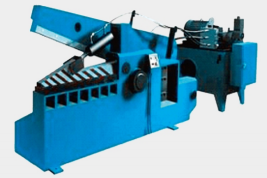

Qalab Qabow Aluminium Foil Aluminium Gariiradda Mashiinka Samaynta

| Meesha Asal ahaan | Guangxi, Shiinaha | Awood | 500-10000 |

| Magaca Summada | Runxiang | Cabbirka (L*W*H) | 1.7*1.3*1.5 |

| Nooca | Hot Rolling Mill | Dammaanad | 1 Sano |

| Xaalad | Cusub | Qodobbada Iibka Muhiimka ah | Wax soo saar sare |

| Warbixinta Tijaabada Mashiinada | Bixiyay | Warshadaha lagu dabaqi karo | Dukaamada Qalabka Dhismaha, Warshada Wax soo saarka, Tafaariiqda, Hawlaha dhismaha |

| Nooca Suuqgeynta | Badeeco Cusub 2023 | Magaca alaabta | Foil Rolling Mill |

| Dammaanadda qaybaha asaasiga ah | 1 Sano | Midabka | Mid kasta |

| Qaybaha xudunta u ah | PLC, Engine, Gearbox, Motor, Gear | Heerka | Habaynta |

| Voltage | 380V/6000V | Materiyada ceeriin | Billet tuurista joogtada ah |

Aluminium foil roughing Mill waa mishiinka rogo xaashida aluminiumka iyo gariiradaha xariijimaha leh oo leh walxo 0.5mm ah ama ka yar iyada oo loo marayo dhowr baas si ay uga dhigaan bireed aluminium ah 2 × 0.0045mm ama dhumuc ka badan.

Hordhaca aluminiumfoornada duubista.

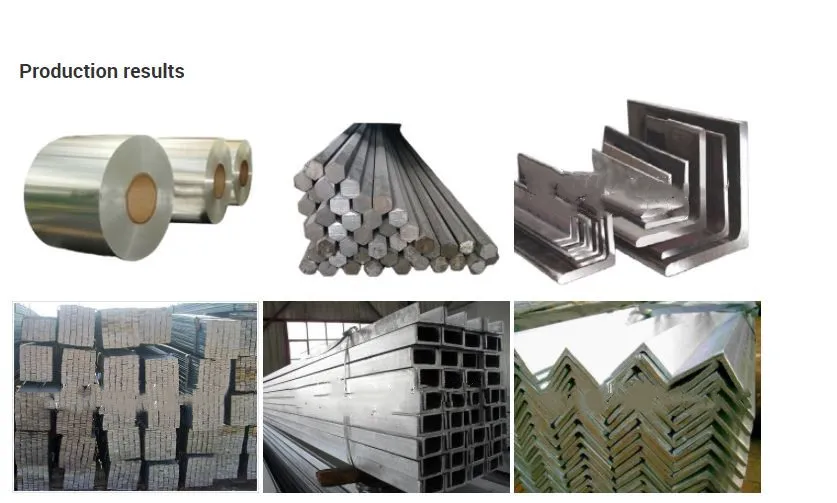

Mashiinno iyo qalab warshadeed oo aluminium ah oo inta badan loo isticmaalo duubista, farsamaynta iyo sifaynta

Hawlgalka iyo qodobbada muhiimka ah

Hawlgalka iyo qodobbada muhiimka ah

1. diyaarinta hore ee duubista

1.1 Hubi heerka uu ku shaqeeyo nidaam kasta si aad u xaqiijiso

1.2 U beddel duubabka si waafaqsan jadwalka oo hubi

a) booska heerka sanka, xannibaadda

b) Xaqiiji booska xariiqda duubista

c) Isku xirka dhuumaha ceeryaamo saliida waa inuu ahaadaa mid wanaagsan

1.3 Diyaari oo u rar walxaha si waafaqsan qorshaha una fiirso

a) Ka saar lakabka sare si aad uga ilaaliso boodhka iyo cajaladaha inay soo galaan mishiinka si looga hortago calaamadaha duubista

b) Xaqiiji tayada wejiga dhamaadka duubka?Nabaro fiiqan oo khafiif ah ayaa lagu xalliyay qaab wareegsan.

2. Habka dardargelinta

2.1 Cusub oo loo beddelay duubista shaqada

2.1.1 Kuleyli duubabka 3 ~ 5min iyadoo loo eegayo xaalada socodka duubista ee caadiga ah;duubabka kululaynta ayaa yarayn kara.

2.1.2 AFC ee xakamaynta saamiga saliidda buufinta ee xadka hoose ee miiska geeddi-socodka ayaa si dhakhso ah u gaari kara qaabka saxanka ugu fiican ka dib soo kabashada.

2.1.3 Isticmaal xiisadda ka dib iyo xiisadda ka hor ee suurtogalka ah ee ugu weyn si aad u dejiso soo kabashada ka dib.

2.1.4 Isticmaal xoog-rogid ku habboon, cudud duudduubka foorarsan, qiimaha leexin?Inta badan ku tiirsanow ururinta waayo-aragnimada caadiga ah si aad uga fogaato hal dhinac dabacsan, hal dhinac cidhiidhi ah ama labada dhinac aad u dabacsan oo aad u cidhiidhi ah.

2.1.5 Xawaare sida ugu dhakhsaha badan si aad u gaarto dhumucda la beegsanayo.

2.2 Habka duubista caadiga ah ayaa dedejisa

2.2.1 Marka loo eego qiimaha halbeeg kasta oo ka mid ah xoogga duuduubka hore ee duudduuban, foorarsiga xoogga duudduuban, qiimaha foorarsiga wuxuu heli karaa qaab saxan siman.

2.2.2 Xawaaraha waxaa lagu kordhin karaa hal talaabo si aan la isku hagaajin saxanka ka hor inta dhumucda bartilmaameedku aanu yarayn qiimaha xiisaddu kuma fidinayso faafinta.

2.3 Habaynta silbashada iyo tollaynta furfuran inta lagu jiro kor u kaca xawliga ayaa inta badan ku jira duubid qallafsan oo afar jeer ah.

2.3.1 Yaree waqtiga qallooca duuduubka kordhinta xoogga duubista waxay kordhisaa xiisadda dhabarka ee ku habboon inay kordhiso xiisadda hore.

2.3.2 Hagaajinta xaaladaha saliidda adigoo isticmaalaya heerkulka saliidda hoose ee furan ee saliidda buufinta badanaa furan.

2.3.3 Ilaa hadda lama duubi karo marka liiska la beddelo.

3. Habka duubista dhexdhexaadka ah

3.1 Isku-xidhka wanaagsan, gaar ahaan walxo ballaaran ayaa soo saari doona dhinac dabacsan iyo dhinac adag, taas oo keenaysa cirifka dillaacsan ee feeraha labaad ee ifafaale dabacsan ayaa saameeya wax soo saarka soo socda.

3.2 AFC waa in si joogto ah loo cabbiraa duubka nooca saxan eber ee xaalad orod ah.

3.3 Marka feeraha labaad dabacsan yahay, saamiga buufinta saliidda ee AFC waa la dhimi karaa.

3.4 Suunka jaban ee qashinka saliidda lagu dhaqo muddo dheer waa in lagu buufiyaa saliid dhamaantood furan si looga fogaado isbedelka nooca rullaluistemadka.

3.5 Hagaajinta marka la duuduubo, laalaabayo, lakabka xadhigga, duub dabacsan