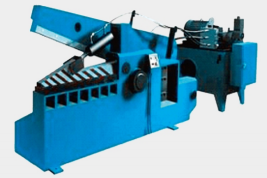

Cold Mill Aluminum Foil Aluminum Coil Yin Machine

| Wurin Asalin | Guangxi, China | Ƙarfi | 500-10000 |

| Sunan Alama | Runxiang | Girma (L*W*H) | 1.7*1.3*1.5 |

| Nau'in | Hot Rolling Mill | Garanti | Shekara 1 |

| Yanayi | Sabo | Mabuɗin Siyarwa | Babban Haɓakawa |

| Rahoton Gwajin Injin | An bayar | Masana'antu masu dacewa | Shagunan Kayayyakin Gina, Shuka Masana'antu, Dillali, Ayyukan Gine-gine |

| Nau'in Talla | Sabon samfur 2023 | Sunan samfur | Foil Rolling Mill |

| Garanti na ainihin abubuwan haɗin gwiwa | Shekara 1 | Launi | Kowa |

| Abubuwan Mahimmanci | PLC, Injin, Gearbox, Motoci, Gear | Daidaitawa | Keɓancewa |

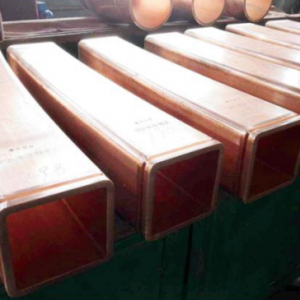

| Wutar lantarki | 380V/6000V | Danyen abu | Ci gaba da fitar da billet |

Aluminum foil roughing niƙa inji ne da ke jujjuya takardar aluminum da tsiri coils tare da kayan 0.5mm ko ƙasa da haka ta hanyar wucewa da yawa don sanya su cikin foil na aluminum na 2 × 0.0045mm ko fiye da kauri.

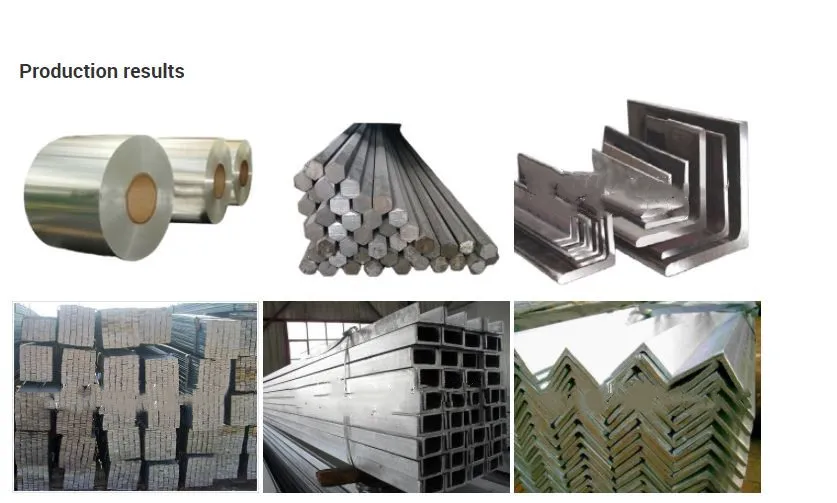

Gabatarwar aluminumtsare mirgina niƙa.

Saitin injunan masana'antar aluminium da kayan aikin da aka fi amfani da su don birgima, sarrafawa da tacewa.

Aiki da mahimman bayanai

Aiki da mahimman bayanai

1. Pre-mirgina shiri

1.1 Bincika matsayin aiki na kowane tsarin don tabbatarwa

1.2 Canza rolls bisa ga jadawalin kuma duba

a) Matsayin nozzle, toshewa

b) Tabbatar da matsayin layin mirgina

c) Haɗin bututun hazo ya kamata ya zama mai kyau

1.3 Shirya da ɗora kayan bisa ga shirin kuma kula da su

a) Cire shimfidar wuri don hana ƙura da tef shiga cikin niƙa don hana alamar birgima

b) Tabbatar da ingancin fuskar ƙarshen nadi?Ƙunƙasa masu kaifi masu haske waɗanda aka sarrafa zuwa siffa mai zagaye.

2. Tsarin sauri

2.1 Sabbin canje-canje zuwa mirgina aikin

2.1.1 Heat da rolls for 3 ~ 5min bisa ga al'ada mirgina yi yanayin Gudun;Rolls masu zafi na iya zama ƙasa da ƙasa.

2.1.2 AFC a cikin bututun ƙarfe man fesa rabo iko a cikin ƙananan iyaka na tsari tebur iya sauri isa manufa farantin siffar bayan dawo da.

2.1.3 Yi amfani da mafi girman yiwuwar bayan tashin hankali da tashin hankali don daidaitawa bayan dawowar.

2.1.4 Yi amfani da ƙarfin mirgina da ya dace, ƙarfin jujjuyawar lanƙwasa, ƙimar karkata?Yafi dogara ga tarin gwaninta na yau da kullun don gujewa sako-sako da gefe ɗaya, gefe ɗaya matse ko duka bangarorin biyu ma sako-sako da matsewa.

2.1.5 Yi sauri da wuri-wuri don isa kauri da aka yi niyya.

2.2 Tsarin mirgina na yau da kullun yana saurin haɓakawa

2.2.1 Dangane da ƙimar kowane siga na babban mirgine saiti na mirgina ƙarfi, lankwasawa yi ƙarfi, karkatar da darajar na iya samun santsi farantin siffar.

2.2.2 Ana iya ƙara saurin gudu a mataki ɗaya don kada a daidaita farantin kafin kauri mai ƙima ya kasance ƙananan ƙimar tashin hankali ba ya dace da yadawa.

2.3 Yin sarrafa zamewa da buɗaɗɗen kabu yayin hawan saurin ya fi girma a cikin mirgina sau huɗu.

2.3.1 Rage lokacin nakasar mirgina ƙara ƙarfin mirgina ƙara ƙarfin baya wanda ya dace don ƙara tashin hankali na gaba.

2.3.2 Inganta yanayin lubrication ta amfani da ƙananan zafin mai buɗaɗɗen kabu a man fesa sau da yawa buɗewa.

2.3.3 Har yanzu ba za a iya mirgina ba lokacin da lissafin ya canza.

3. Tsarin mirgina tsaka-tsaki

3.1 Kyakkyawan daidaitawa, musamman kayan abu mai faɗi zai haifar da gefe maras kyau da kuma m gefe, don haka haifar da fashe gefen haƙarƙari na biyu sako-sako da abin mamaki na gaba.

3.2 AFC ya kamata a kasance a kai a kai calibrated sifili nau'in faranti a cikin yanayin aiki.

3.3 Lokacin da haƙarƙari na biyu ya kwance, ana iya rage rabon feshin mai a cikin AFC.

3.4 Kargataccen bel tare da sharar mai na dogon lokaci yakamata a fesa mai duk a buɗe don guje wa canjin nau'in abin nadi.

3.5 Daidaita lokacin wrinkling, folding, kirtani Layer, sako-sako da yi