Ukulungisa I-Roll I-Summerged Arc Welding

Roll ukulungisa i-arc welding engaphansi iyindlela eqinile yokushisela i-arc engcwatshwe indlela yokushisela, yemvelo enqubweni yokushisela ayikwazi ukubona i-arc, futhi iningi le-welding ezenzakalelayo, izimo zabasebenzi ziba ngcono kakhulu.I-arc welding engaphansi kwamanzi, isimiso sokukhetha ukucaciswa kwe-welding siwukuthi: ukuqinisekisa i-arc evuthayo ezinzile, ukuma kwe-weld kanye nosayizi ukuze kuhlangatshezwane nezidingo, ubuso bakheka bushelelezi futhi bucocekile, akukho zimbotshana zangaphakathi, i-slag, imifantu, hhayi i-weld ngokusebenzisa, isimila se-weld nokunye. amaphutha.Izindlela zokukhetha ezisetshenziswa kakhulu yindlela yethebula, indlela yokuhlola, indlela ye-empirical, indlela yokubala.Kungakhathaliseki ukuthi iyiphi indlela esetshenziselwa ukunquma imingcele, kufanele ilungiswe ekusetshenzisweni kwe-welding, ukuze kuzuzwe okuphumelelayo kakhulu lapho i-welding eqhubekayo.

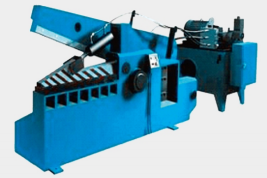

Ngokobubanzi bamanje obusebenzayo be-monofilamentI-arc welding engaphansi kwamanzi, lapho ubukhulu bepuleti bungaphansi kuka-14mm, awukwazi ukuvula i-bevel, umhlangano ngegebe elithile;ukujiya kwepuleti 14 ~ 22mm, i-bevel evamile evulekile efana ne-V;ubukhulu bepuleti 22 ~ 50mm, i-bevel evulekile emise okwe-X;I-boiler gas ladle kanye neminye imikhumbi yokucindezela ngokuvamile isebenzisa i-bevel emise oku-U noma ephindwe kabili e-U, ukuze kuqinisekiswe ukuthi ungqimba olungezansi lwe-weld ludlula futhi lususe i-slag.Izindlela zokucubungula i-bevel zivame ukusebenzisa umshini wokuhlela onqenqemeni kanye nomshini wokusika igesi, kufanele kube nezinga elithile lokucubungula ngokunemba.Ukuze kuhlanganiswe ama-seam aqondile kufanele kwengezwe kuzo zombili iziphetho ze-arc-priming plate kanye ne-arc-extinguishing plate, ukuze kuncishiswe i-arc-priming kanye nezinkinga zokuhola.

Ukuze indawo Welding emva izingxenye ashiselwe, ngokuvamile ukwandisa izinga lokushisa ukusebenza noma sandblasting kanye nezinye izindlela ukuqinisekisa izinga Welding.

In ukushisela i-arc emanzini, ngokuvamile kuyadingeka ukulungisa i-welding current nge-automatic arc voltage match.Izici ezithinta i-welding current yilezi: ubukhulu bepuleti, isivinini sokushisela, ububanzi bezintambo, njll.

Ubuchwepheshe be-Welding bokushisela i-butt straight seam

Izindlela zokushisela ze-butt straight seam welding yilezi: ukushisela ohlangothini olulodwa kanye nokushisela okunezinhlangothi ezimbili;i-welding eyodwa-ungqimba kanye ne-multi-layer welding;indlela ye-liner pad kanye nendlela ye-linerless.Indlela ye-Flux pad engaphansi kwe-arc yokushisela okuzenzakalelayo, okuwukuvimbela ukuvuza kwe-slag nensimbi yechibi elincibilikisiwe, ukusebenzisa ukucaciswa kokushisela okukhudlwana kuwukungena kwe-weld ukuze kuzuzwe ukwakheka okukabili.I-Manual welding capping i-arc automatic yelding, ye-welding seams engakwazi ukusebenzisa i-liner, ingaqala ngokufaka i-welding capping ngesandla bese emva kwalokho.ukushisela i-arc emanzini.Welding Overhead, ngoba akukho bevel, akukho igebe butt Welding, akasebenzisi noma yiziphi izidingo liner igebe umhlangano ziqine kakhulu.Ukuze kuqinisekiswe ukuthi ukungena kokushisela, ukushisela ngaphambili ukushisela ngokusebenzisa u-40 kuya ku-50%, ukushisela emuva kufanele kuqinisekise ukuthi ukungena kwe-weld ka-60 kuya ku-70%.Ngokusebenza ngokuvamile kunzima ukukala ukujula kokuncibilika, ngokuvamile ngokubheka umbala ongemuva wechibi elincibilikisiwe ukuze wahlulele futhi ulinganise, ukuze ube nolwazi oluthile.I-Multi-layer submerged arc welding, ukuze ipuleti lensimbi eliwugqinsi lisebenzise i-welding ye-multi-layer, ungqimba olungezansi lokucaciswa kokushisela lube luncane, kokubili ukuqinisekisa ukuthi ukungena kwe-weld, kodwa futhi nokugwema ukuqhekeka nezinye iziphambeko.Ingqimba ngayinye yamajoyinti okushisela kufanele inyakaze ukuze ingadluleli.

Ubuchwepheshe bokushisela i-Butt ring seam

Iukushisela i-arc emanzini we-butt ring seam yesilinda esiyindilinga kufanele yenziwe ngesondo le-roller elinomshini wokulawula isivinini.Uma kudingeka ukushisela okunezinhlangothi ezimbili, i-flux pad kufanele ibekwe endaweni engaphandle yodonga lwesilinda ngezansi ukuze kudlule kuqala.Lungisa i-welding trolley kuhlaka lwe-cantilever bese ufika phansi emgqonyeni ukuze ushise isicaba.I-Weld wire offset centerline ngaphansi kwendawo yokushisela eyehlelayo.I-welding yesibili yangaphambili yenziwa ngaphandle komgqomo, endaweni engaphezulu ye-welding.

Ubuchwepheshe be-welding obuhlangene

Kumajoyinti e-T nama-lap joints, izinhlobo ezimbili zokushisela okumise okwemikhumbi noma i-bevel angle welding zivame ukusetshenziswa, futhi ekushiseleni i-engeli eyisicaba, i-engeli ephakathi kocingo newebhu igcinwa kangcono ku-20 kuya ku-30.°

I-arc engaphansi kwe-semi-automatic welding

I-arc semi-automatic welding engaphansi kwamanzi ivame ukusetshenziswa ngocingo olungaphansi kuka-2mm, ikakhulukazi ukushisela i-fillet, kodwa futhi nokushisela izinqe.