Cold Mill Aluminium Foil Aluminium Coil Make Machine

| Sebaka sa Tšimoloho | Guangxi, Chaena | Matla | 500-10000 |

| Lebitso la Brand | Runxiang | Dimension(L*W*H) | 1.7*1.3*1.5 |

| Mofuta | Hot Rolling Mill | Tiisetso | 1 Selemo |

| Boemo | E ncha | Lintlha tsa bohlokoa tsa ho rekisa | Tlhahiso e Phahameng |

| Tlaleho ea Teko ea Mechini | Fanetsoe | Liindasteri tse sebetsang | Mabenkele a Lisebelisuoa tsa Kaho, Setsi sa Tlhahiso, Mabenkele, Mesebetsi ea kaho |

| Mofuta oa Papatso | Sehlahisoa se Secha sa 2023 | Lebitso la sehlahisoa | Foil Rolling Mill |

| Warranty ea likarolo tsa mantlha | 1 Selemo | Mmala | Leha e le efe |

| Likaroloana tsa mantlha | PLC, Enjene, Gearbox, Motor, Gear | Standard | Boikemisetso |

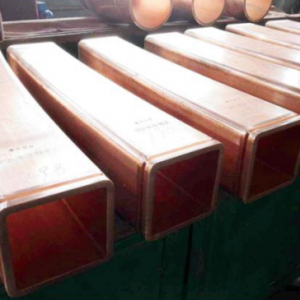

| Palo ea li-volts | 380V/6000V | Lintho tse tala | Billet e tsoelang pele |

Aluminium foil roughing leloala ke mochine o rollang lakane ea aluminium le li-coil tse hlobolang ka thepa ea 0.5mm kapa ka tlase ho feta ka litsela tse 'maloa ho etsa hore e be foil ea aluminium ea 2×0.0045mm kapa botenya ho feta.

Kenyelletso ea aluminiumfoil rolling leloala.

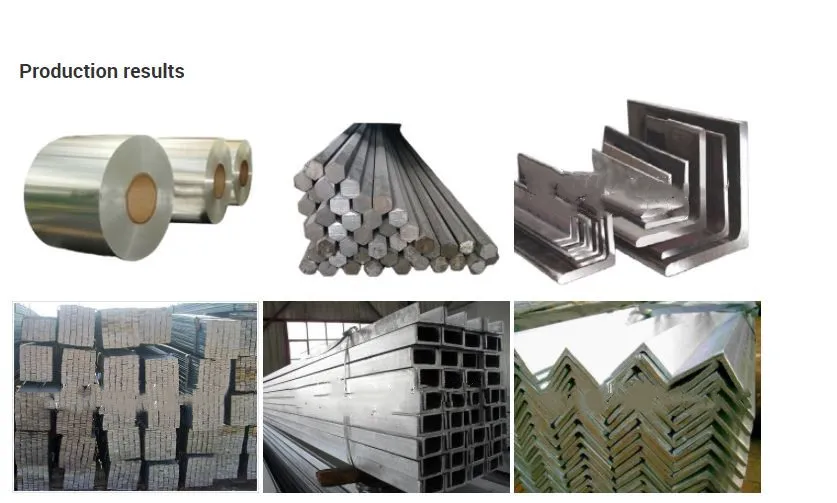

Sete ea mechini ea indasteri ea aluminium le lisebelisoa tse sebelisoang haholo bakeng sa ho roala foil, ho sebetsa le ho hloekisoa.

Ts'ebetso le lintlha tsa bohlokoa

Ts'ebetso le lintlha tsa bohlokoa

1. Tokisetso pele ho rolling

1.1 Sheba boemo ba ts'ebetso ea sistimi ka 'ngoe ho netefatsa

1.2 Fetola meqolo ho latela kemiso le ho hlahloba

a) Boemo ba boemo ba Nozzle, ho thibela

b) Netefatsa boemo ba mola o kolohang

c) Khokahano ea peipi ea moholi oa oli e lokela ho ba hantle

1.3 Lokisetsa le ho kenya thepa ho latela moralo le ho ela hloko

a) Tlosa bokaholimo ho thibela lerole le teipi ho kena leloaleng ho thibela matšoao

b) Netefatsa boleng ba sefahleho sa moqolo?Matetetso a nchocho a bobebe a nang le sebopeho se chitja.

2. Ts'ebetso ea ho potlakisa

2.1 E sa tsoa fetoloa molemong oa ho qala mosebetsi

2.1.1 Chesa meqolo bakeng sa 3 ~ 5min ho ea ka mokhoa o tloaelehileng oa ho tsamaisa rolling;meqolo e futhumetseng e ka fokotseha.

2.1.2 AFC taolong ea karo-karolelano ea sefaha sa oli ea nozzle moeling o ka tlase oa tafole ea tšebetso e ka fihla ka potlako sebopeho se loketseng sa poleiti kamora ho hlaphoheloa.

2.1.3 Sebelisa matla a maholo ka ho fetisisa a ka bang teng ka mor'a tsitsipano le pele ho tsitsipano ho tsitsisa ka mor'a ho hlaphoheloa.

2.1.4 Sebelisa matla a loketseng a ho bilika, matla a ho kobeha, boleng ba ho thetheha?Haholo-holo itšetlehe ka ho bokellana ka mokhoa o tloaelehileng ho qoba lehlakore le le leng le hlephileng, lehlakoreng le leng le le thata kapa mahlakore ka bobeli a hlephileng le a thata haholo.

2.1.5 Potlakisa kapele kamoo ho ka khonehang ho fihlela botenya ba sepheo.

2.2 Ho potlakisa ho potlakisa ho tloaelehileng

2.2.1 Ho ea ka boleng ba paramethara e 'ngoe le e' ngoe ea matla a holimo a setiloe esale pele, matla a ho kobeha, boleng ba ho sekama bo ka fumana sebopeho sa poleiti e boreleli.

2.2.2 Lebelo le ka eketsoa ka mohato o le mong ho se fetole poleiti pele sepheo sa sepheo se batla se le senyenyane sa tsitsipano ha se khone ho jala.

2.3 Ts'ebetso ea ho thella le ho robeha ha seam nakong ea ho phahama ka lebelo ho haholo-holo ka ho bilika ho thata ka makhetlo a mane.

2.3.1 Khutsufatsa nako ea ho roala deformation eketsa matla rolling eketsa tsitsipano morao loketseng ho eketsa tsitsipano ka pele.

2.3.2 Ntlafatsa maemo a ho tlotsa ka ho sebelisa mocheso o tlase oa oli o bulehileng seam ho oli ea fafatsa hangata e bulehang.

2.3.3 E ntse e ke ke ea phuthoa ha moqolo o fetoha.

3. Ts'ebetso ea ho phutha lipakeng

3.1 Ho tsamaisana hantle, haholo-holo thepa e pharaletseng e tla hlahisa lehlakore le hlephileng le lehlakoreng le thata, kahoo ho baka hore bohale bo phunyehileng ba ntho ea bobeli bo hlephileng bo ama tlhahiso e latelang.

3.2 AFC e lokela ho lekanyetsoa khafetsa lirolo tsa mofuta oa zero maemong a ho sebetsa.

3.3 Ha likhopo tsa bobeli li hlephile, karolelano ea sefafatsi sa oli ho AFC e ka fokotsoa.

3.4 Lebanta le robehileng le nang le litšila tsa oli nako e telele le lokela ho fafatsoa ka oli e butsoe kaofela ho qoba phetoho ea mofuta oa rolara.

3.5 Tokiso ha ho sosobana, ho mena, lera la likhoele, moqolo o hlephileng