling.Karolo e 'ngoe le e' ngoe ea li-weld e lokela ho sisinyeha hore e se ke ea kopana.

Theknoloji ea ho tjheseletsa butt ring seam

Thetjheseletso e ka tlasa metsi ea butt ring seam ea cylinder e chitja e lokela ho etsoa ka thaere ea rolara e nang le sesebelisoa sa ho laola lebelo.Haeba ho hlokahala hore ho be le tjheseletsa e mahlakoreng a mabeli, phallo ea flux e tlameha ho behoa leboteng le ka ntle la silinda e ka tlase bakeng sa phallo ea pele.Lokisa trolley ea welding holim'a foreime ea cantilever 'me u fihle tlase ho barrel ho cheselletsa sephara.Weld wire offset centerline tlas'a letsoapo tjheseletsa boemo ba.Welding ea bobeli e ka pele e etsoa ka ntle ho moqomo, sebakeng se ka holimo se sephara.

Theknoloji ea ho tjheseletsa ka kopanelo

Bakeng sa manonyeletso a T le lap, hangata ho sebelisoa mefuta e 'meli ea tjheseletsa e bōpehileng joaloka sekepe kapa ea bevel angle, 'me bakeng sa tjheseletsa ea angle e bataletseng, angle pakeng tsa terata le tepo e bolokiloe hantle ho 20 ho isa ho 30.°

Welding e ka tlas'a metsi arc semi-automatic welding

Welding e kentsoeng ka tlas'a metsi arc semi-automatic welding hangata e sebelisoa ka terata e ka tlase ho 2mm, haholo bakeng sa li-welds tsa fillet, empa le bakeng sa li-welds tsa butt.